Noise lowering method for aerodynamic noise of wind turbine blade

A technology of wind turbine blades and aerodynamic noise, which is applied in the field of noise reduction devices, can solve problems affecting the aerodynamic performance of the airfoil surface, and achieve the effects of facilitating integrated design, weakening diffraction, and obvious noise reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

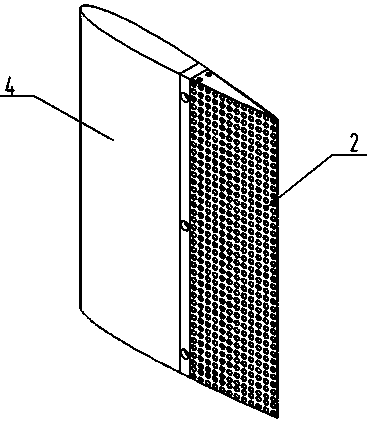

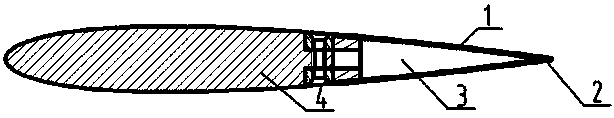

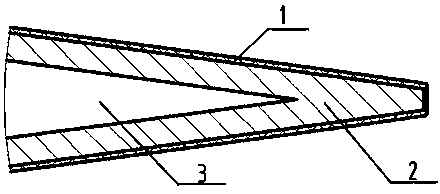

[0025] Such as figure 1 As shown, it is the overall structure of the blade, and the overall structure adopts a gradual structure; it is divided into the main body of the blade and the trailing edge of the blade, and the main body of the blade and the trailing edge of the blade are connected as a whole through a connecting structure, as shown in figure 2 shown. The connection structure adopts an internal connection method, so that the main body of the blade is fixedly connected with the trailing edge of the blade, and the surface of the main body of the blade and the trailing edge of the blade is guaranteed to be smooth and gradual.

[0026] In this example, the adoption of the impedance gradient structure is fundamental to solve the noise problem at the trailing edge of the blade. It is composed of sound-transmitting material on the outer surface, a support frame in the middle, and sound-absorbing material filled inside from the outside to the inside; the sound-transmitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com