High-efficiency low-cost micro-cavity coupling system and preparing method thereof

A coupling system, low-cost technology, applied in the field of microcavity coupling system, can solve problems such as low efficiency, and achieve the effect of reducing cost and high coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

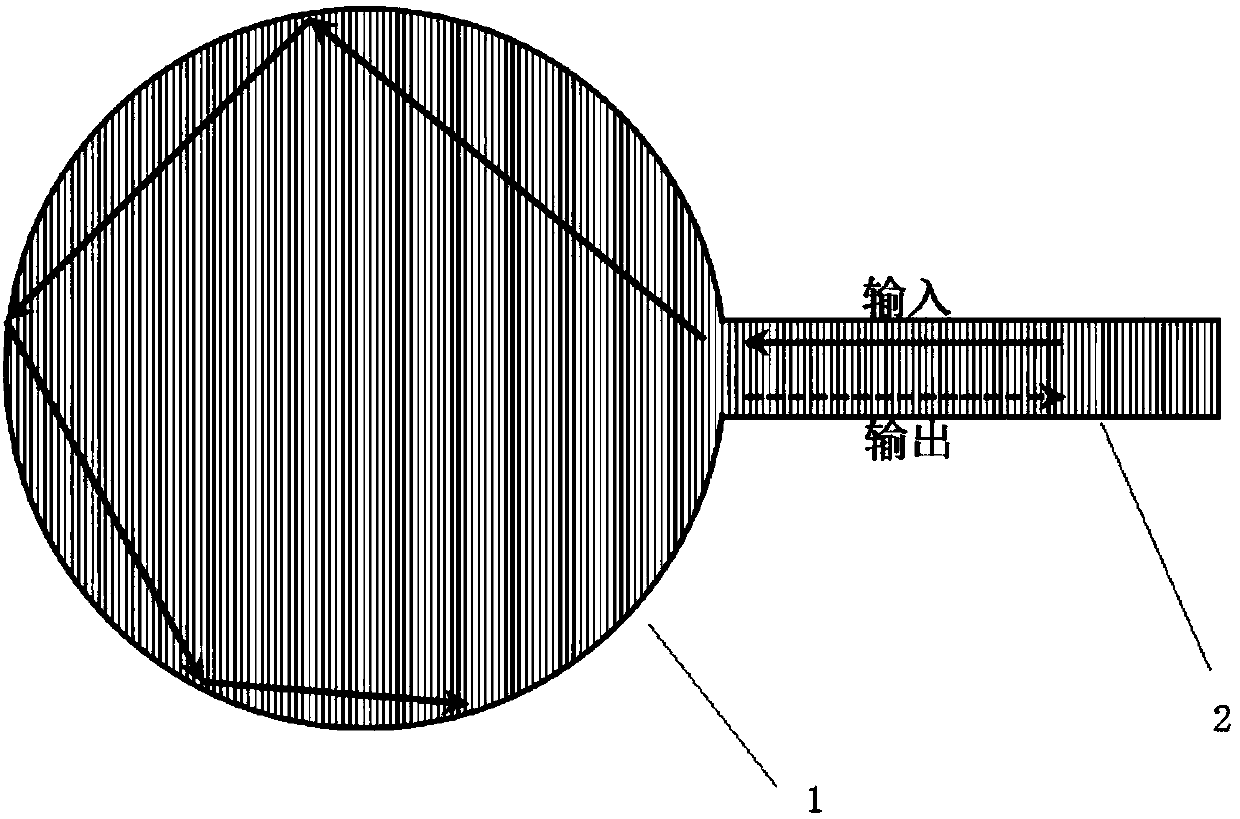

[0021] Such as figure 1 As shown, a high-efficiency, low-cost microcavity coupling system mainly consists of two parts: waveguide 2 and microcavity 1. Different from the traditional evanescent wave coupling method, in this system, the waveguide 2 is directly connected to the microcavity 1, and after the optical signal is input into the connection waveguide 2, it directly enters the microcavity 1 to excite a resonant mode, so there is no need to consider the waveguide Phase-matched with microcavity 1. In actual preparation, since the size of waveguide 2 and microcavity 1 is often above 500nm, and the distance between waveguide 2 and microcavity 1 does not need to be considered, this structure can be prepared by traditional photolithography method, which greatly reduces the preparation cost and is convenient. Large-scale batch production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com