Synchronous grouting device and method for downslope-section tunneling of water-rich stratum shield

A technology of synchronous grouting and water-rich stratum, applied in underground chambers, shaft equipment, earthwork drilling and mining, etc., can solve the problems of poor fluidity, low early strength and late strength, water loss, etc., and achieve short solidification time and good Fluidity, effect of preventing pipe clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

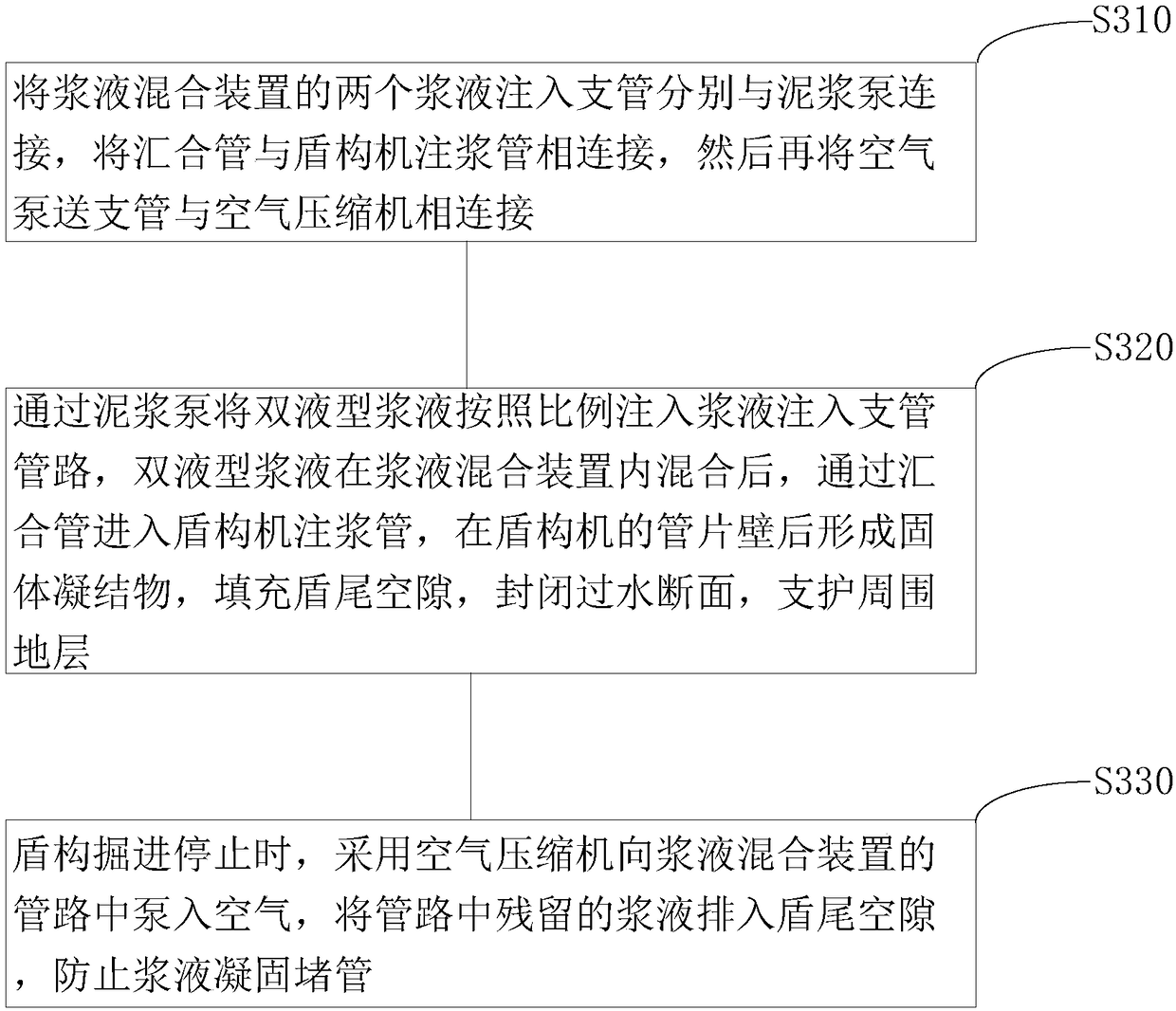

[0046] The embodiment of the present invention provides a synchronous grouting device and method for excavation in the downhill section of the shield machine in the water-rich stratum. The grout material is configured to enter the grout mixing device through two mud pumps, and enter the segment of the shield machine after being fully mixed. A further chemical reaction occurs behind the tunnel wall to form a solid condensate with a certain strength, which can effectively close the water passage behind the tunnel wall and solve the problem of water inrush and gushing in the tunnel tunneling construction of the downhill section of the shield in the water-rich stratum.

[0047] An aspect of the embodiments of the present invention provides a synchronous grouting device for tunneling downhill sections of shield tunneling in water-rich formations.

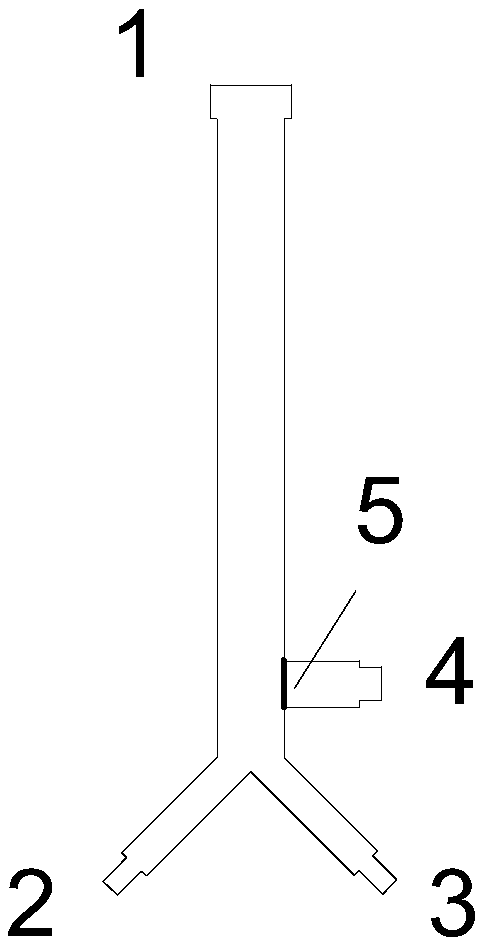

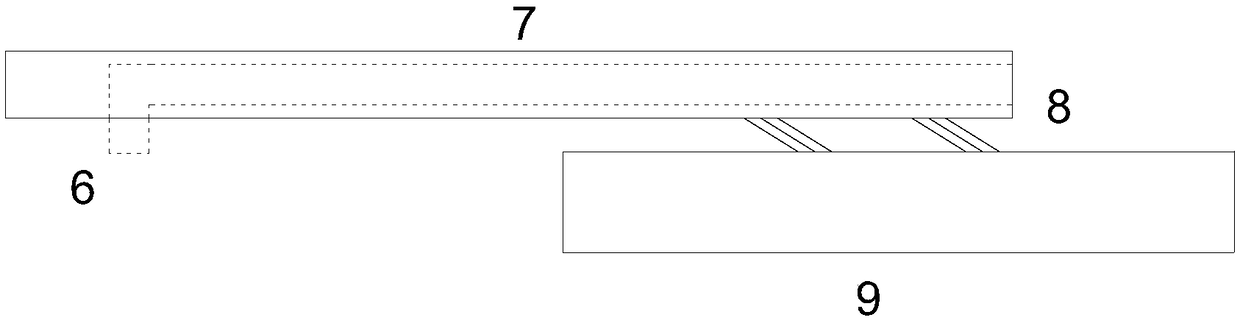

[0048] A schematic diagram of a synchronous grouting device used for excavation in the downhill section of shield tunneling in water-ric...

Embodiment 2

[0082] This embodiment provides a synchronous grouting device and method for excavation in the downhill section of shield tunneling in water-rich strata. By adopting the double-fluid synchronous grouting method for shield tunneling, the grouting time after grouting is short and the strength is high, which can effectively Close the water path behind the tunnel wall to solve the problem of water gushing in the downhill section of the shield in the water-rich stratum.

[0083] The technical scheme that the embodiment of the present invention adopts is as follows:

[0084] The utility model relates to a synchronous grouting device for excavation of shield tunneling in the downhill section of the water-rich formation, which is composed of a grout mixing device and materials. The slurry material enters the slurry mixing device through two mud pumps, and after being fully mixed, it enters the segment wall and undergoes a further chemical reaction to form a solid condensate with a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com