Automatic early warning device and method of coal mining machine transient detection

An automatic early warning, shearer technology, applied in the direction of measuring devices, alarms, computer control, etc., can solve the problems of poor accuracy, easy damage, slow speed, etc., and achieve the effect of ensuring accuracy, high precision and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

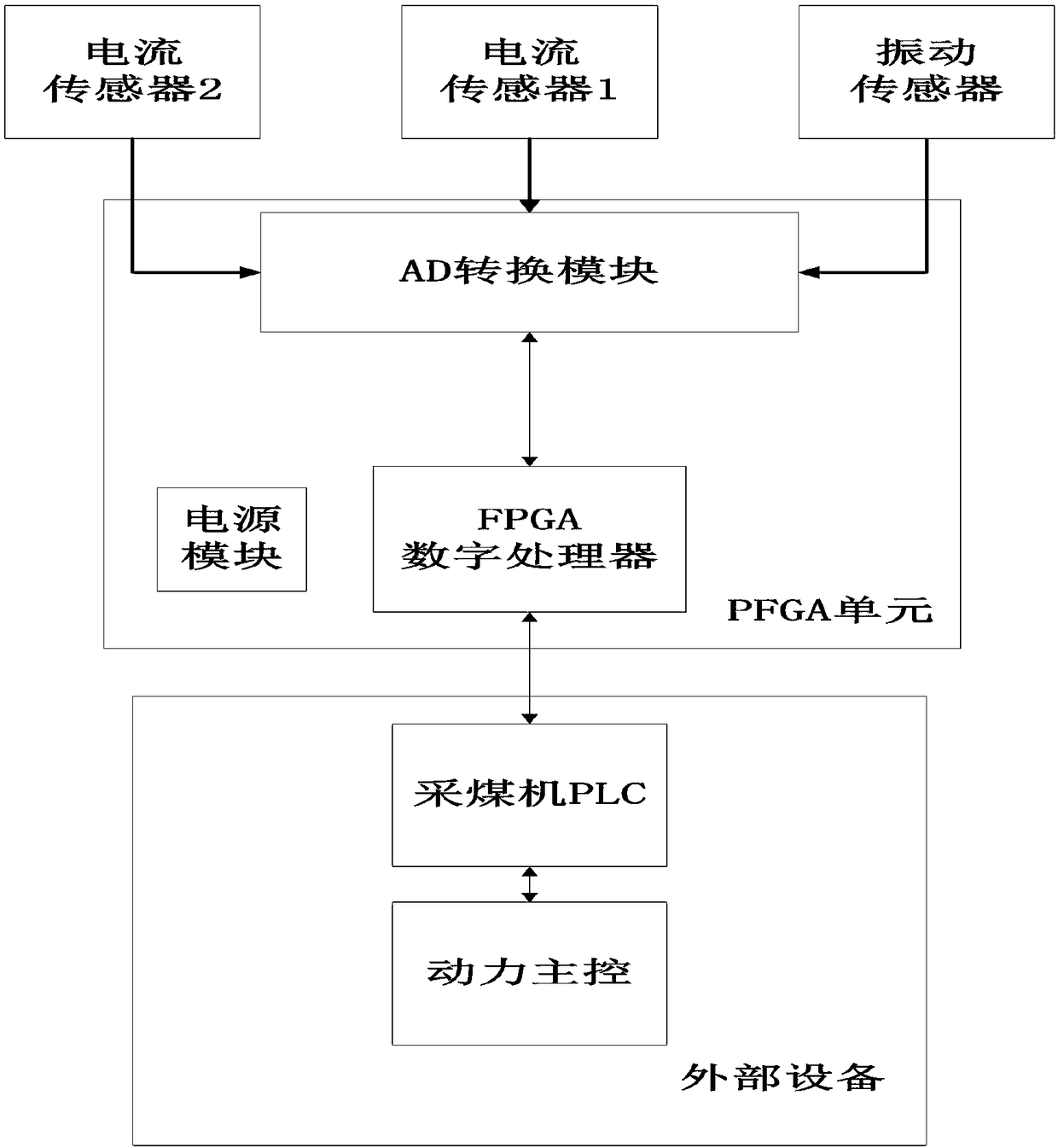

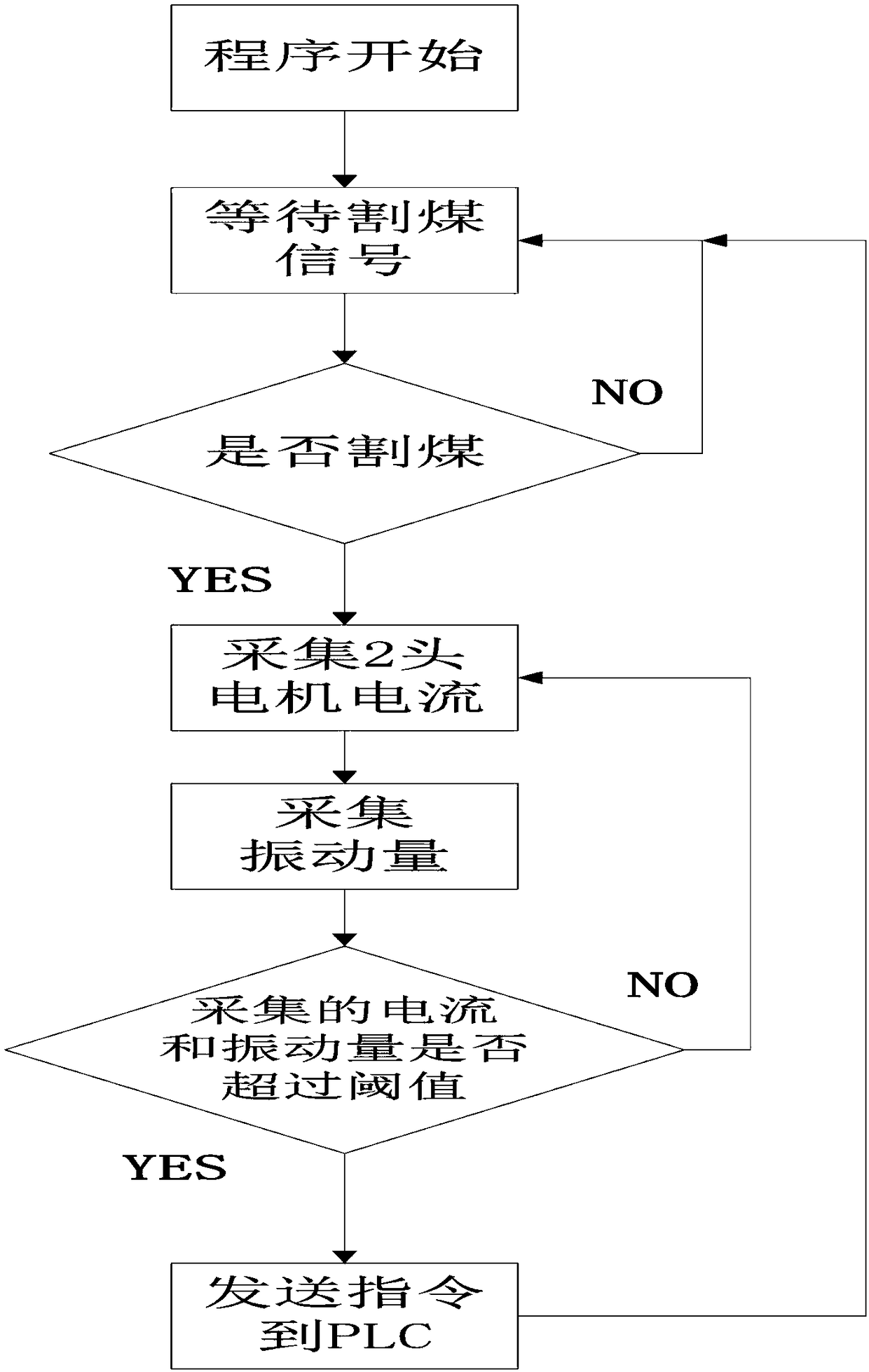

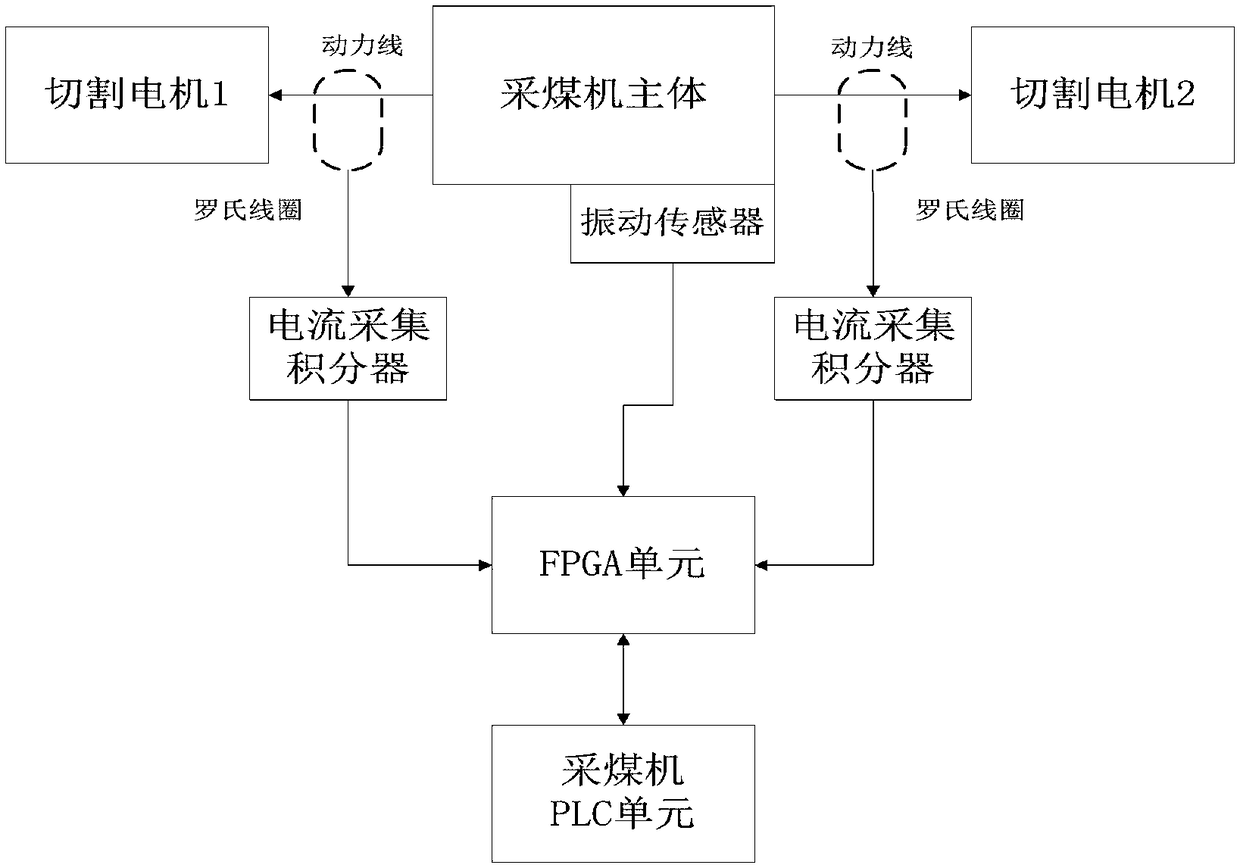

[0017] An automatic warning device and method for transient detection of a coal shearer, comprising: a first current sensor, a second current sensor, a vibration sensor, and an FPGA unit.

[0018] The first current sensor and the second current sensor are used to sense the transient current on the working power line of the two coal machine cutting motors, and convert it into an analog voltage signal in a specific ratio.

[0019] The vibration sensor is used to sense the vibration frequency and vibration intensity of the fuselage body when the coal machine is working, and convert it into an analog voltage signal according to a specific ratio.

[0020] Described FPGA unit comprises power supply module and the AD conversion module and the FPGA digital processor that are connected with power supply module; Described power supply module is used to provide stable DC operating voltage to each module in FPGA unit; Described AD conversion module It is used to collect the analog voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com