Mold and mold manufacturing method

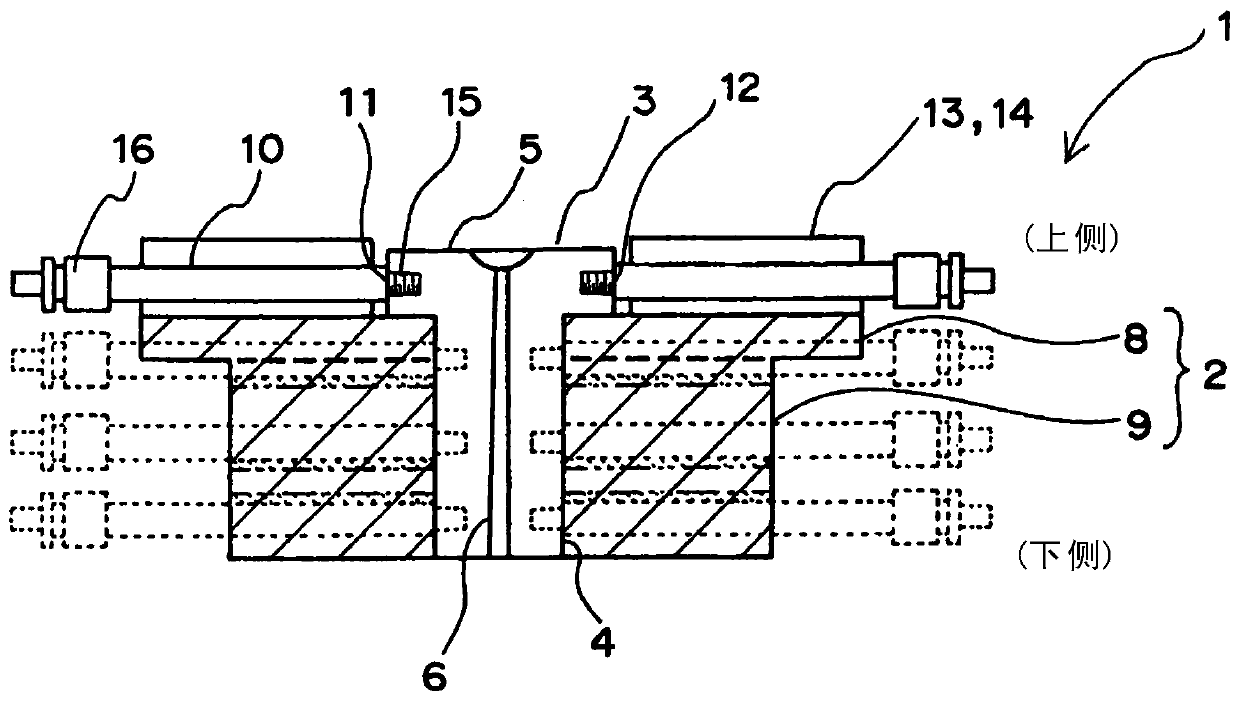

A manufacturing method and mold technology are applied in the field of injection molding molds and injection molding mold manufacturing, which can solve the problems of difficult and reliable temperature control, difficult to form water pipe paths, easy damage to O-rings, etc. The effect of shortened molding cycle and reliable temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Under the following conditions, a molded article was obtained.

[0058] Resin material: PPWW567w3952

[0059] Mould: (size) 300mm×500mm×345mm / (mass) 403kg

[0060] Forming machine: Nissei ES2000

[0061] like Figure 8A and Figure 8B As shown, according to the injection molding die 1 according to the embodiment of the present invention, the cooling time of the molten resin can be shortened from 13 s to 8 s compared with the conventional mass production die, and as a result, the entire molding cycle can be shortened by 25.7% (35s→26s).

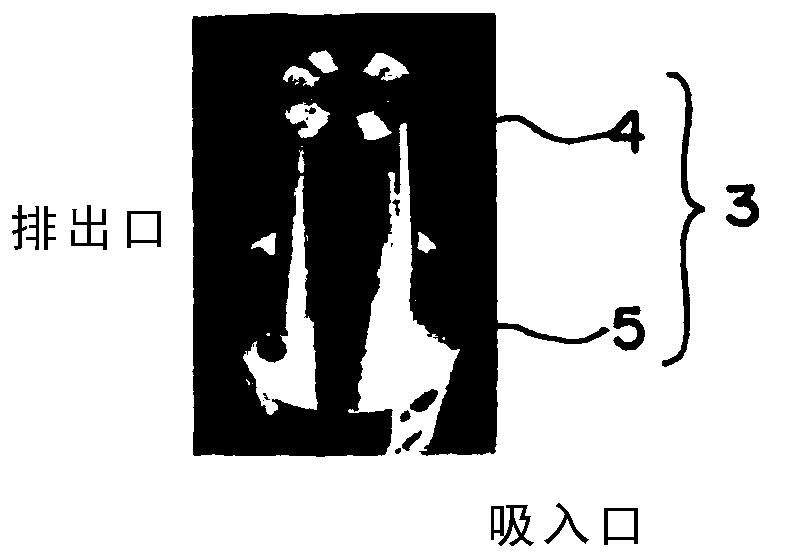

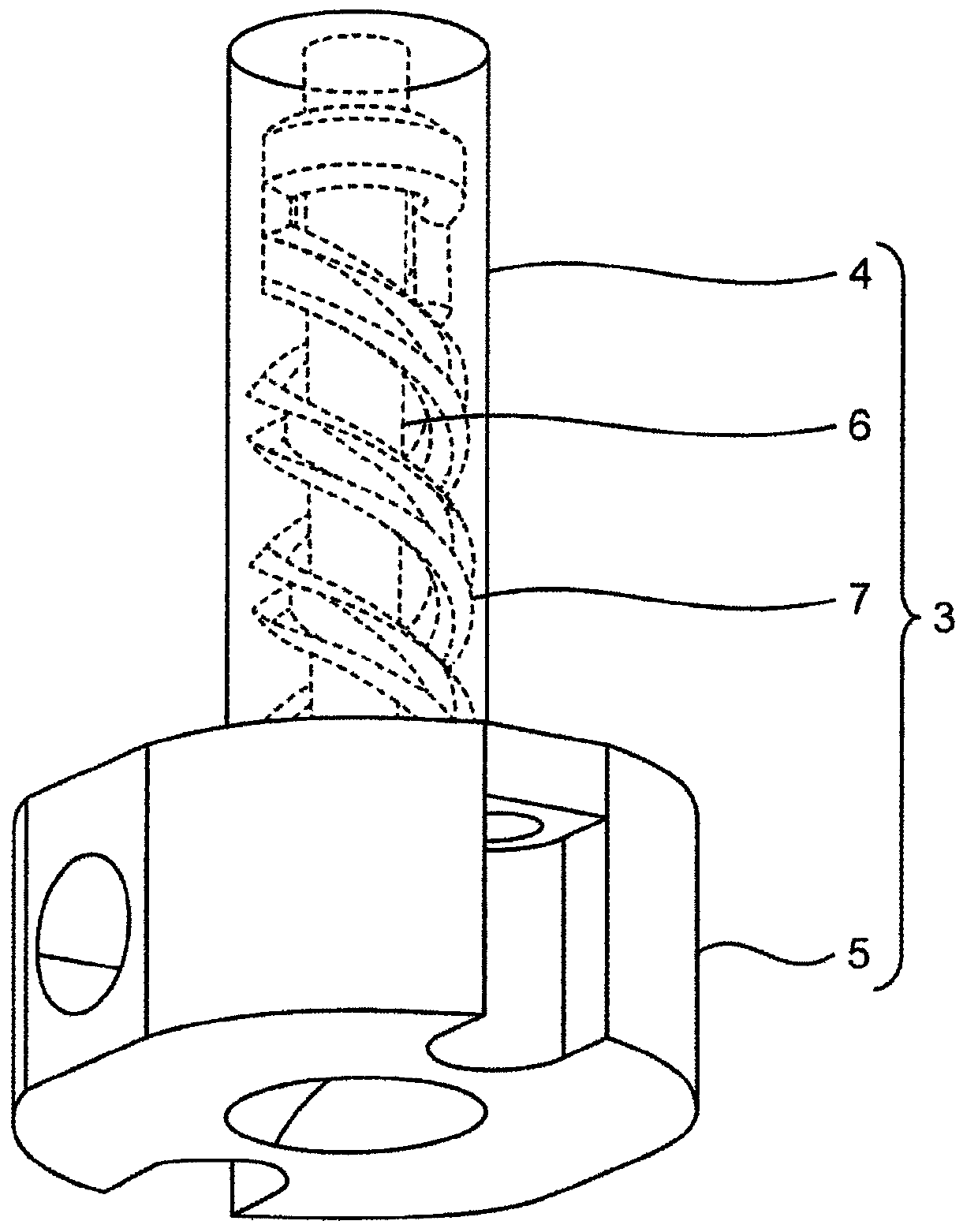

[0062] In the case of using the injection molding die 1 according to an embodiment of the present invention, as Figure 8C As shown in the photograph of , since the cooling temperature of the molten resin can be appropriately controlled and the molten resin can be sufficiently cooled, the sprue runner portion is in a good state. In contrast, in the case of using conventional mass production molds, such as Figure 8D As shown, the...

Embodiment 2

[0064] like Figure 9A and Figure 9B As shown, with the injection molding die 1 according to the embodiment of the present invention, the cooling time of the molten resin can be shortened from 39 s to 25 s compared with the conventional mass production die, and as a result, the entire molding cycle can be shortened by 30.8% (65s→45s).

[0065] When the injection molding die 1 according to the embodiment of the present invention is used, since the cooling temperature of the molten resin can be appropriately controlled to sufficiently cool the molten resin, the phenomenon of runner elongation does not occur. In addition, the temperature analysis of the runner jacket 3 between the cooling steps was carried out, such as Figure 9CAs shown, it can be seen that the temperature in the vicinity of the injection port of the sprue sleeve is sufficiently cooled as compared with other parts of the sprue sleeve. On the other hand, when a conventional mass production mold is used, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com