Poly-heterocyclic ring based acrylate monomer modified waterborne hydroxy acrylic dispersion and preparation method thereof

A technology of heterocyclic acrylic acid ester and hydroxyacrylic acid is applied in the field of water-based hydroxyacrylic acid dispersion and its preparation, which can solve the problems of increasing production cost, hidden dangers of safety, increasing production cycle and high reaction temperature, and achieves increasing paint film adhesion, Increased film hardness and high solids content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

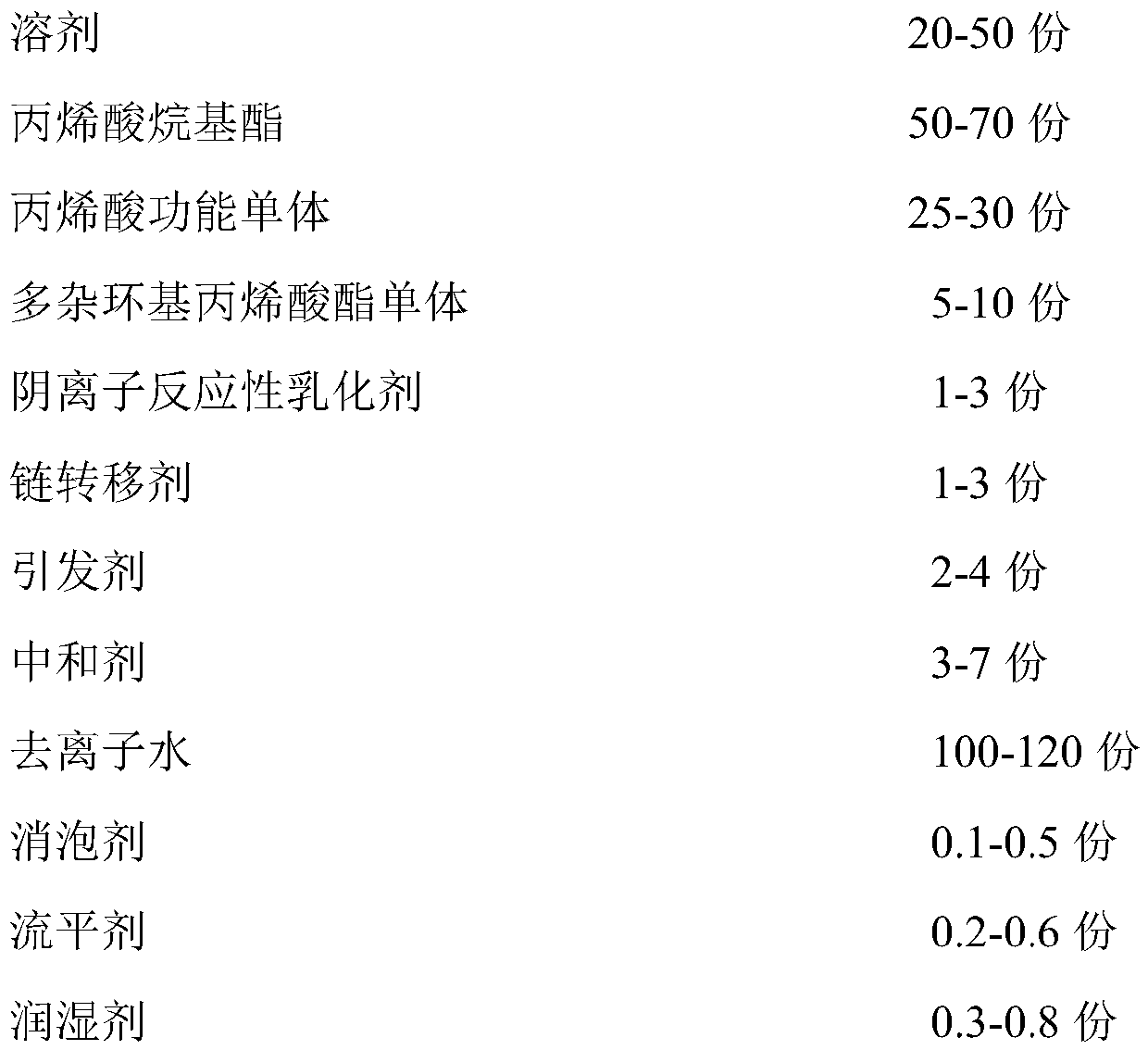

[0041] The preparation method of the aqueous hydroxyacrylic acid dispersion modified by polyheterocyclic acrylate monomer comprises the steps:

[0042] 1) Solution polymerization: In parts by mass, 20 parts of acetone solvent and 5 parts of isobornyl acrylate were mixed into a four-necked flask, and the temperature was raised to 70°C; 30 parts of methyl methacrylate, 20 parts of acrylate Butyl ester, 23 parts of hydroxypropyl acrylate, 1 part of glycidyl methacrylate, 2 parts of acrylic acid, 1 part of dodecanethiol and 2 parts of azobisisobutyronitrile are mixed to obtain mixed monomers; take out 5wt% of mixed monomers The monomer was quickly added to the four-necked flask, and kept at 70°C for 15 minutes; after the insulation was completed, the remaining 95% of the mixed monomer and 1 part of SR-10 were fed into the four-necked flask within 4 hours. In the flask, keep warm for 1 hour after the dropwise addition is completed. Lower the temperature to below 50°C, and add 3 pa...

Embodiment 2

[0046] The preparation method of the aqueous hydroxyacrylic acid dispersion modified by polyheterocyclic acrylate monomer comprises the steps:

[0047] 1) Solution polymerization: in parts by mass, 20 parts of acetone, 10 parts of methyl ethyl ketone and 6 parts of isobornyl methacrylate were mixed into a four-necked flask, and the temperature was raised to 72°C; Methyl acrylate, 25 parts of n-butyl acrylate, 25 parts of hydroxyethyl acrylate, 2 parts of glycidyl methacrylate, 3 parts of methacrylic acid, 2 parts of mercaptoethanol and 2.5 parts of azobisisoheptanonitrile were mixed to obtain Mixed monomers; take out 6wt% of mixed monomers and quickly add them to the four-necked flask, and incubate at 72°C for 20 minutes; Feed together and join in the described four-neck flask, keep warm for 1 hour after the dropwise addition is completed. Lower the temperature to below 50°C, and add 4 parts of N,N-dimethylethanolamine dropwise within 30 minutes.

[0048] 2) Acetone treatmen...

Embodiment 3

[0051] The preparation method of the aqueous hydroxyacrylic acid dispersion modified by polyheterocyclic acrylate monomer comprises the steps:

[0052] 1) Solution polymerization: in parts by mass, 30 parts of acetone, 20 parts of propylene glycol butyl ether and 7 parts of polyheterocyclic acrylate monomer SW914 were mixed into a four-necked flask, and the temperature was raised to 74°C; 30 parts Ethyl acrylate, 30 parts of n-butyl acrylate, 26 parts of hydroxyethyl methacrylate, 3 parts of glycidyl methacrylate, 4 parts of acrylic acid, 3 parts of mercaptopropionic acid and 3 parts of benzoyl peroxide are mixed to obtain a mixture monomer; take out 7wt% of the mixed monomer and quickly add it to the four-necked flask, and keep it warm at 74°C for 25 minutes; The feed was added to the four-neck flask, and the temperature was kept for 1 hour after the dropwise addition was completed. Lower the temperature to below 50°C, and add 5 parts of triethanolamine dropwise within 30 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com