A preparation method of electrodepositing high permeability iron-nickel alloy film on aluminum matrix composite material

A technology of aluminum-based composite materials and iron-nickel alloys, applied in the application of magnetic films to substrates, shielding materials, metal material coating processes, etc., can solve problems such as poor magnetic field shielding performance, achieve low cost, and simple operation process , High magnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

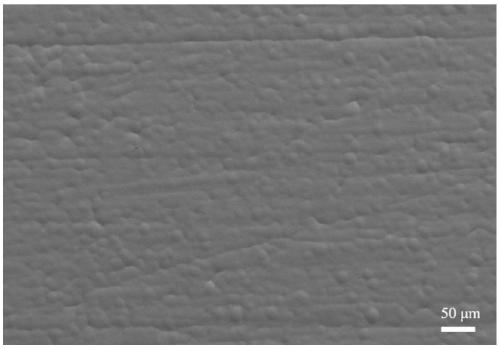

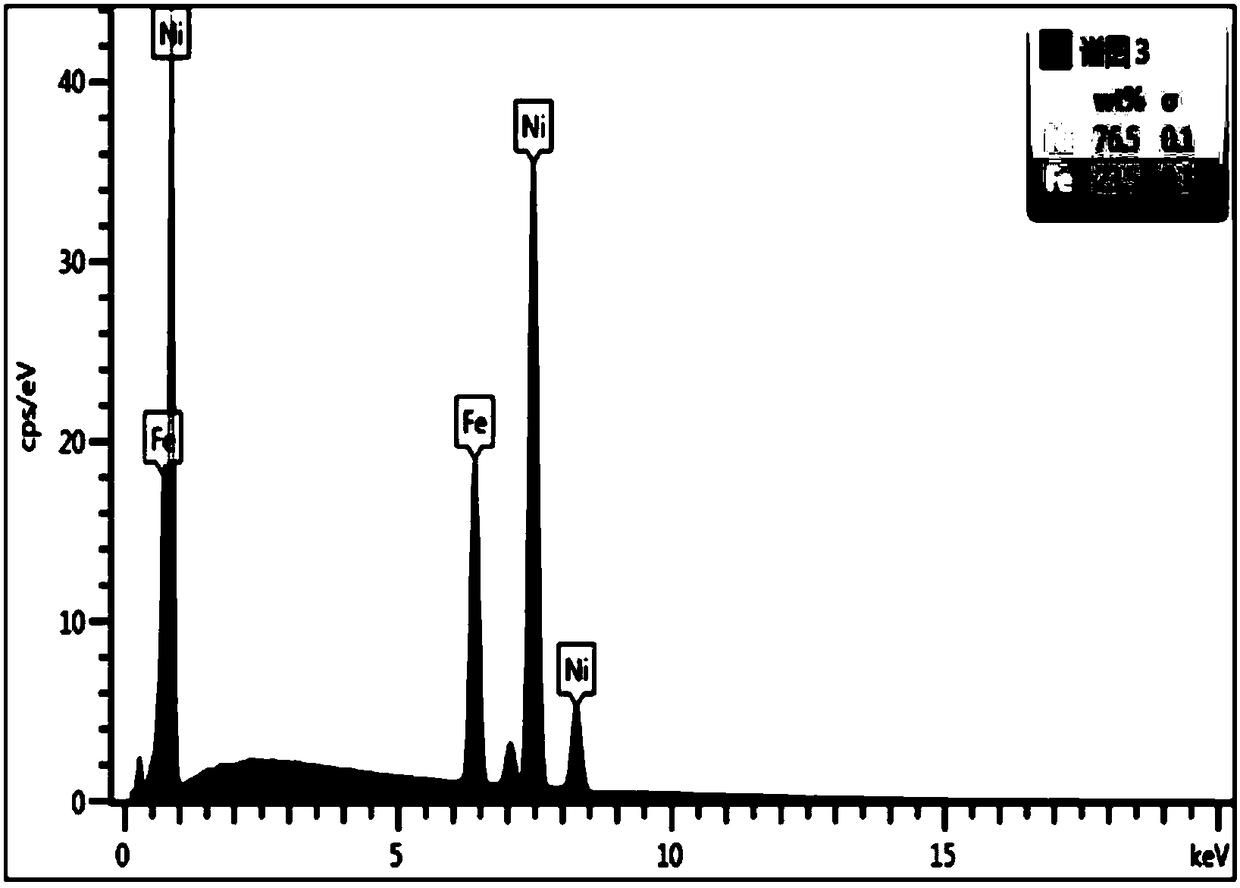

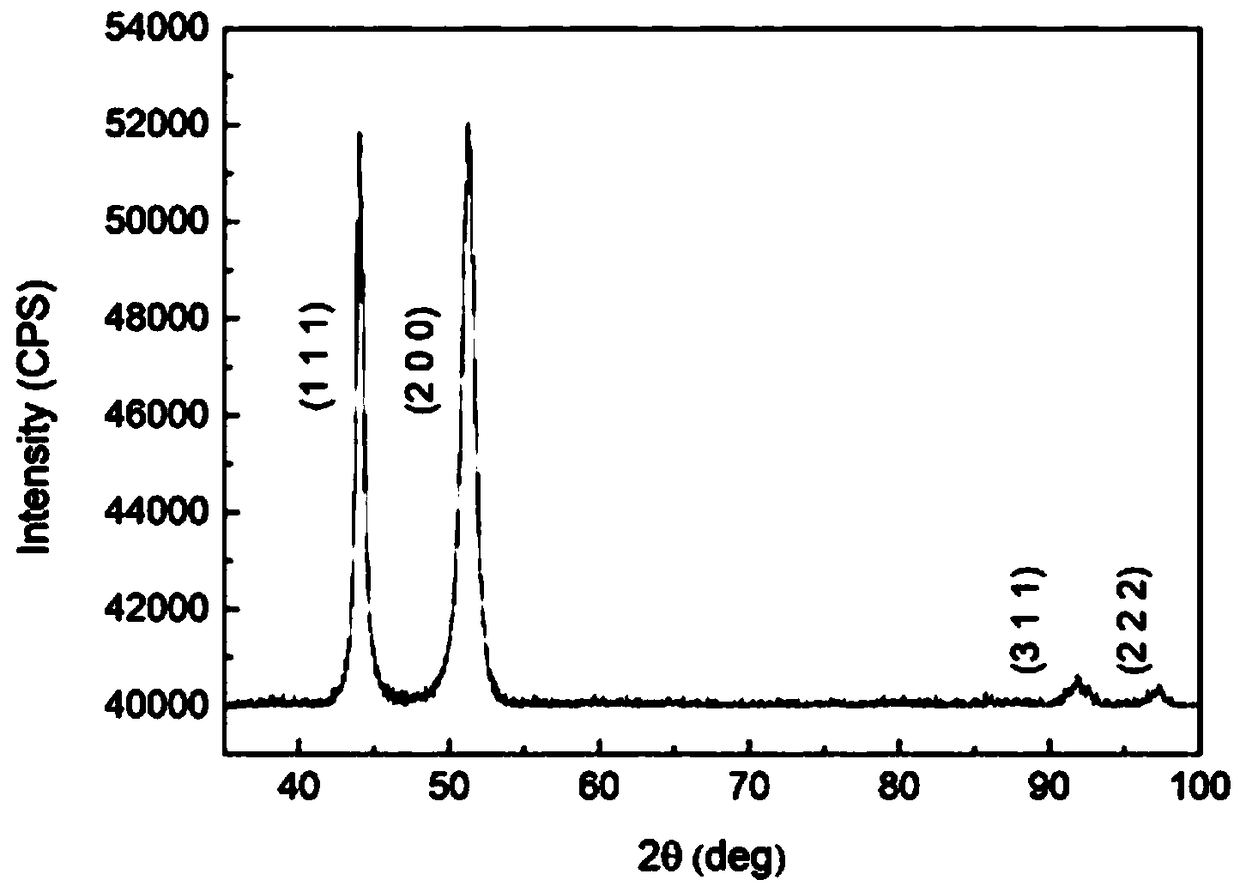

Image

Examples

specific Embodiment approach 1

[0021] Specific Embodiment 1: In this embodiment, a method for preparing an electrodeposited high-permeability iron-nickel alloy film on an aluminum-based composite material is carried out according to the following steps: 1. Remove oil stains on the surface of the aluminum-based composite material: the ceramic particles are reinforced with aluminum The matrix composite material is immersed in a mixed solution A at a temperature of 60-85°C for 2-3 minutes to obtain a ceramic particle-reinforced aluminum matrix composite material that removes surface oil; the mixed solution A is composed of Na 3 PO 3 and Na 2 SiO 3 Mixed, Na in mixed solution A 3 PO 3 The concentration is 40~60g / L, Na 2 SiO 3 The concentration is 15~30g / L;

[0022] 2. Pickling and light removal: at room temperature, the ceramic particle-reinforced aluminum matrix composite material that removes surface oil is immersed in HNO 3 Pickling in the solution for 40-50s to obtain the pickled ceramic particle rei...

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is: HNO in step two and step four 3 The solution volume concentration is 50%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that Na in the mixed solution A 3 PO 3 The concentration is 45~55g / L, Na 2 SiO 3 The concentration is 20~25g / L. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com