Photoelectric heating self-blasting drying device with heat storage function

A blast drying and photoelectric technology, applied in the direction of heating device, drying gas arrangement, static material dryer, etc., can solve the problems of unsatisfactory drying effect, poor integrity, low drying temperature, etc., and achieve increased retention and replacement Heat time, enhanced heat transfer effect, faster heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

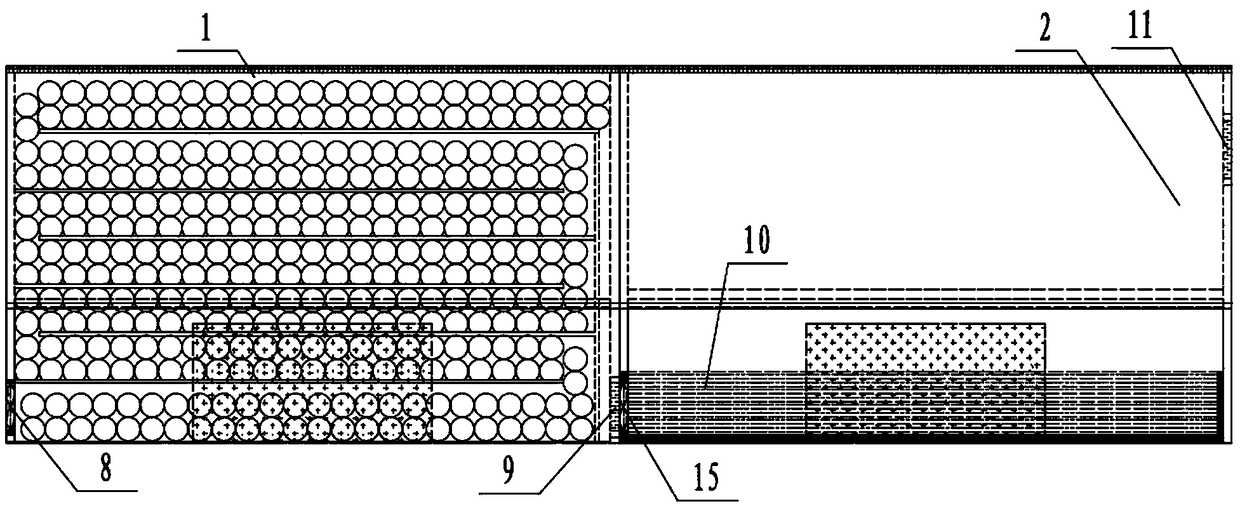

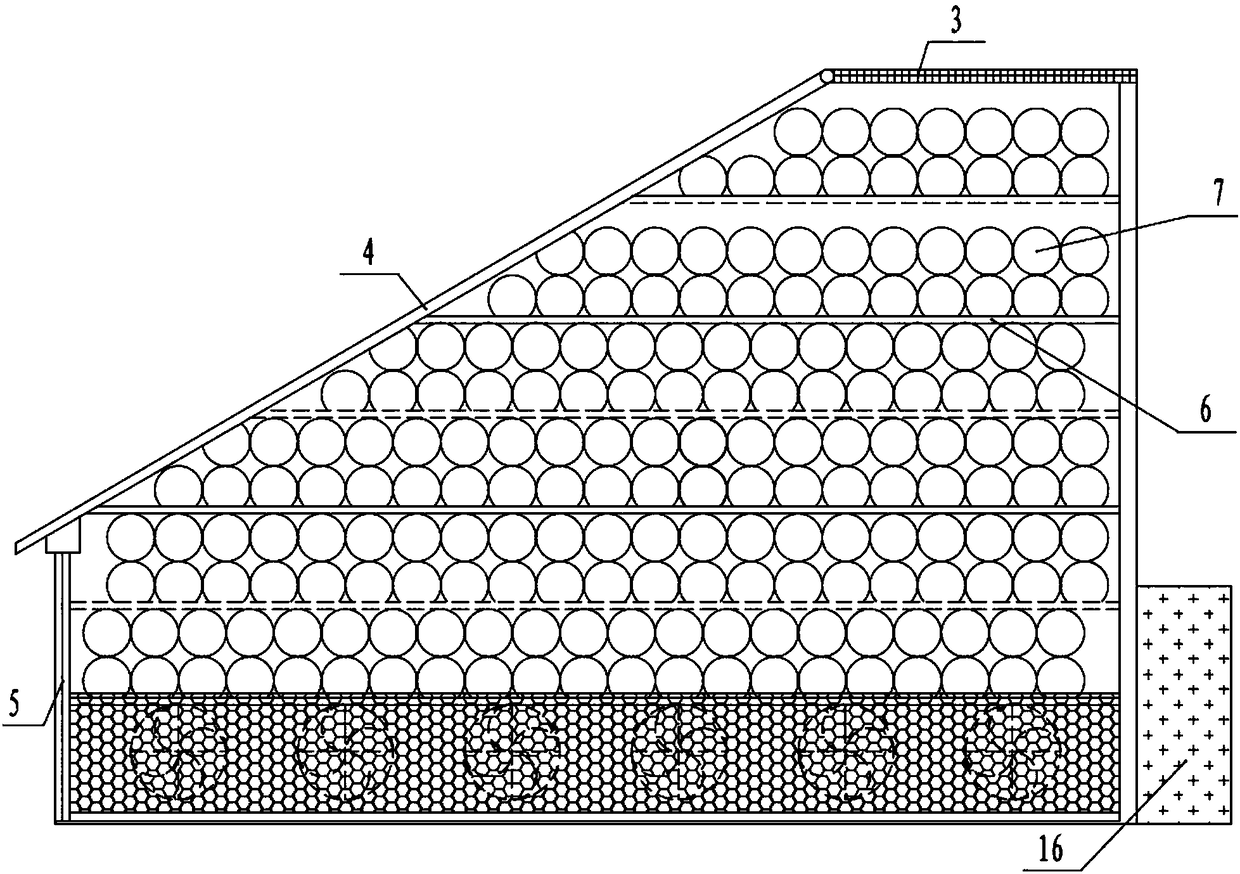

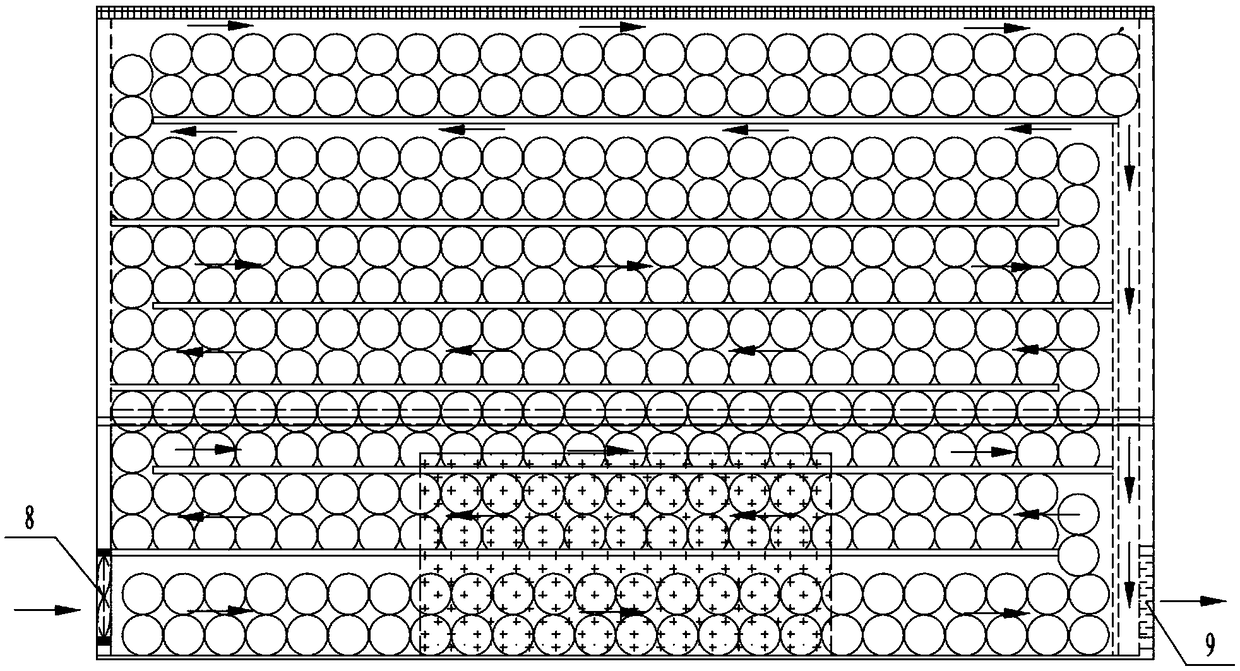

[0028] Embodiment 1: as Figure 1-Figure 8 As shown, a photoelectric thermal self-blowing drying device with heat storage function includes a heat storage device 1 and a drier 2, the heat storage device 1 is a box structure, and the top rear end is provided with a solar cell panel-3, and the solar cell The front end of the plate 3 is hinged with an inclined glass cover plate 4, and the other end of the glass cover plate 4 is fixedly connected with a vertical support plate 5. The support plate 5 is located at the front side of the heat storage device 1. A plurality of transparent partitions 6 are provided, and the front and rear sides of the transparent partitions 6 are fixed and sealed. The bottom air inlet of the shaped communication structure is provided with a fan unit 8, and the top air outlet is connected to the hot air outlet 9 at the bottom through the vertical channel on the right side of the heat storage device 1, and the hot air outlet 9 is connected to the air inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com