High-efficiency formaldehyde removing spray preparation method

A formaldehyde and spray technology, applied in the field of preparation of high-efficiency formaldehyde-removing sprays, can solve the problems of high efficiency and low formaldehyde removal efficiency, and achieve the effects of high formaldehyde efficiency, high formaldehyde removal efficiency, and high formaldehyde removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

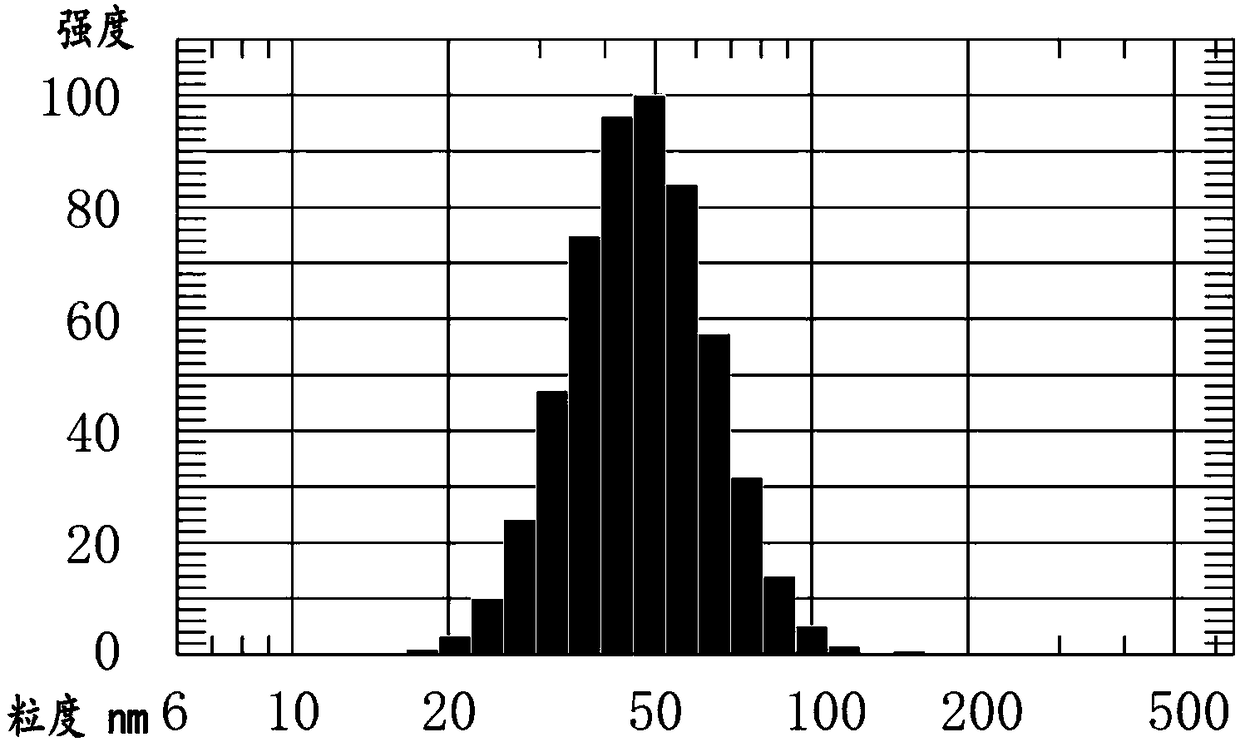

[0016] Take tin chloride, titanium tetrachloride and ethanol (the mol ratio of titanium tetrachloride and tin chloride is 1:0.1; The mol ratio of titanium tetrachloride and ethanol is 1:40), at first titanium tetrachloride Add it into ethanol, adjust the pH=2~3 by dropwise adding acetic acid, stir to make it fully dissolved; then add tin chloride to the solution, stir to make it fully dissolved. Next, raise the temperature of the solution to a certain temperature (70°C) and keep it for a period of time (1 hour), and then adjust the pH ≈ 7 by adding ammonia water dropwise to obtain a solid powder, which is centrifugally washed, dried and dried at a high temperature (800°C) ) after calcining for a certain period of time (1 hour) to obtain tin-doped nano-titanium dioxide powder. Mix the above powder, negative ion powder with a certain amount of dispersant and deionized water (the mass ratio of tin-doped nano-titanium dioxide powder, negative ion powder, dispersant and deionized w...

Embodiment 2

[0018] Take tin chloride, titanium tetrachloride and ethanol (the mol ratio of titanium tetrachloride and tin chloride is 1:0.2; The mol ratio of titanium tetrachloride and ethanol is 1:50), at first titanium tetrachloride Add it into ethanol, adjust the pH=2~3 by dropwise adding acetic acid, stir to make it fully dissolved; then add tin chloride to the solution, stir to make it fully dissolved. Next, raise the temperature of the solution to a certain temperature (80°C) and keep it for a period of time (2 hours), and then adjust the pH ≈ 7 by adding ammonia water to obtain a solid powder, which is centrifugally washed, dried and dried at a high temperature (700°C) ) after calcining for a certain period of time (3 hours) to obtain tin-doped nano-titanium dioxide powder. Mix the above powder, negative ion powder with a certain amount of dispersant and deionized water (the mass ratio of tin-doped nano-titanium dioxide powder, negative ion powder, dispersant and deionized water is...

Embodiment 3

[0020] Take tin chloride, titanium tetrachloride and ethanol (the mol ratio of titanium tetrachloride and tin chloride is 1:0.01; The mol ratio of titanium tetrachloride and ethanol is 1:60), at first titanium tetrachloride Add it into ethanol, adjust the pH=2~3 by dropwise adding acetic acid, stir to make it fully dissolved; then add tin chloride to the solution, stir to make it fully dissolved. Next, raise the temperature of the solution to a certain temperature (60°C) and maintain it for a period of time (0.5 hours), then adjust the pH ≈ 7 by adding ammonia water dropwise to obtain a solid powder, which is centrifugally washed, dried and dried at high temperature (900°C) ) after calcining for a certain period of time (0.5 hours) to obtain tin-doped nano-titanium dioxide powder. Mix the above powder, negative ion powder with a certain amount of dispersant and deionized water (the mass ratio of tin-doped nano-titanium dioxide powder, negative ion powder, dispersant and deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com