A device for measuring gas diffusion coefficient in coal shale

A gas diffusion and measurement device technology, applied in measurement devices, instruments, surface/boundary effects, etc., can solve the problems of destroying the spatial structure of coal shale, large differences in diffusion coefficients, and small production cycle, and simplify the experimental operation steps. , the effect of reducing external factors and increasing the time of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

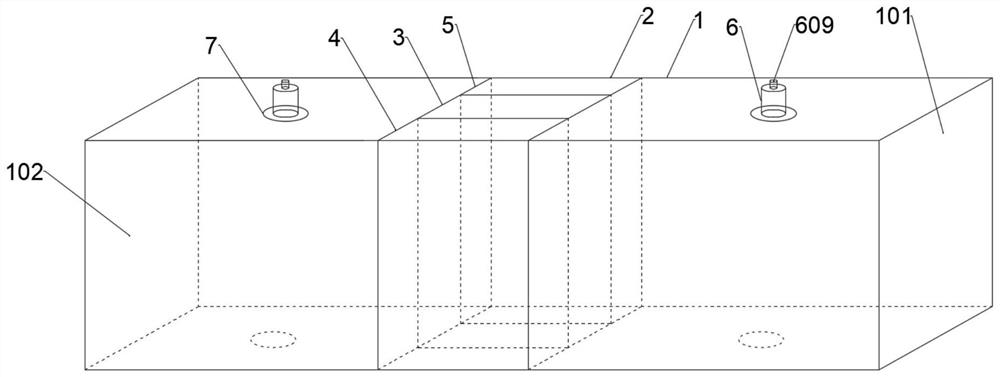

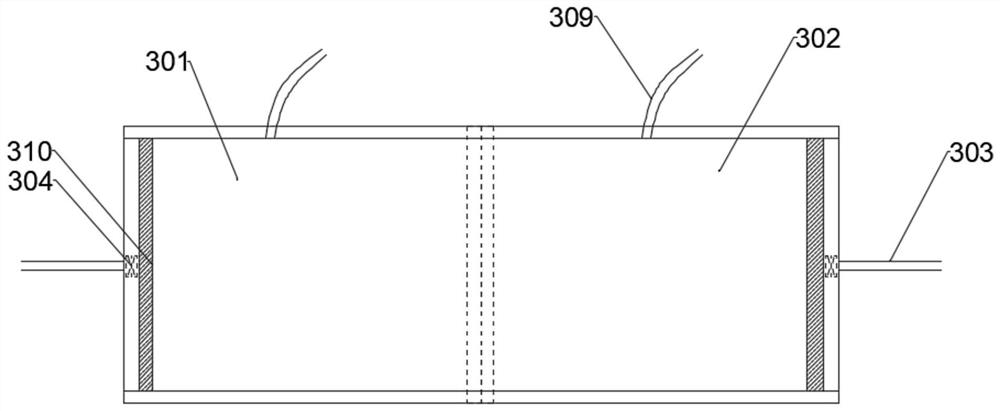

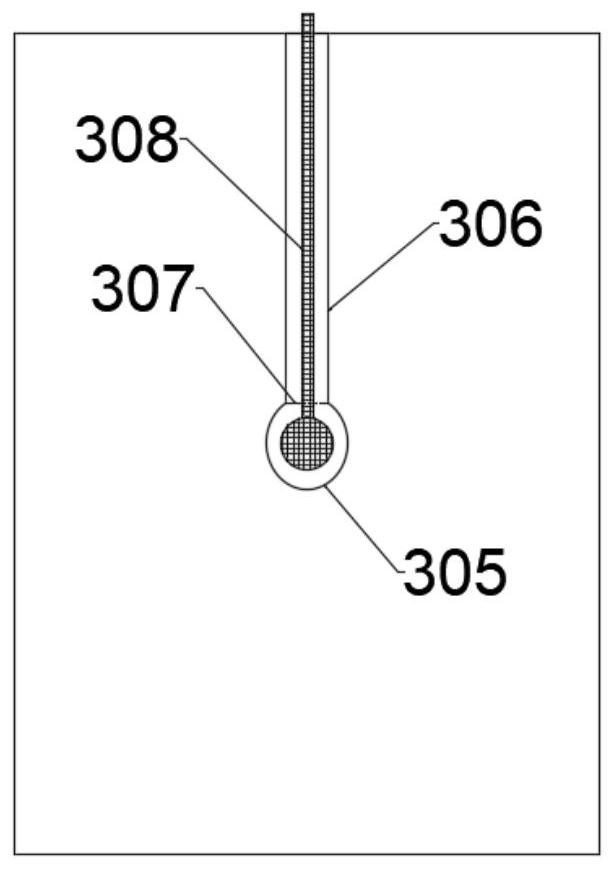

[0052] Such as figure 1 As shown, the present invention provides a gas diffusion coefficient measuring device in coal shale, comprising an experimental cabin 1, the interior of the experimental cabin 1 is divided into a left experimental chamber 101 and a right experimental chamber by a double-layer sealed partition 2 102, a storage pump 3 for storing gas, a gas chromatograph gas path system 4 for measuring the gas concentration in the left experimental chamber 101 and the right experimental chamber 102 are integrated between the double-layer sealed partitions 2, For the gas pressure change detection device 5 for measuring the pressure values in the left experimental chamber 101 and the right experimental chamber 102, the inner walls of the left experimental chamber 101 and the right experimental chamber 102 are provided with sample clamping and sealing installation holes 7.

[0053] The basic point of the existing gas diffusion coefficient measurement device in coal shale ...

Embodiment 2

[0094] The present invention provides an experimental test method for gas diffusion coefficient based on the gas diffusion coefficient measuring device. It includes the following steps:

[0095] Step 100, measuring the pressure change curve in the experimental chamber of the core sample at a set temperature;

[0096] Step 200, measuring the gas concentration variation curve in the experimental chamber of the core sample at a set temperature;

[0097] Step 300, according to Fick's second law, respectively calculate the diffusion coefficients of step 100 and step 200.

[0098] Step 400, comparing the diffusion coefficients measured in step 100 and step 200, and comprehensively obtaining the gas diffusion coefficient of the core sample.

[0099] In this embodiment, the two methods of measuring the gas diffusion coefficient of the core sample can be skillfully combined on the same whole through relatively small equipment requirements, namely the gas concentration and pressure me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com