Preparation device for high-strength high-modulus polyethylene fiber spinning stock solution

A technology of polyethylene fiber and spinning dope, which is applied in spinning solution preparation, fiber treatment, filament forming treatment, etc., to achieve the effects of maintaining continuity, avoiding excessive proportion deviation, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

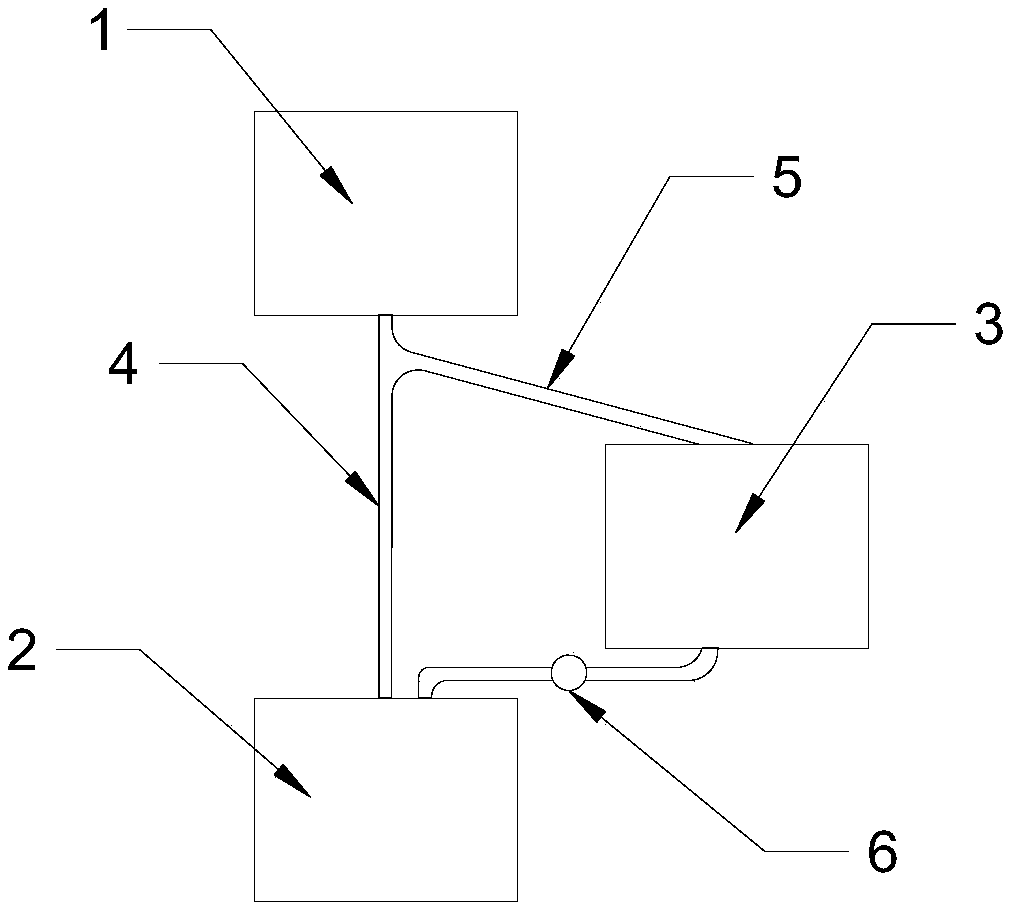

[0024] A high-strength high-modulus polyethylene fiber spinning dope preparation device, see figure 1 with figure 2 , which includes a spinning stock solution controller, a feeding kettle, a feeding kettle 2, a feeding pipe 4, an overflow pipe 5, a circulating kettle 3 and a circulating pump 6, wherein:

[0025] The feeding kettle is connected to the feeding kettle 2 through the feeding pipe 4, the first end of the overflow pipe 5 is connected to the feeding pipe 4, the second end of the overflow pipe 5 is connected to the feeding kettle 2, the circulating kettle 3 and the circulating The pumps 6 are all installed on the overflow pipe 5, the control end of the circulating pump 6 is connected with the spinning stock solution controller signal, and the overflow pipe 5, the circulating kettle 3 and the circulating pump 6 are arranged to keep the spinning stock solution in a flowing state, which is beneficial to The PE powder is fully dissolved in the solvent without precipitati...

Embodiment 2

[0029] On the basis of Example 1, a structure of the powder metering scale is as follows: it includes a servo motor and a screw conveyor driven by the servo motor, the control end of the servo motor is connected with the signal of the spinning stock solution controller, and the spinning stock solution control The device controls the rotation speed of the servo motor to keep the spinning stock solution in a flowing state all the time, so as to prevent the precipitation of PE powder, which is beneficial to the later spinning and other operations.

[0030] The solvent feeding mechanism includes a solvent feeding pipe, a feeding pump installed on the solvent feeding pipe and a flow valve. The control end of the flow valve is connected to the signal of the spinning dope controller. The spinning dope controller controls the opening time and opening time of the flow valve. The degree of automatic and precise control of the amount of solvent fed into the feeding tank ensures that the f...

Embodiment 3

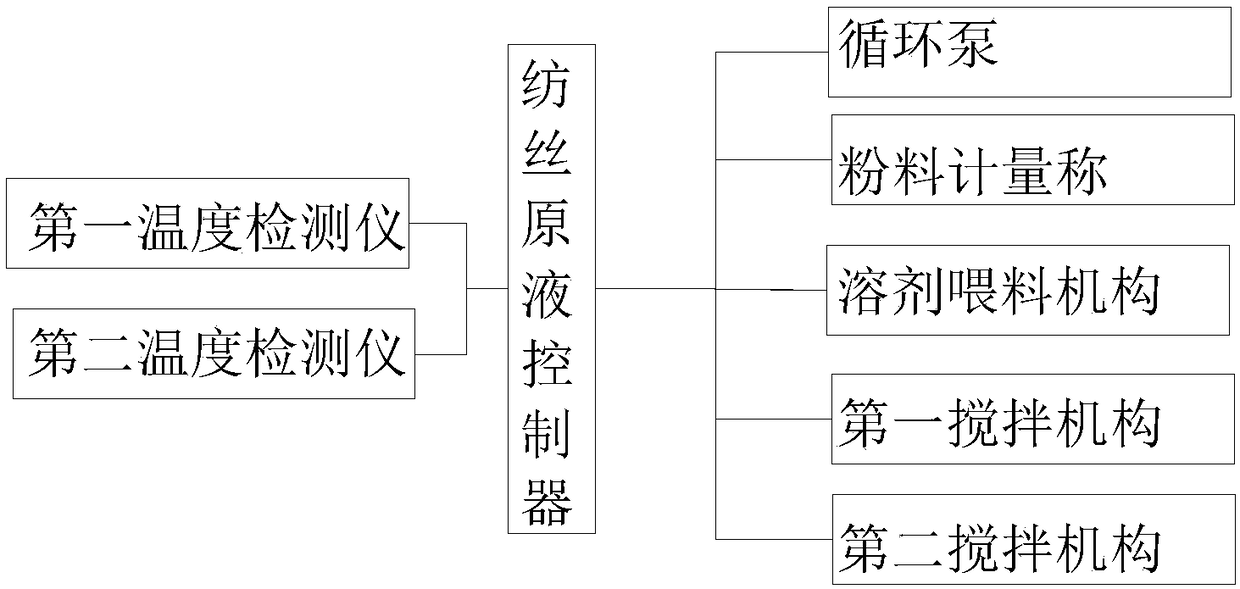

[0033] The feeding kettle is provided with a first heating assembly and a first temperature detector, and the control end of the first heating assembly and the signal output end of the first temperature detector are both connected to the spinning dope controller for signals;

[0034] The circulating kettle 3 is provided with a second heating assembly and a second temperature detector. The control end of the second heating assembly and the signal output end of the second temperature detector are all connected to the spinning dope controller signal, and the first temperature detector and the second temperature detector are detected separately, and the temperature in the feeding kettle is automatically controlled by the first heating assembly, the spinning dope controller, and the first temperature detector. Closed loop, when the first temperature detector detects the temperature in the feeding kettle After the temperature is lower than the corresponding temperature threshold stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com