Detection method of hydride and special device

A hydride, atomizing gas technology, applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc., can solve the problems of high element ionization, low element content, low sensitivity, etc., to achieve broad application value, simplify Experimental procedure, the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

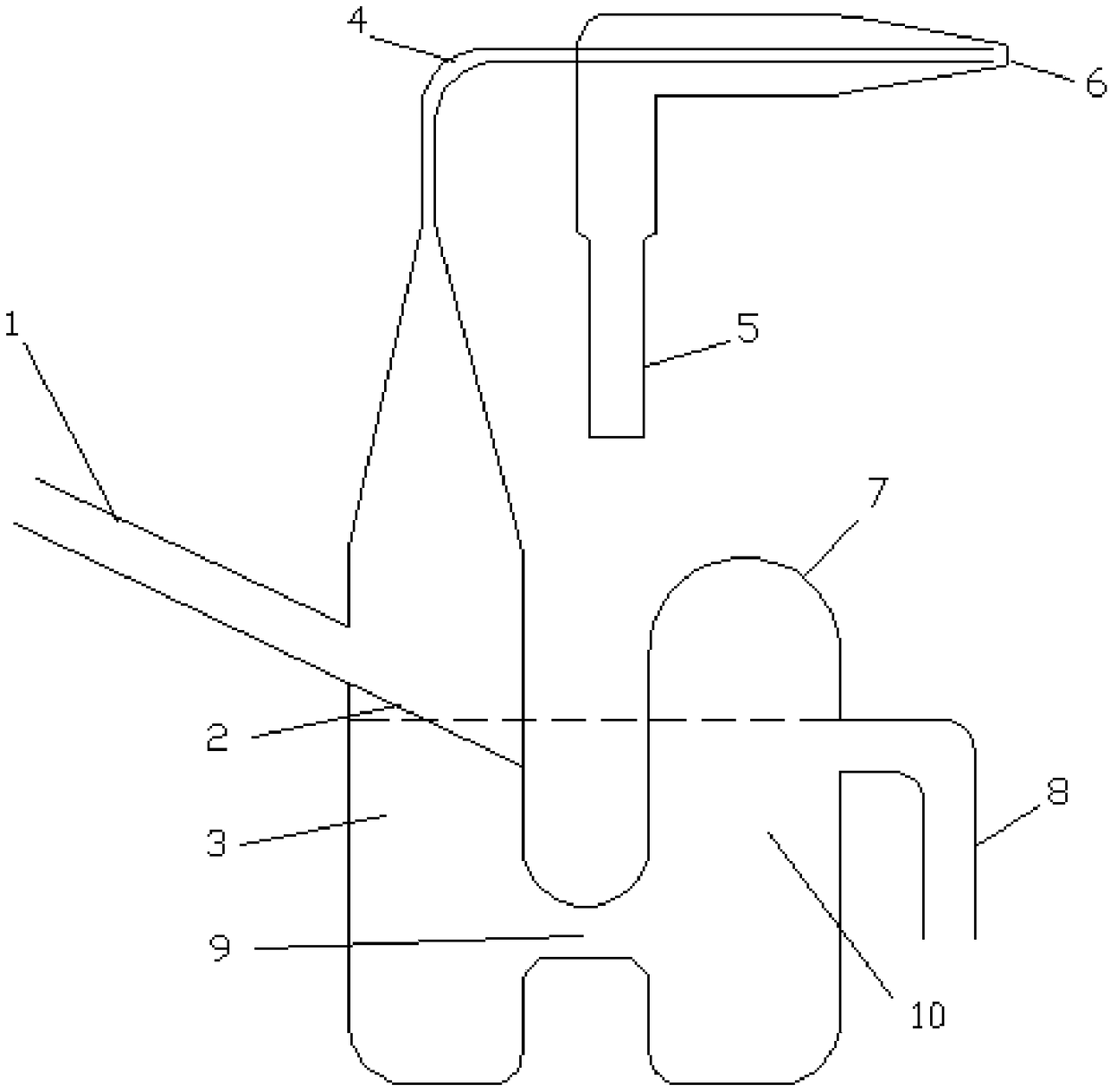

[0023] Such as figure 1 As shown, the ICP-OES hydride atomization system includes a gas-liquid sampling tube 1, a gas-liquid separation unit 3, a gas center tube 4, an atomized gas inlet tube 5, and a liquid level balance unit 10, wherein the gas-liquid separation unit 3 It communicates with the bottom of the liquid level balance unit 10, and the upper part of the gas-liquid separation unit 3 communicates with the gas-liquid sampling tube 1 and the gas central tube 4, and the end of the gas central tube 4 is accommodated at the nozzle 6 of the atomizing gas inlet tube 5 , One side of the liquid level balance unit 10 is provided with a drain port, and the drain port is connected to the drain pipe 8 .

[0024] Further, the gas-liquid separation unit 3 is provided with a draft tube 2 communicating with the gas-liquid sampling tube 1 . The draft pipe 2 is inclined downwards and has an open structure above. The reacted gas-liquid mixture flows through the gas-liquid sampling pipe...

Embodiment 2

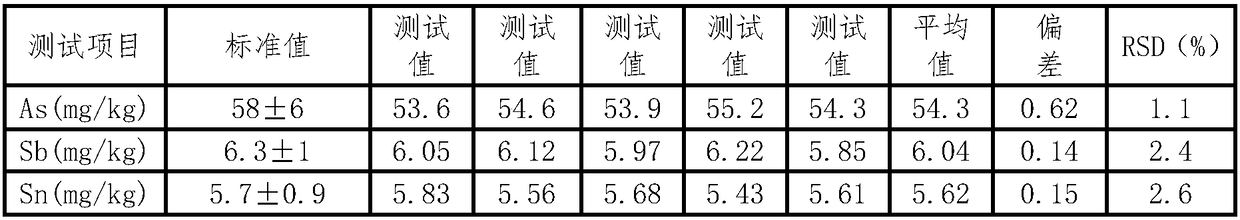

[0031] Determination of As, Sb, Sn elements in soil

[0032] 1. Accurately weigh 100mg of soil sample into a 15ml polytetrafluoroethylene liner;

[0033] 2. Add 2.5ml HF and 0.5ml HCl, pre-digest on a 150°C electric heating plate for 2 hours, open the cover to release the pressure;

[0034] 3. Seal the pre-digested sample and place it in an antiseptic high-efficiency sample dissolution tank;

[0035] 4. Digest in an anti-corrosion electric oven at 180°C for 12 hours and cool down;

[0036] 5. Take out the liner, add 1ml of HCl on a 150°C electric heating plate to catch the acid until it is completely dry;

[0037] 6. Add 1ml HCl and 2ml 18.2MΩ pure water, and digest at 150℃ for 12 hours;

[0038] 7. Cool, take out the liner, add 1ml of 10% thiourea, dilute to 5g (the dilution factor is about 50 times).

[0039] The 1% potassium borohydride introduced through the injection tube reacts with the reducing agent tube to generate hydrogen, which forms hydrides with As, Sb and Sn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com