Device and method for reducing content of light component impurities in polycrystalline silicon dry recovery process HCl absorption liquid

A technology of dry recovery and impurity content, applied in the direction of silicon, etc., can solve the problems of increasing the impurity content of polysilicon, low frequency and flow rate, and reducing the quality of polysilicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

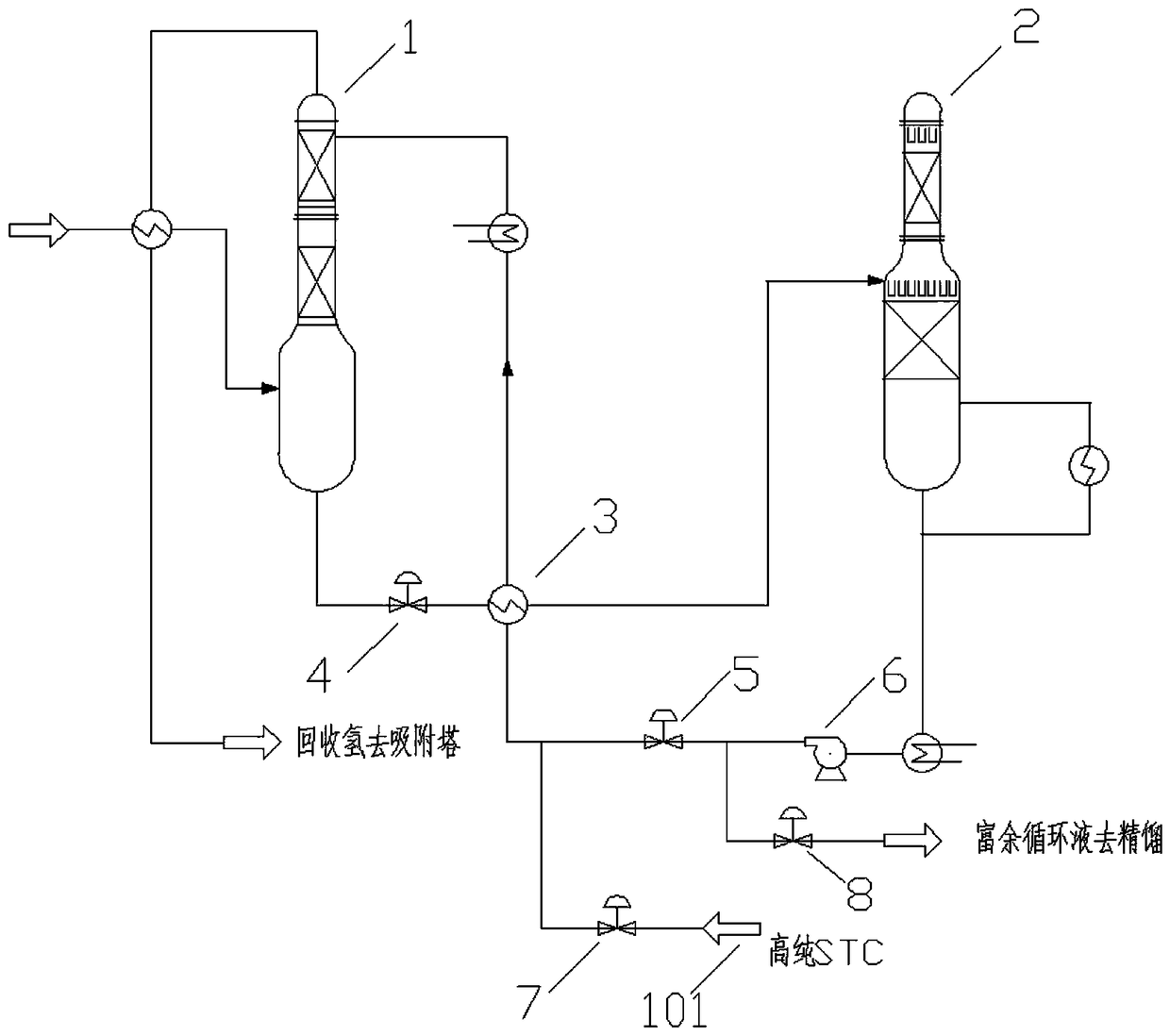

Image

Examples

Embodiment

[0025] 40m per hour 3 Combine the high-purity silicon tetrachloride (P content ≤ 1.5ppbw, B content ≤ 0.5ppbw) with a purity greater than 99% and the poor chlorosilane solution from the desorption tower into the top of the absorption tower for spraying, control the absorption tower and desorption The liquid level of the tower is constant, and the excess chlorosilane is discharged from the bottom of the desorption tower, so as to achieve the effect of diluting the HCl absorption liquid. The proportions and impurity contents of each main component in the HCl absorption liquid before and after implementation are as follows in Table 1:

[0026] Table 1 Comparison table of the proportion of each main component and impurity content in the HCl absorption liquid before and after implementation

[0027] Impurity name of each component

DCS

TCS

STC

B / ppbw

P / ppbw

Before implementation

16.45%

70.03%

12.94%

8.48

15.78

after implemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com