Biological organic foliar fertilizer for tea tree

A foliar fertilizer and biological technology, applied in the field of fertilizers, can solve the problems of inactivation of bacterial cells, low temperature preservation of unconditional fertilizers, etc., and achieve the effects of reducing the occurrence of diseases and insect pests, improving the quality of tea leaves, and improving the absorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A bio-organic foliar fertilizer for tea trees, which is prepared according to the following steps:

[0033]Preparation of cassava dregs-distiller's grains treatment: mix cassava dregs and distiller's grains (the moisture content of cassava residues and distiller's grains is 8wt%) according to a mass ratio of 3:1, then add to water, control the solid content to 30wt%, and then 500rpm Stir for 5 minutes, then raise the temperature to 60°C, under the condition of heat preservation, ultrasonic treatment for 30 minutes, the ultrasonic frequency is 25kHz, then steam treatment at 121°C for 10 minutes, and naturally cool to room temperature to obtain cassava residue-distiller's grain processed product;

[0034] Preparation of culture solution: mix Bacillus amyloliquefaciens seed solution and Trichoderma viride seed solution at a volume ratio of 2:3 to obtain a mixed inoculum, and mix the inoculation solution at 8% (accounting for the volume ratio of cassava residues-distiller’s ...

Embodiment 2

[0041] A bio-organic foliar fertilizer for tea trees, which is prepared according to the following steps:

[0042] Preparation of cassava dregs-distiller's grains treatment: mix cassava dregs and distiller's grains (the moisture content of cassava dregs and distiller's grains is 8wt%) according to a mass ratio of 2:1, then add to water, control the solid content to 30wt%, and then 500rpm Stir for 3 minutes, then raise the temperature to 50°C, under the condition of heat preservation, ultrasonic treatment for 30 minutes, the ultrasonic frequency is 20kHz, then steam treatment at 121°C for 10 minutes, and naturally cool to room temperature to obtain cassava residue-distiller's grain processed product;

[0043] Preparation of culture solution: Mix Bacillus amyloliquefaciens seed solution and Trichoderma viride seed solution at a volume ratio of 1:2 to obtain a mixed inoculum, and use 6% of the mixed inoculum (accounting for the volume ratio of cassava dregs-distiller’s grains) Th...

Embodiment 3

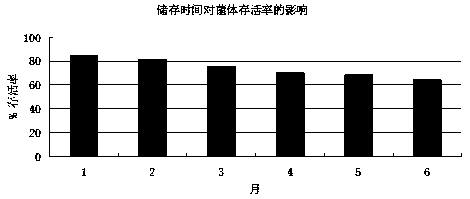

[0050] The influence of storage time on the survival rate of bacteria:

[0051] The survival rate of bacteria was detected at 1 month, 2 months, 3 months, 4 months, 5 months and 6 months, as figure 1 It can be seen that under normal temperature and dry conditions, the survival rate of the bacteria gradually decreases with time, but the rate of decline is not large. After 3 months, the survival rate of 75% can still be maintained, which has little effect on the fertilizer efficiency and can meet the market demand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com