Preparation method, product and applicationof weak light photocatalyst composite formaldehyde removal spray

A low-light, aldehyde spray technology, applied in the fields of nanotechnology and fine chemicals, can solve problems such as high efficiency and low formaldehyde removal efficiency, and achieve the effects of simple preparation method, long-term effective formaldehyde removal, and improved dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

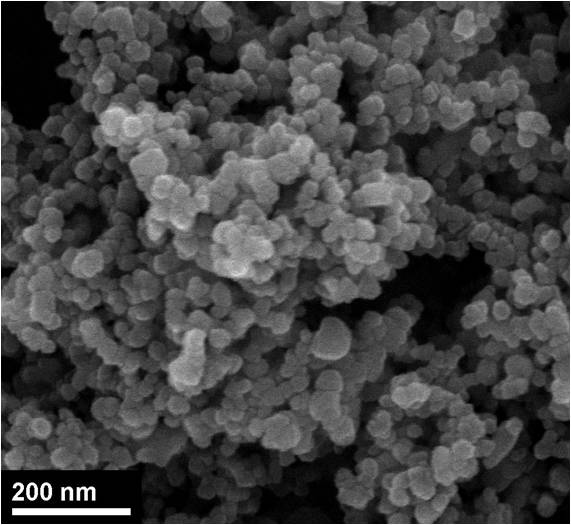

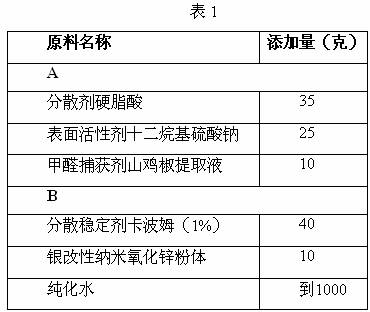

[0024] A kind of low-light photocatalyst composite aldehyde-removing spray, with 1 kilogram of this low-light photocatalyst composite aldehyde-removal spray, prepare a dispersion liquid with a zinc oxide content of 1%, and the particle diameter of the silver-modified nano-zinc oxide powder used is 30 Around nanometers, the ingredient list is as follows in Table 1:

[0025]

[0026] Preparation method: In container A, mix stearic acid, sodium lauryl sulfonate, and Litsea pepper extract according to the addition amount in the table, heat to 60°C, stir while heating to make it fully melt, Form a uniform and transparent liquid state; at the same time, in the B container, add carbomer to water and stir to form a uniform solution, then add silver-modified nano-zinc oxide powder, heat to 60°C, and stir while heating to form a dispersion Good slurry; then, under rapid stirring, add phase A at 70°C to phase B at 60°C, then use a high-speed homogenizer to homogenize for 2 minutes, an...

Embodiment 2

[0029] A kind of low-light photocatalyst composite aldehyde-removing spray, with 1 kilogram of this low-light photocatalyst composite aldehyde-removal spray, prepare a dispersion liquid with a zinc oxide content of 1%, and the particle diameter of the silver-modified nano-zinc oxide powder used is 30 Around nanometers, the ingredient list is as follows in Table 2:

[0030]

[0031]Preparation method: In container A, mix stearic acid, sodium lauryl sulfate, and lysozyme according to the addition amount in the table, heat to 50°C, stir while heating, make it fully melt, and form a uniform and transparent Liquid state; at the same time, in container B, add carbomer to water and stir to form a uniform solution, then add silver-modified nano-zinc oxide powder, heat to 80°C, and stir while heating to form a well-dispersed slurry; Then, under rapid stirring, add phase A at 50°C to phase B at 80°C, then use a high-speed homogenizer to homogenize for 2 minutes, and cool to room temp...

Embodiment 3

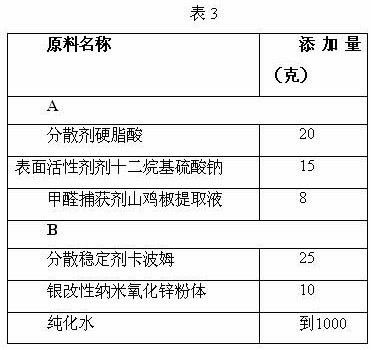

[0034] A kind of low-light photocatalyst composite aldehyde-removing spray, with 1 kilogram of this low-light photocatalyst composite aldehyde-removal spray, prepare a dispersion liquid with a zinc oxide content of 1%, and the particle diameter of the silver-modified nano-zinc oxide powder used is 30 Around nanometers, the ingredient list is as follows in Table 3:

[0035]

[0036] Preparation method: In container A, mix stearic acid, sodium lauryl sulfate, and lysozyme according to the addition amount in the table, heat to 60°C, stir while heating, make it fully melt, and form a uniform and transparent Liquid state; at the same time, in container B, add carbomer to water and stir to form a uniform solution, then add silver-modified nano-zinc oxide powder, heat to 70°C, and stir while heating to form a well-dispersed slurry; Then, under rapid stirring, add phase A at 60°C to phase B at 70°C, then use a high-speed homogenizer to homogenize for 2 minutes, and cool to room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com