Blow boiling cold-concentration pool

A boiling pool and cold concentration technology, applied in evaporator accessories, evaporation, chemical instruments and methods, etc., can solve the problems of low concentration efficiency, high equipment requirements, slow flow speed, etc., to save operation and maintenance costs and equipment requirements Not high, the effect of saving equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

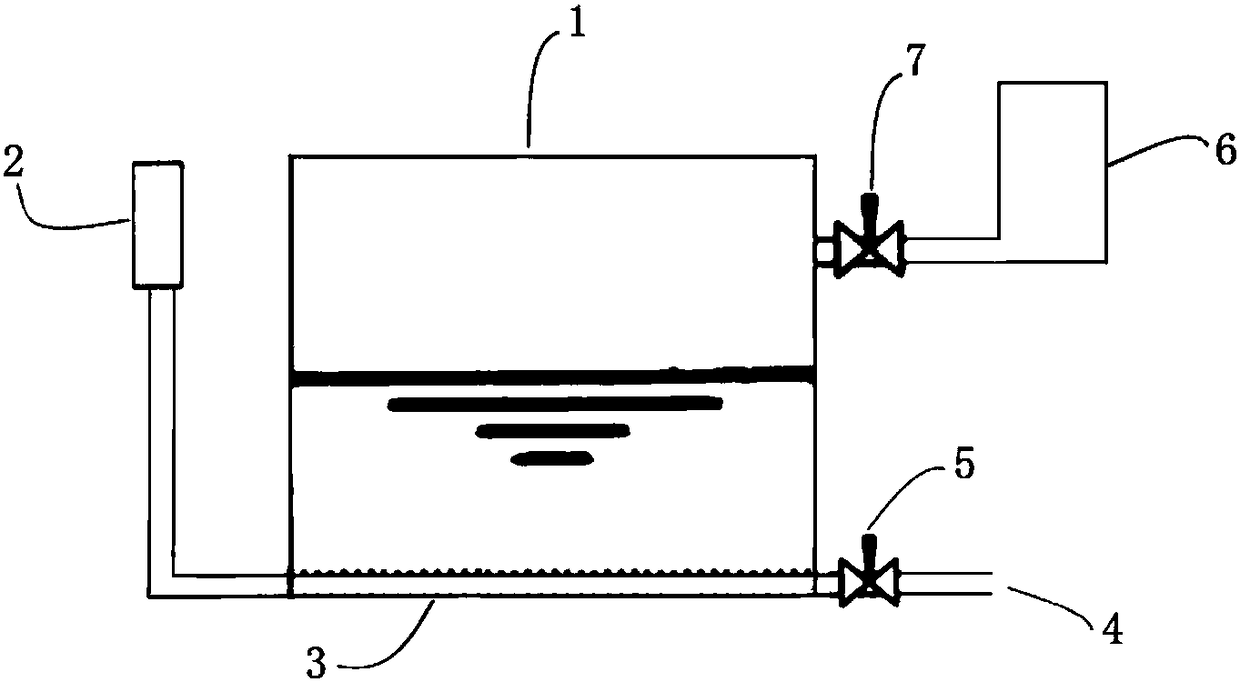

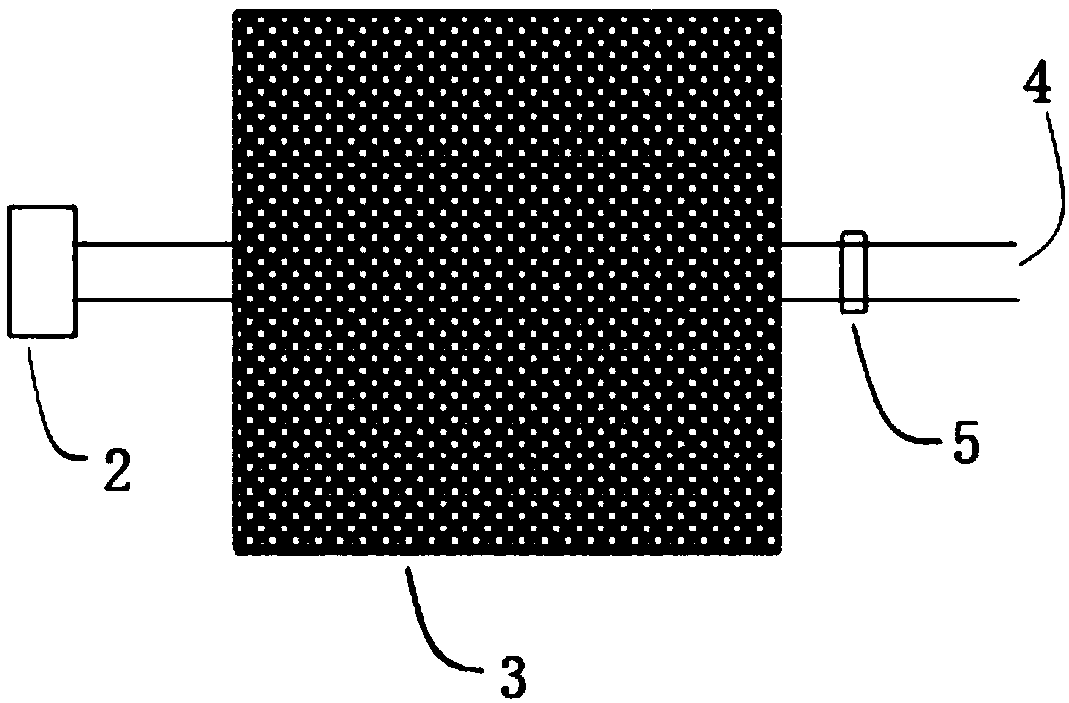

[0012] Such as figure 1 As shown, a honey blowing boiling cold concentration tank includes a boiling tank 1, a blower 2 and a hollow porous plate 3. The boiling pool 1 is a cuboid with an open upper end. The blower 2 is connected to the hollow porous plate 3 through pipelines, and the blower 2 is located above the liquid surface of honey in the boiling pool 1 . The hollow perforated plate 3 is horizontally fixed on the bottom of the boiling pool 1 . Such as figure 2 As shown, the hollow porous plate 3 is a plate-shaped cuboid with five sides closed and one side full of pores and the inside is hollow. The pores of the hollow porous plate 3 face the opening end of the boiling pool 1 .

[0013] When carrying out the cold concentration operation of honey, the honey to be concentrated is added into the boiling pool 1, and the blower 2 is turned on, and a large number of air bubbles are generated on the upper surface of the hollow porous plate 3, and the large number of air bubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com