A device and method for monitoring horizontal displacement in the whole process of concrete dam construction and operation

A technology for horizontal displacement and concrete dams, applied in measuring devices, buildings, sea area engineering, etc., can solve problems such as inability to monitor, achieve the effect of avoiding concrete entry and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained in detail below in conjunction with the drawings and specific embodiments, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

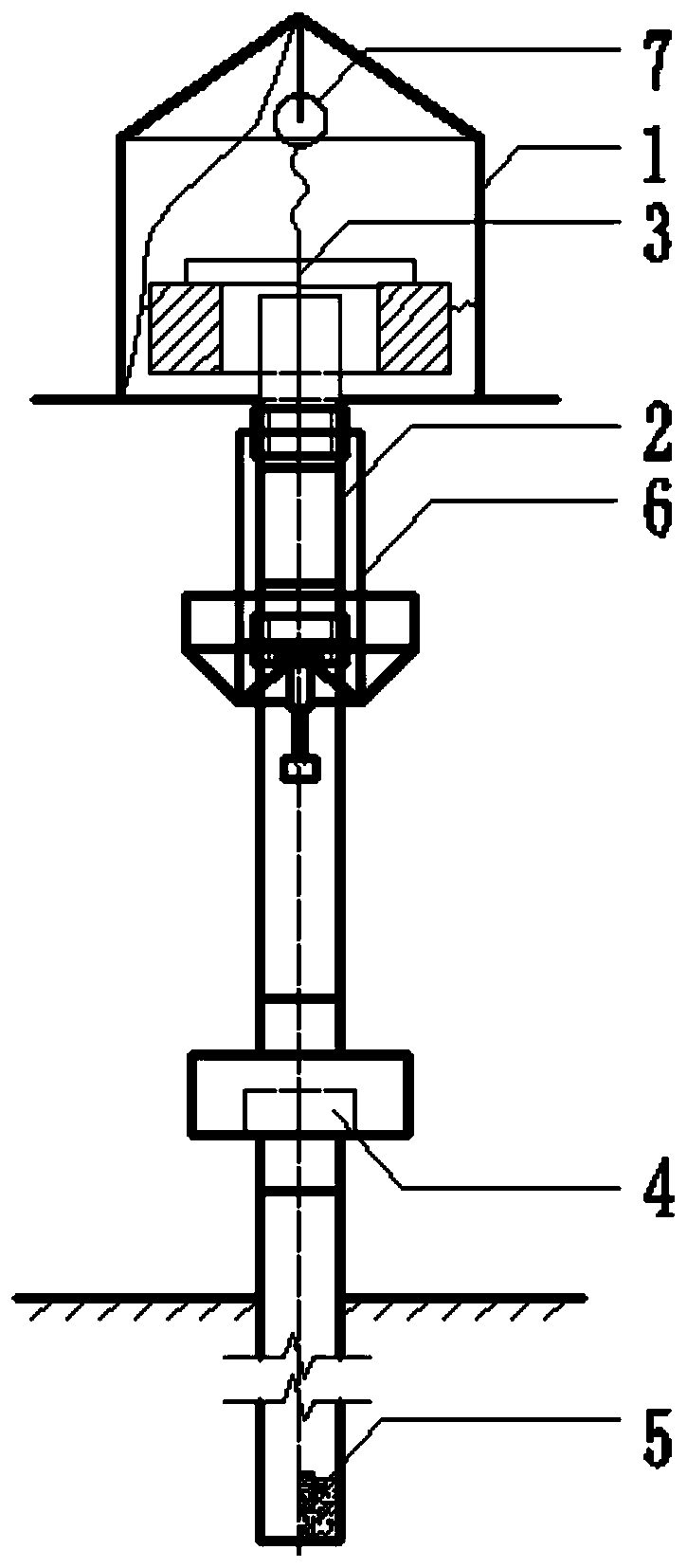

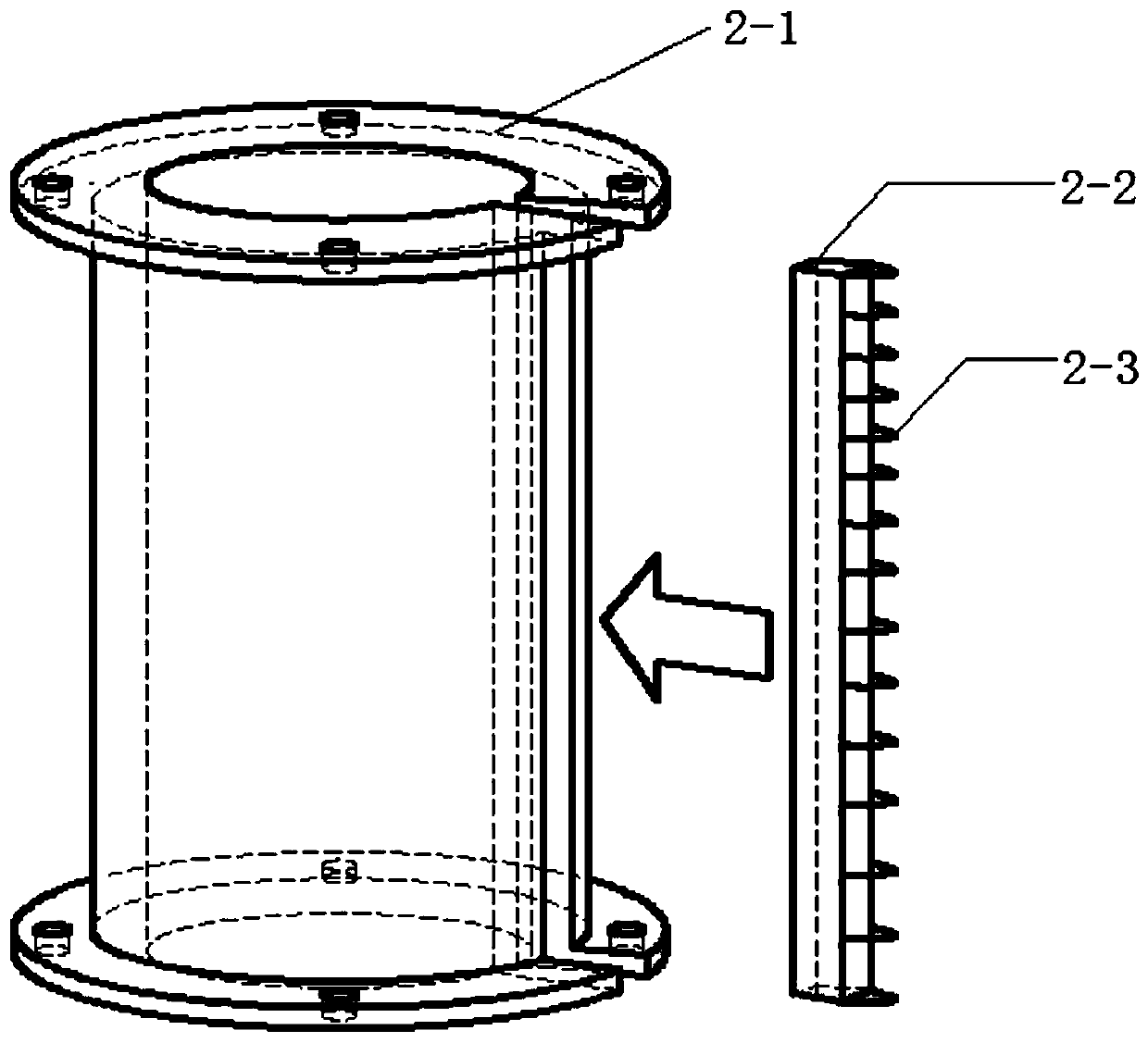

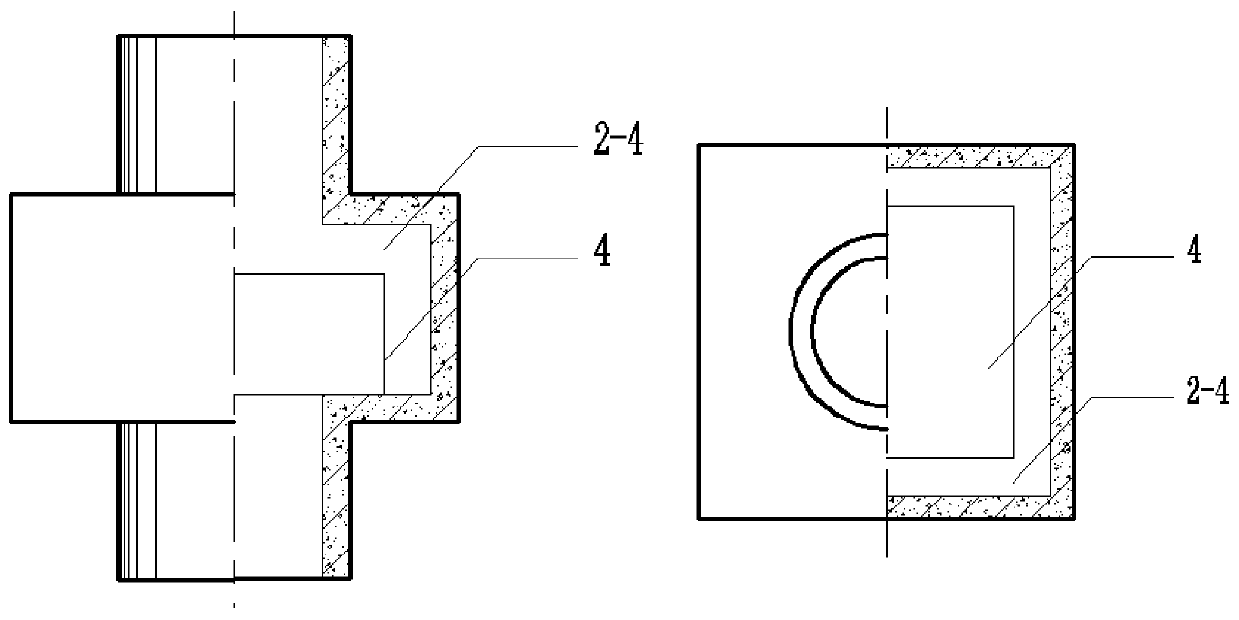

[0037] Such as figure 1 As shown, the horizontal displacement monitoring device for the whole process of concrete dam construction and operation in the present invention includes a reference line 3, a pipe sleeve placed outside the reference line 3 for protecting the reference line 3, and used to ensure that the reference line 3 is always in the vertical direction. The buoyancy device 1 and the horizontal displacement monitor 4 for monitoring the horizontal displacement of the dam. Such as Figure 4-6 The buoyancy device 1 includes a buoy protection cover 1-1, an oil cylinder placed in the buoy protection cover 1-1, and a float. The oil cylinder contains an antifreeze and anti-volatile floating liquid, and the float floats on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com