Micro-nano optical fiber EFPI sensor F-P cavity manufacturing device and method

A micro-nano optical fiber and sensor technology, applied in the direction of converting sensor output, using optical devices to transmit sensing components, measuring devices, etc., can solve the problems of increasing thermal expansion stress damage, affecting structural continuity, and not being able to withstand high temperatures. point, real-time monitoring, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

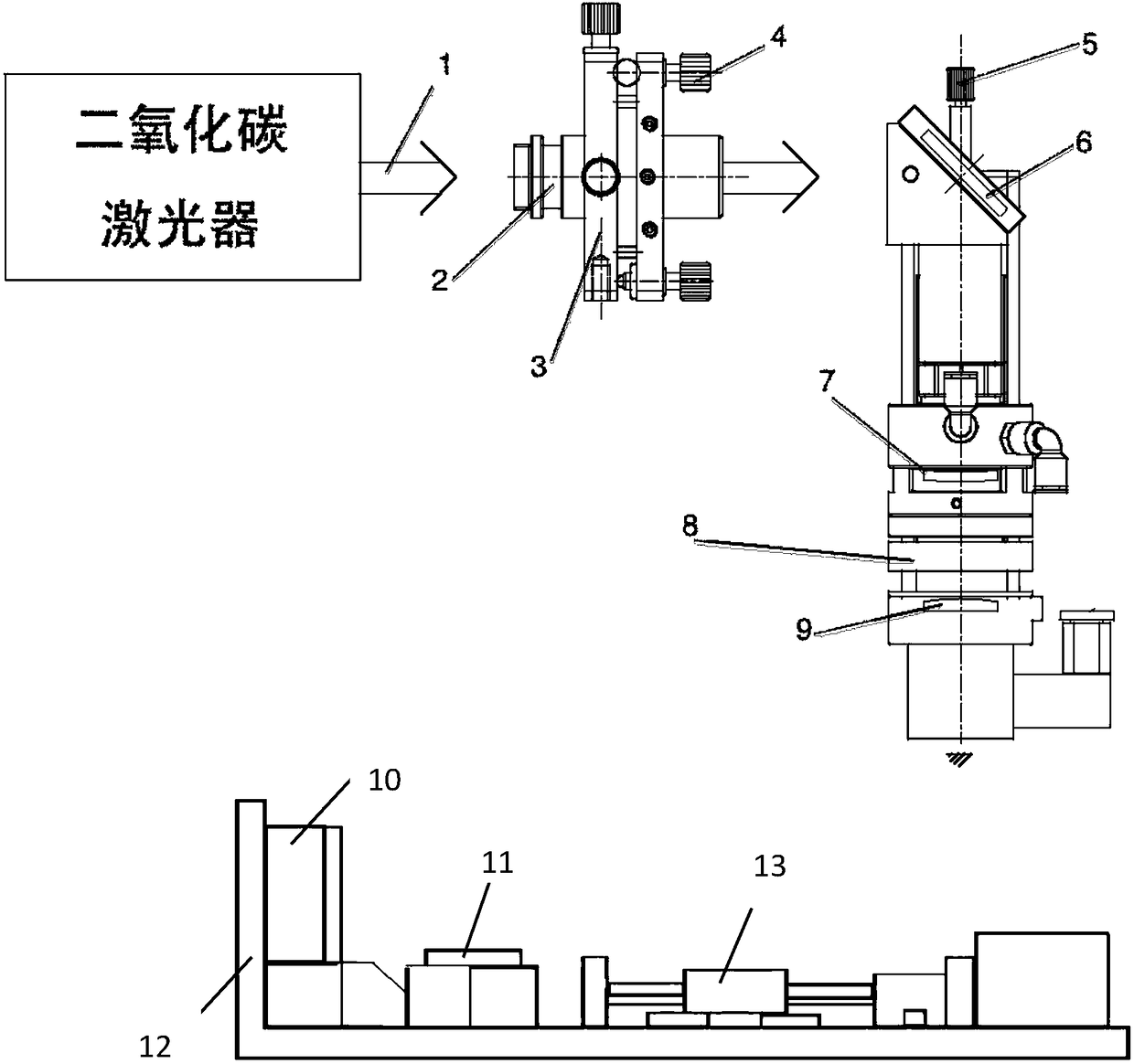

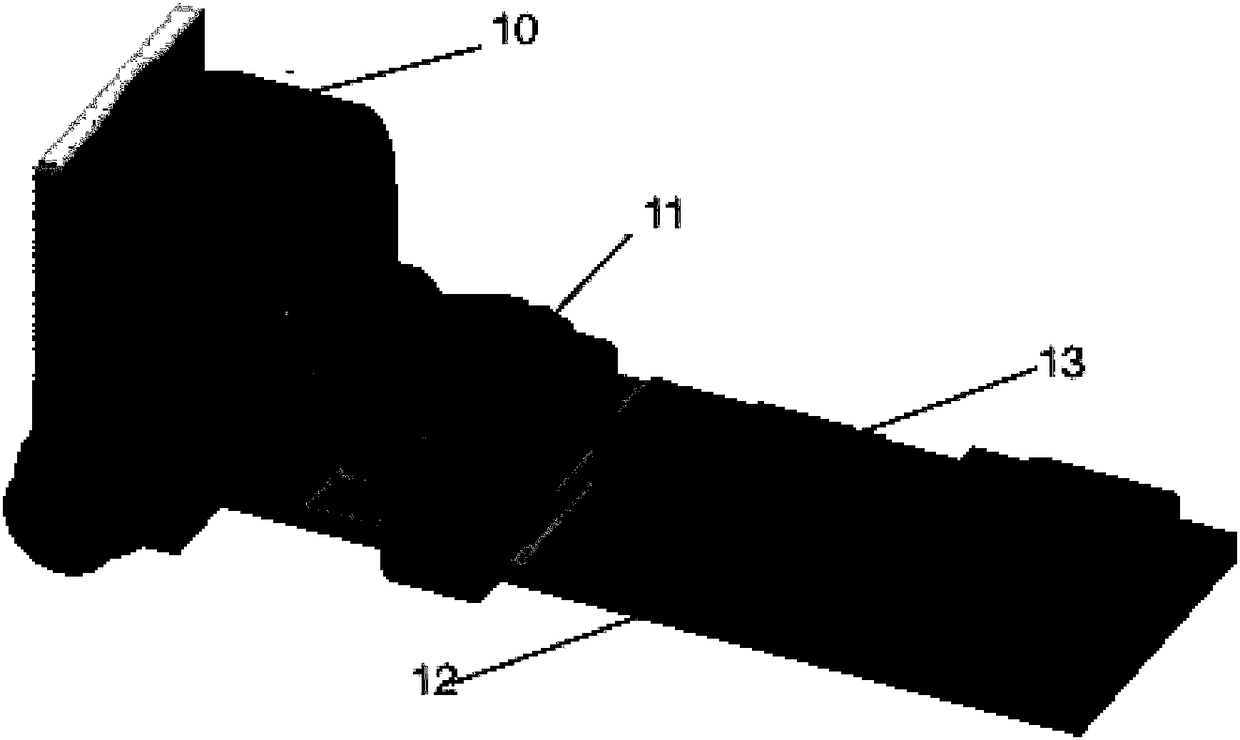

[0027] attached figure 1 Schematic diagram of the device structure for a micro-nano optical fiber EFPI sensor F-P cavity, such as figure 1 As shown, the device includes: a laser beam expansion collimation focusing optical path and a sensor manufacturing platform,

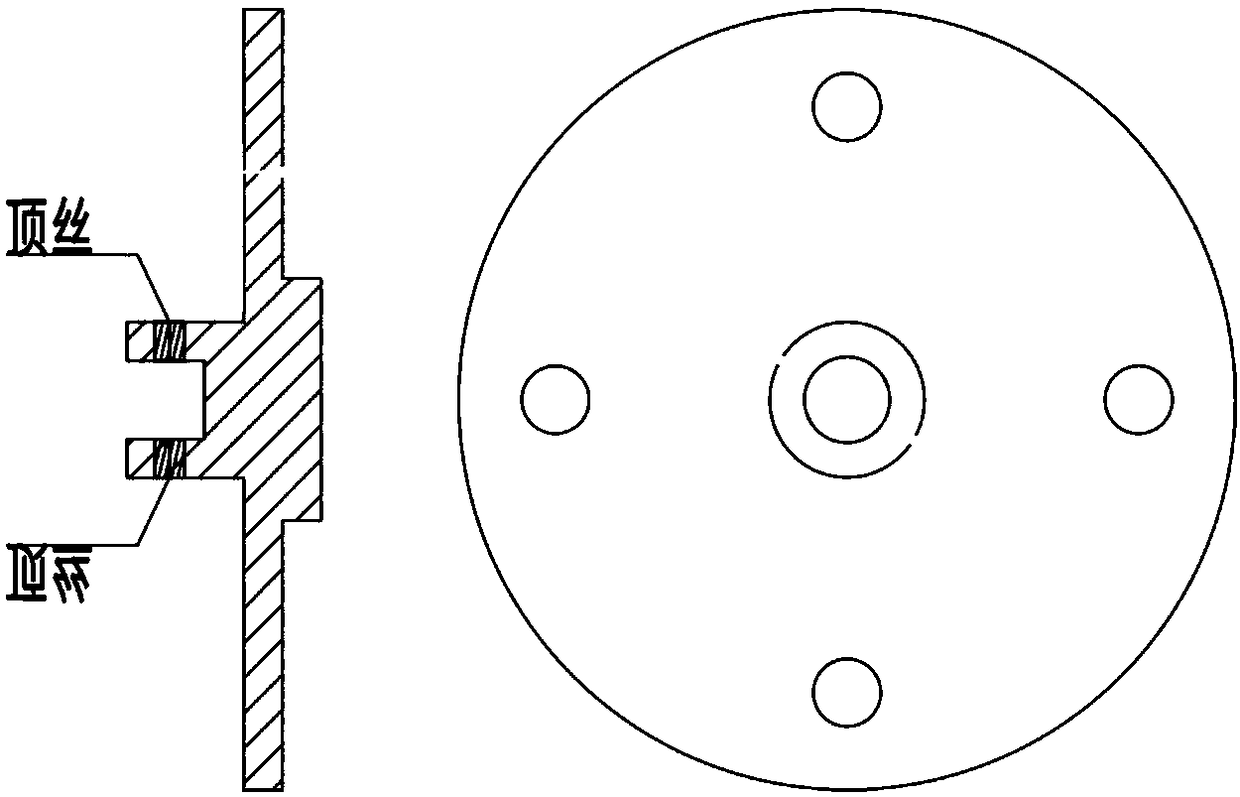

[0028] The laser beam expansion, collimation and focusing optical path is composed of three parts. The first part is a carbon dioxide laser 1, which is used as a welding laser heat source; The beam expander and collimator mirror 2 is located at the front end of the beam expander collimator barrel 3, and the position and angle of the laser beam incident on the reflector 6 are adjusted through the four jackscrews 4 on the beam expander collimator barrel 3 The third part includes a fine-tuning mechanism 5, a mirror 6, a focusing lens 7, a mirror barrel 8, and a focusing lens 9 connected in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Divergence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com