Bituminous pavement local repairing structure and repairing method

An asphalt pavement, local repair technology, applied in road repair, roads, roads, etc., can solve serious damage and vehicles have to pass through the damage point, large color difference between cement pavement and asphalt pavement, and cast-in-place cement pavement maintenance time is long, etc. problems, to achieve the effect of saving repair and subsequent maintenance costs, saving repair costs, durability and overall enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

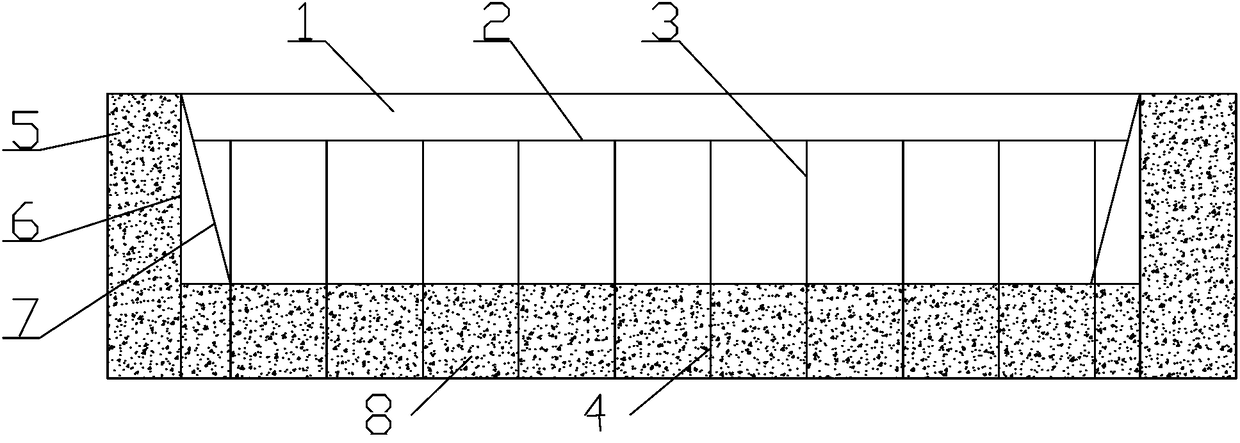

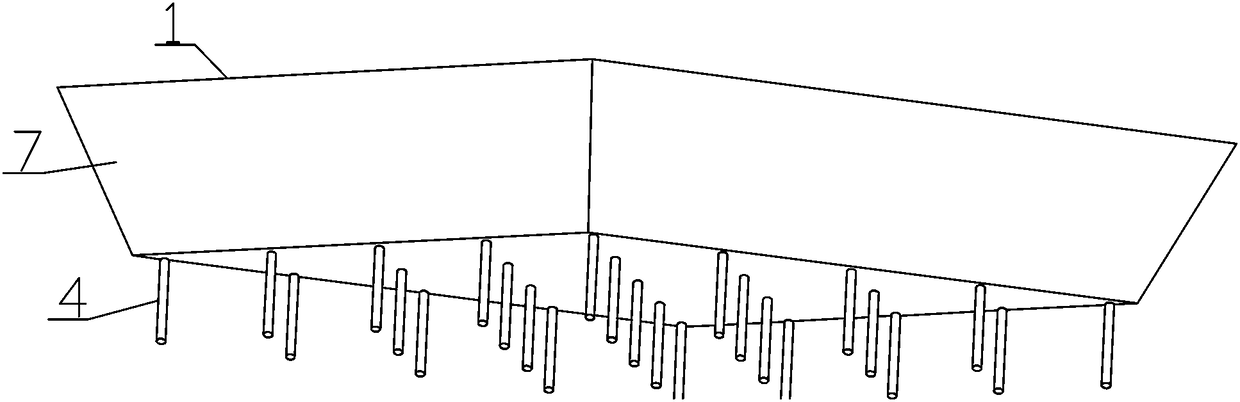

[0037] Such as Figure 1-2 As shown, the local repair structure of asphalt pavement includes a prefabricated module 1, the prefabricated module 1 adopts a wedge-shaped body, and its four sides are uniformly changing slope surfaces 7, and the described prefabricated module 1 is formed by pouring concrete. The inside of 1 is provided with a distribution rib structure 2 at a certain distance near the top surface, and each intersection position of the distribution rib structure 2 is provided with a vertically downward insertion rib 3, and the top of the insertion rib 3 is connected with the distribution rib The nodes connected to the structure 2 are bent downwards, and the extension section 4 at the bottom of the prefabricated module 1 is inserted into the cushion 8 of the subgrade 6, and the embedded prefabricated module 1 and the cushion 8 are jointly stressed. By adopting the above-mentioned repairing structure, it can be used for rapid repairing construction of asphalt pavemen...

Embodiment 2

[0044] The method for repairing the local repair structure of the asphalt pavement described in any item, it comprises the following steps:

[0045] Step1: Survey and measurement of damaged asphalt pavement: survey and measure the damaged asphalt pavement, measure the size of the damaged part, and then take photos and samples of the original pavement;

[0046] Step2: Selection of carbon black powder content: according to the black degree of the existing pavement sampled in Step1, select the appropriate carbon black powder addition amount;

[0047] Step3: Prefabrication of steel fiber black prefabricated module 1: According to the relevant data obtained in Step1 and Step2, and according to the measured size of the damaged part, select the matching module formwork, carry out mix ratio design, calculation of steel fiber consumption, installation formwork, binding Distribute and insert reinforcement, pour concrete, maintain and remove formwork, and then obtain prefabricated modules;...

Embodiment 3

[0058] In this embodiment, the following steps are included:

[0059] Step1: Investigation and measurement of damaged asphalt pavement: including taking pictures of the original pavement color and sampling, and measuring the size of the damaged part;

[0060] Step2: Selection of carbon black powder content: According to the black degree of the existing road surface, the mixing ratio test of the carbon black powder dosage is carried out separately. The carbon black powder dosage range is 0.1%-2%, and different carbon black powder blending When measuring, the brown degree of the concrete is made into a standard color comparison card, and finally the appropriate amount of carbon black powder is selected according to the sampling data of the road surface to be reinforced and replaced.

[0061] Step 3: Prefabrication of steel fiber black concrete modules: According to the relevant data obtained in steps 1 and 2, and according to the measured size of the damaged part, select the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com