Water displacement type thin-film antirust oil and preparation method thereof

A technology of water replacement and anti-rust oil, which is applied in the petroleum industry and lubricating compositions, etc. It can solve the problems of high cleanliness and dryness of workpieces, poor resistance to salt spray and damp heat, uneven oil film, etc., and achieve high-efficiency water Displacement speed, long anti-rust period, and high-efficiency water displacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

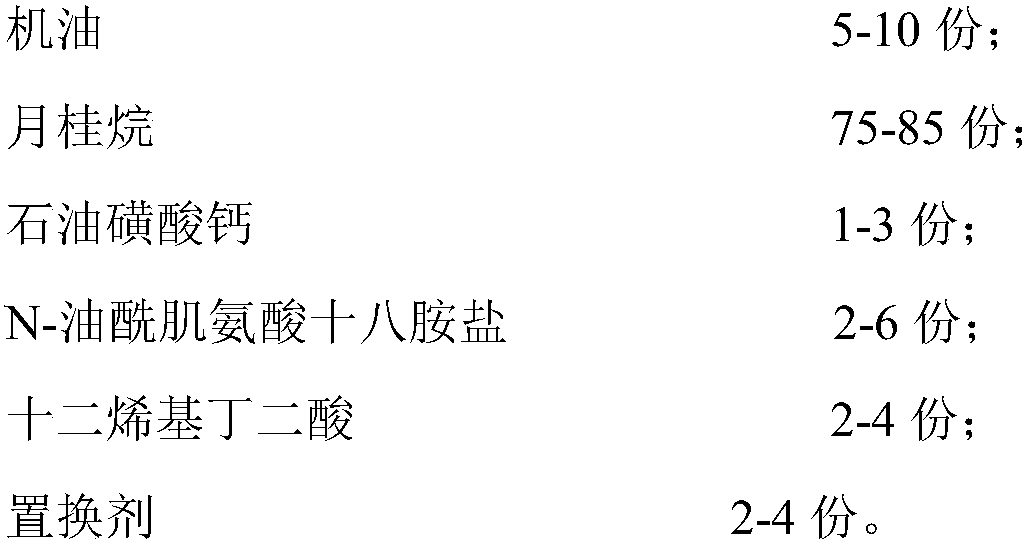

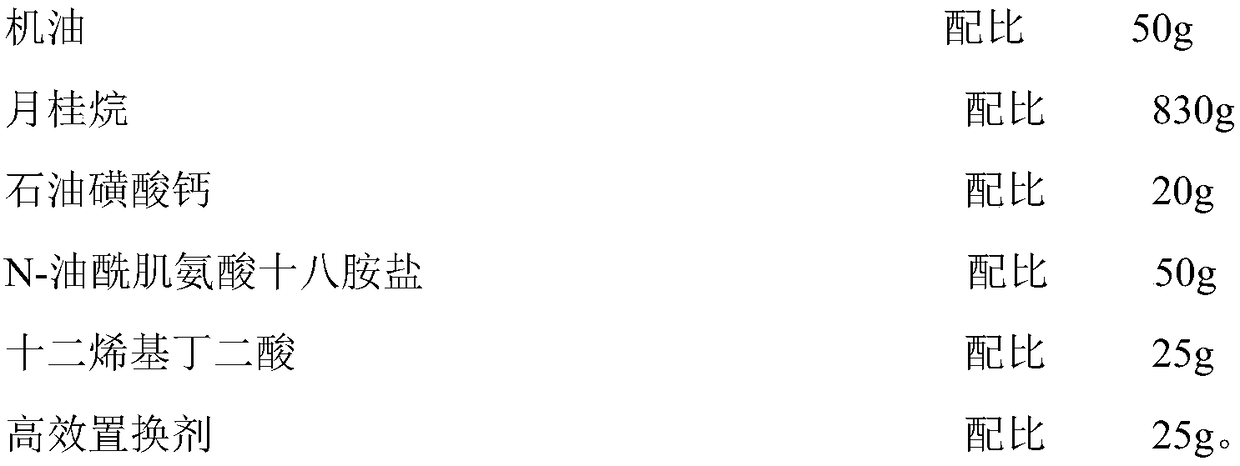

[0027] A water displacement type film antirust oil, its raw material composition and weight are respectively (taking 1000g water displacement type film antirust oil as an example):

[0028]

[0029] The preparation steps of above-mentioned water replacement type film antirust oil are as follows:

[0030] ⑴Put engine oil, calcium petroleum sulfonate, octadecylamine N-oleoyl sarcosine, and dodecenylsuccinic acid into the reactor, heat and stir the reactor, and control the temperature at 110°C-120°C , heated for about 30 minutes to completely dissolve the raw materials in the reactor and stir evenly;

[0031] (2) Cool the temperature of the material to about 60°C, add laurane and high-efficiency displacer, and stir for about 30 minutes until the mixture is uniform, and then the water-displacement type film anti-rust oil can be obtained, and the temperature of the reactor should be kept constant during the reaction.

[0032] Preferably, the engine oil is one or more mixtures o...

Embodiment 2

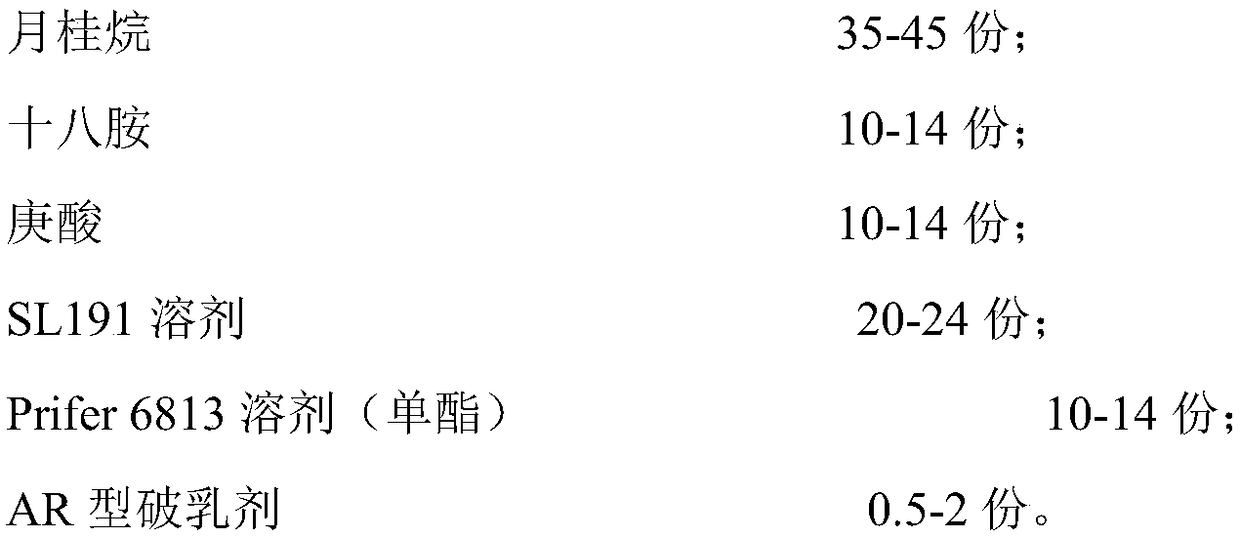

[0040] A water-displacing thin-film anti-rust oil, its raw material components and parts by weight are:

[0041]

[0042] The preparation method of the above-mentioned water-displacing type film antirust oil, the steps are as follows:

[0043] ⑴Put engine oil, calcium petroleum sulfonate, octadecylamine N-oleoyl sarcosine, and dodecenylsuccinic acid into the reactor, heat and stir the reactor, and control the temperature at 110°C-120°C , heated for 30 minutes to completely dissolve the raw materials in the reactor and stir evenly;

[0044] (2) Cool the temperature of the material to 60°C, add laurane and displacing agent, stir for 30 minutes until the mixture is uniform, and then the water displacement type film antirust oil can be obtained, and the temperature of the reactor should be kept constant during the reaction.

[0045] Preferably, the engine oil is one or more mixtures of 15# engine oil, 32# engine oil, 46# engine oil, and 68# engine oil;

[0046] Preferably, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com