Preparation method of L-shaped precast terrazzo decoration hanging board

A technology for decorative hanging boards and terrazzo, which is applied to manufacturing tools, ceramic molding machines, floors, etc., can solve the problems of obvious difference between the decorative effect and the bottom surface, troublesome production process, and high maintenance cost, achieve spectacular and generous effects, and improve water glue. ratio, the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

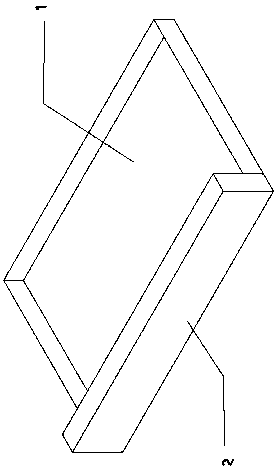

[0033] Such as figure 1 As shown, the present invention discloses an L-shaped prefabricated terrazzo decorative hanging board, which is composed of a corner part 2 and a plane part 1. The preparation method of the decorative hanging board includes the following steps:

[0034] A. Raw material preparation

[0035] Preparation of ordinary concrete: Use 280 parts of P.Ⅱ 52.5 cement, mix with 50 parts of fly ash, 750 parts of river sand, 1050 parts of crushed stone, 3 parts of polycarboxylate high-performance water reducer and 150 parts of water, mix well and set aside ;

[0036] Preparation of terrazzo concrete: Use 900 parts of P.W 42.5 white cement, mix with 550 parts of white rice stone, 550 parts of black rice stone, 5 parts of polycarboxylate high-performance water reducer and 250 parts of water, stir well and set aside;

[0037] The water reducing rate of the above polycarboxylate high-performance water reducing agent is 25%;

[0038] B. Mold cleaning and placement

[0...

Embodiment 2

[0049] Such as figure 1 As shown, the present invention discloses an L-shaped prefabricated terrazzo decorative hanging board, which is composed of a corner part 2 and a plane part 1. The preparation method of the decorative hanging board includes the following steps:

[0050] A. Raw material preparation

[0051] Preparation of ordinary concrete: Use 300 parts of P.Ⅱ 52.5 cement, mix with 60 parts of fly ash, 800 parts of river sand, 1100 parts of gravel, 4 parts of polycarboxylate high-performance water reducer and 160 parts of water, stir well and set aside ;

[0052]Preparation of terrazzo concrete: Use 950 parts of P.W 42.5 white cement, mix with 600 parts of white rice stone, 600 parts of black rice stone, 8 parts of polycarboxylate high-performance water reducer and 280 parts of water, stir well and set aside;

[0053] The water reducing rate of the above polycarboxylate high-performance water reducing agent is 27%;

[0054] B. Mold cleaning and placement

[0055] Mo...

Embodiment 3

[0065] Such as figure 1 As shown, the present invention discloses an L-shaped prefabricated terrazzo decorative hanging board, which is composed of a corner part 2 and a plane part 1. The preparation method of the decorative hanging board includes the following steps:

[0066] A. Raw material preparation

[0067] Preparation of ordinary concrete: Use 330 parts of P.Ⅱ 52.5 cement, mix 70 parts of fly ash, 815 parts of river sand, 1150 parts of crushed stone, 5 parts of polycarboxylate high-performance water reducer and 170 parts of water, stir well and set aside ;

[0068] Preparation of terrazzo concrete: Use 1000 parts of P.W 42.5 white cement, mix with 650 parts of white rice stone, 650 parts of black rice stone, 10 parts of polycarboxylate high-performance water reducer and 300 parts of water, stir well and set aside;

[0069] The water reducing rate of the above polycarboxylate high-performance water reducing agent is 28%;

[0070] B. Mold cleaning and placement

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com