Construction method for anti-radon engineering

A construction method and engineering technology, applied to floors, coverings/linings, buildings, etc., to achieve the effects of improving project quality, simplifying leveling, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

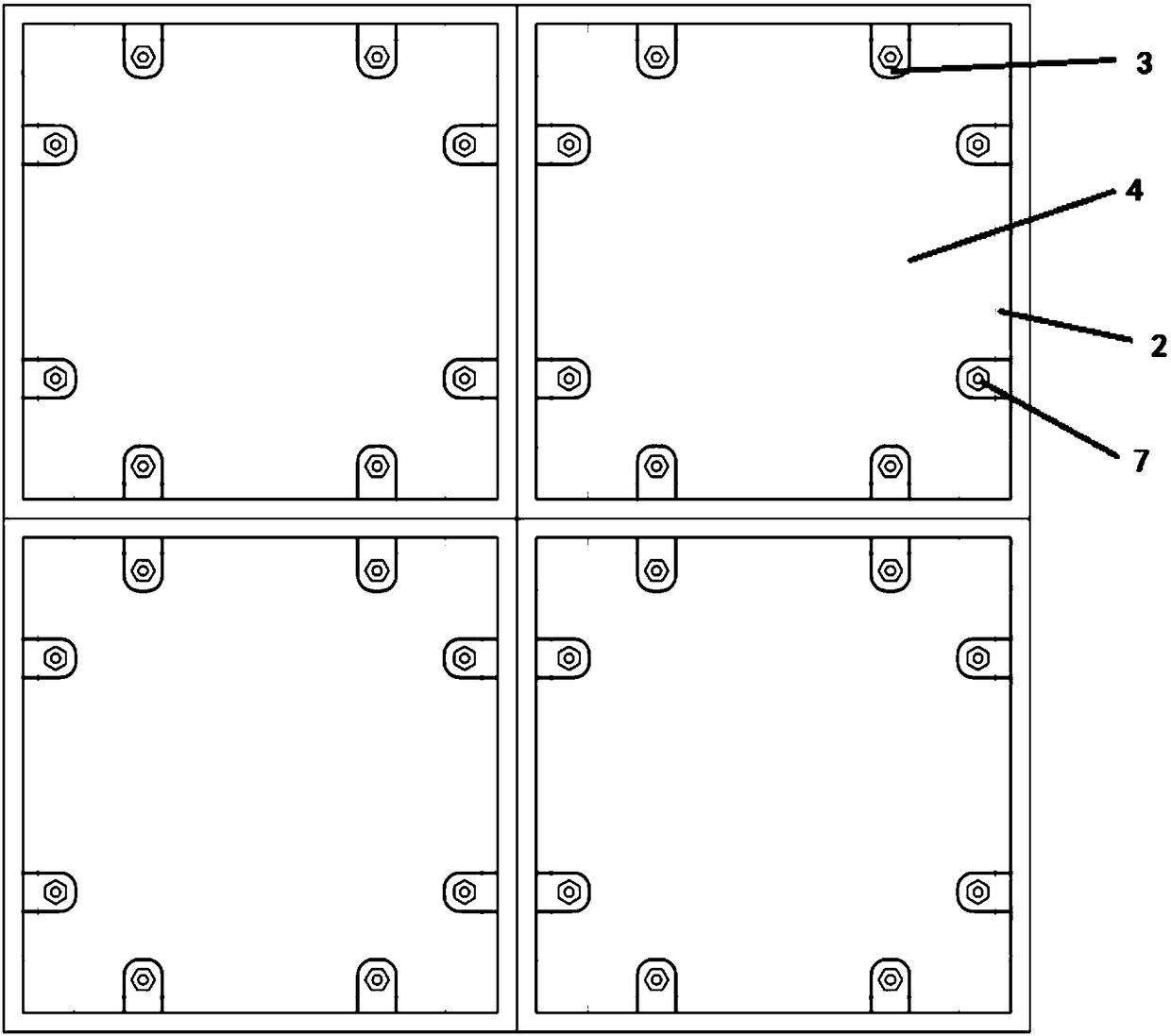

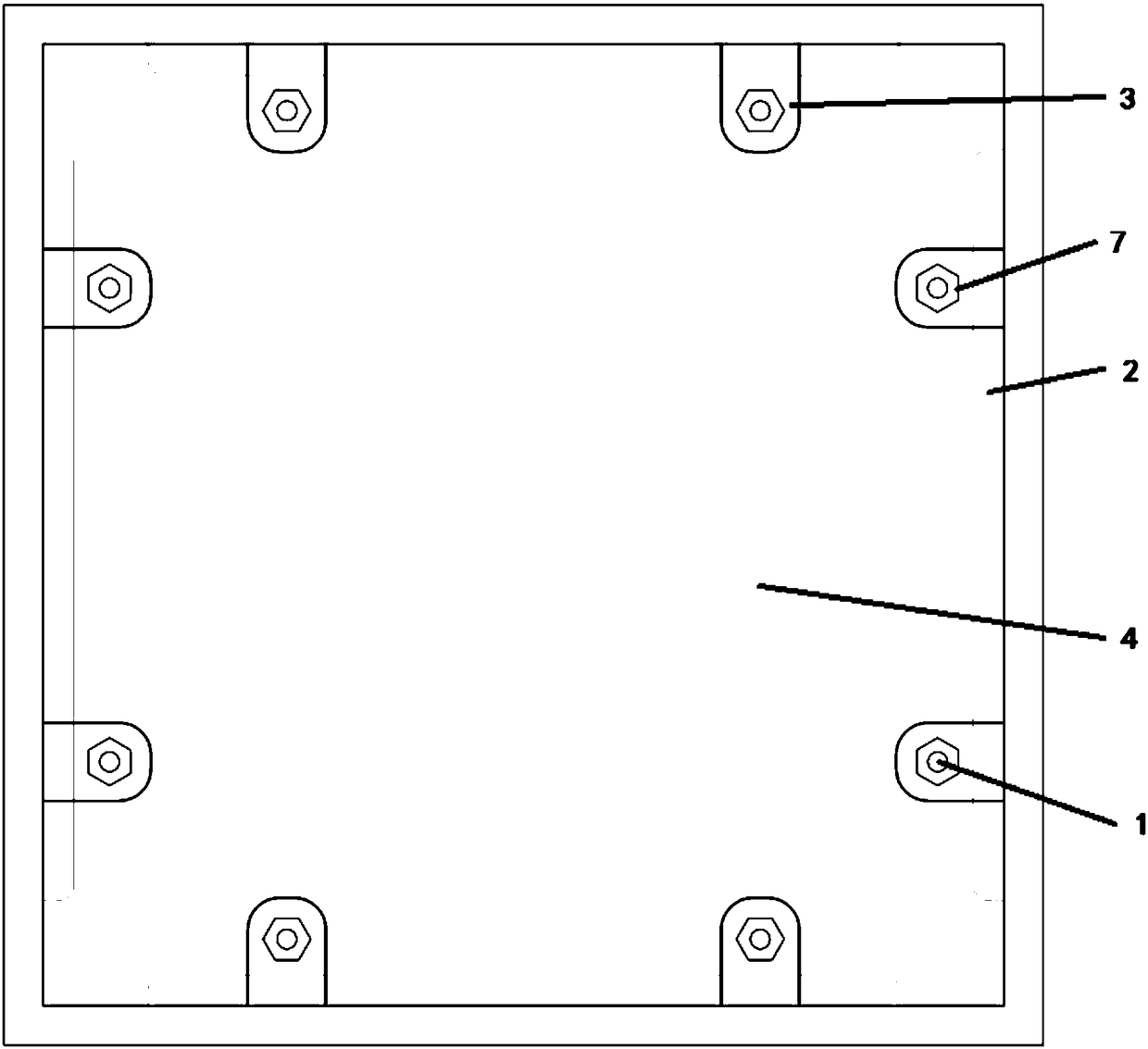

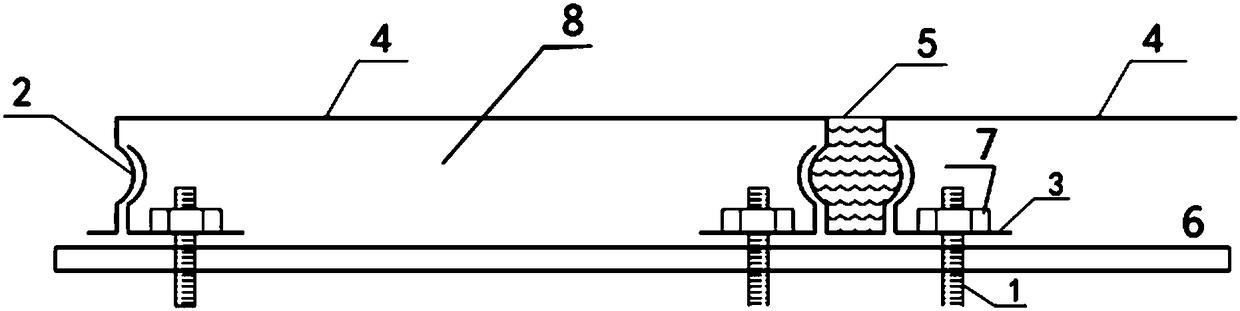

[0059] A construction method for radon prevention engineering, comprising the following steps:

[0060] Install the anchor bolt 1 on the hole wall or the wall surface, install the buckle bracket 3 on the anchor bolt 1, then fix the buckle bracket 3 on the anchor bolt 1 with the nut 7, and fix the coating plate 4 on the buckle The top of the bracket 3; the coating boards 4 are bonded and sealed with glue 5. The bottom of the coating plate 4 is provided with a groove 8, and the side of the coating plate 4 is provided with a positioning indentation 2 corresponding to the buckle bracket 3, and the buckle bracket 3 is arranged in the groove 8 Inside, the coating plate 4 is clamped on the buckle bracket 3 through the positioning indentation 2 and the groove 8 . Glue 5 is used to bond and seal the coated plate 4 at the positioning dent 2 .

[0061] Wherein, coated plate 4 is prepared by the following method:

[0062] Step 1. Weigh the following components according to mass percent...

Embodiment 2

[0073] A construction method for radon prevention engineering, comprising the following steps:

[0074] Fix the metal frame 6 on the hole wall or the wall, then install the anchor bolt 1 on the metal frame 6, install the buckle bracket 3 on the anchor bolt 1, and then use the nut 7 to fix the buckle bracket 3 on the anchor bolt 1, apply the paint The laminates 4 are fixed on the buckle bracket 3 in a clamping manner; the coating plates 4 are bonded and sealed with glue 5 . The bottom of the coating plate 4 is provided with a groove 8, and the side of the coating plate 4 is provided with a positioning indentation 2 corresponding to the buckle bracket 3, and the buckle bracket 3 is arranged in the groove 8 Inside, the coating plate 4 is clamped on the buckle bracket 3 through the positioning indentation 2 and the groove 8 . Glue 5 is used to bond and seal the coated plate 4 at the positioning dent 2 .

[0075] Wherein, coated plate 4 is prepared by the following method:

[00...

Embodiment 3

[0087] A construction method for radon prevention engineering, comprising the following steps:

[0088] Fix the metal frame 6 on the hole wall or the wall, then install the anchor bolt 1 on the metal frame 6, install the buckle bracket 3 on the anchor bolt 1, and then use the nut 7 to fix the buckle bracket 3 on the anchor bolt 1, apply the paint The laminates 4 are fixed on the buckle bracket 3 in a clamping manner; the coating plates 4 are bonded and sealed with glue 5 . The bottom of the coating plate 4 is provided with a groove 8, and the side of the coating plate 4 is provided with a positioning indentation 2 corresponding to the buckle bracket 3, and the buckle bracket 3 is arranged in the groove 8 Inside, the coating plate 4 is clamped on the buckle bracket 3 through the positioning indentation 2 and the groove 8 . Glue 5 is used to bond and seal the coated plate 4 at the positioning dent 2 .

[0089] Wherein, coated plate 4 is prepared by the following method:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Lc50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com