Laundry sheet and preparation method thereof

A technology of laundry tablets and surfactants, applied in the field of laundry tablets and its preparation, can solve the problems of poor cleaning and decontamination effects of laundry tablets, and achieve good cleaning and decontamination effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

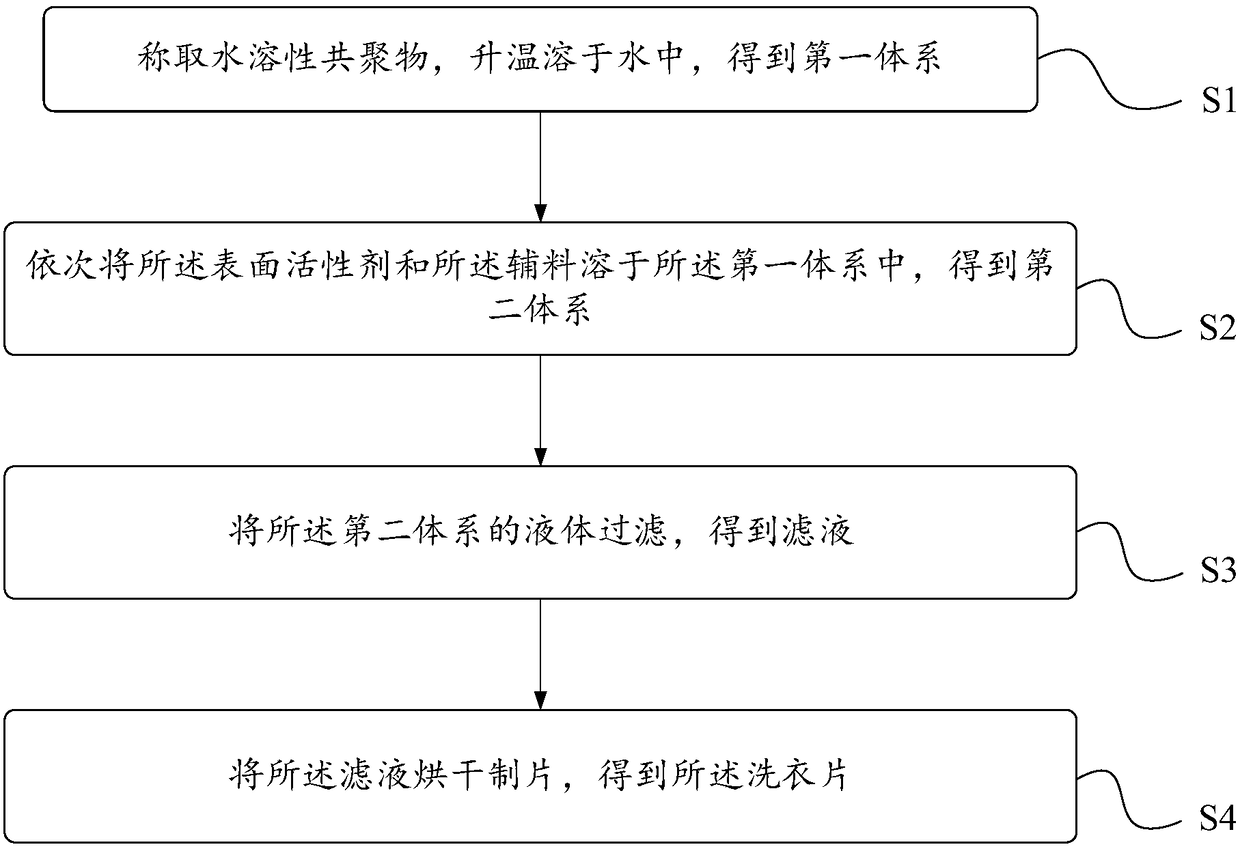

[0032] The preparation method of the laundry sheet of the present invention, such as figure 1 As shown, the following steps may be included:

[0033] S1: Weigh the water-soluble copolymer, heat it up and dissolve it in water to obtain the first system; specifically, according to the proportion of the formula, measure a certain amount of deionized water in a reaction container, and then slowly heat up the temperature while raising the temperature While adding a certain amount of water-soluble copolymer, after raising the temperature to 80-99° C., and then keeping the temperature for a period of time until the copolymer is completely swollen and uniform, the first system is obtained.

[0034]S2: Dissolve the surfactant and the auxiliary material in the first system in turn to obtain the second system; specifically, when adding the surfactant and the auxiliary material to dissolve, each time a raw material is added It must be ensured that it is completely dissolved before adding...

Embodiment 1

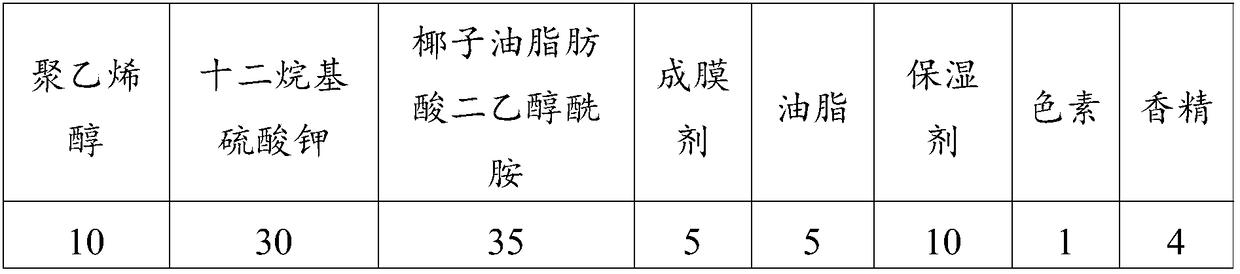

[0039] In this embodiment, the components of the laundry tablet include: polyvinyl alcohol, surfactants and auxiliary materials, wherein the surfactant includes potassium lauryl sulfate and coconut oil fatty acid diethanolamide, and the auxiliary materials include film-forming agents, grease, Moisturizing agent, pigment and essence, film forming agent is CMC, oil is polyether modified silicone oil, moisturizing agent is glycerin. The ratio of each component is shown in Table 1 below.

[0040] The composition and number of parts of table 1 laundry tablet

[0041]

[0042] The preparation method of this washing tablet is as follows:

[0043] S1: Measure 2.3L of deionized water into the reaction container, then raise the temperature, slowly add 1kg of polyvinyl alcohol and stir until the temperature rises to 80°C, and then keep the temperature for 60min;

[0044] S2: Dissolve 3kg of potassium lauryl sulfate and 3.5kg of coconut oil fatty acid diethanolamide in the solution a...

Embodiment 2

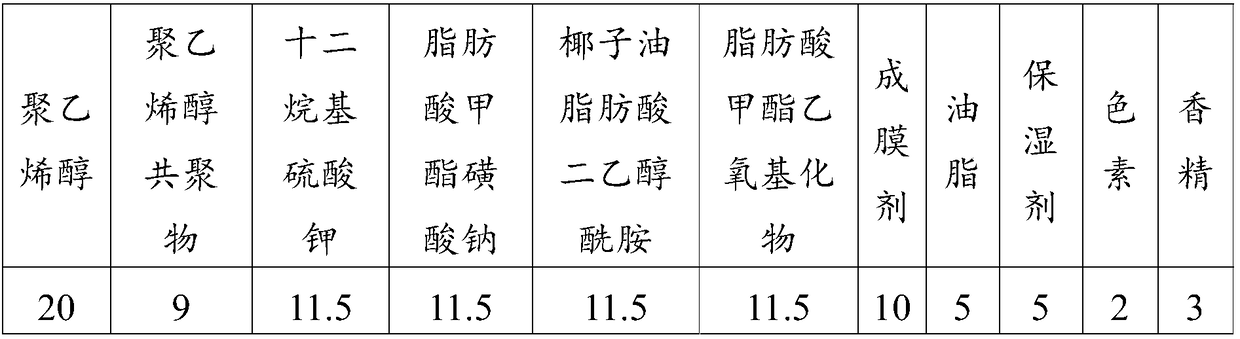

[0048] In this embodiment, the components of the laundry tablet include: a combination of polyvinyl alcohol and its copolymers, surfactants and auxiliary materials, wherein the surfactants include potassium lauryl sulfate, sodium fatty acid methyl ester sulfonate, coconut oil Fatty acid diethanolamide and fatty acid methyl ester ethoxylate. The auxiliary materials include film-forming agent, oil, moisturizer, pigment and flavor. The film-forming agent is HEC, the oil is methyl siloxane, and the moisturizing agent is propylene glycol. The ratio of each component is shown in Table 2 below.

[0049] Components and parts of table 2 laundry tablets

[0050]

[0051] The preparation method of this washing tablet is as follows:

[0052] S1: Measure 5.8L of deionized water into the reaction vessel, then raise the temperature, slowly add 2kg of polyvinyl alcohol and 0.5kg of polyvinyl alcohol copolymer during the heating process, stir until the temperature rises to 99°C, and then k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com