Radioactive organic waste liquid treatment device and method thereof

A technology of organic waste liquid and treatment device, which is applied in radioactive purification, nuclear engineering and other directions, can solve problems such as energy waste, and achieve the effect of solving hidden safety hazards, avoiding pipeline blockage and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

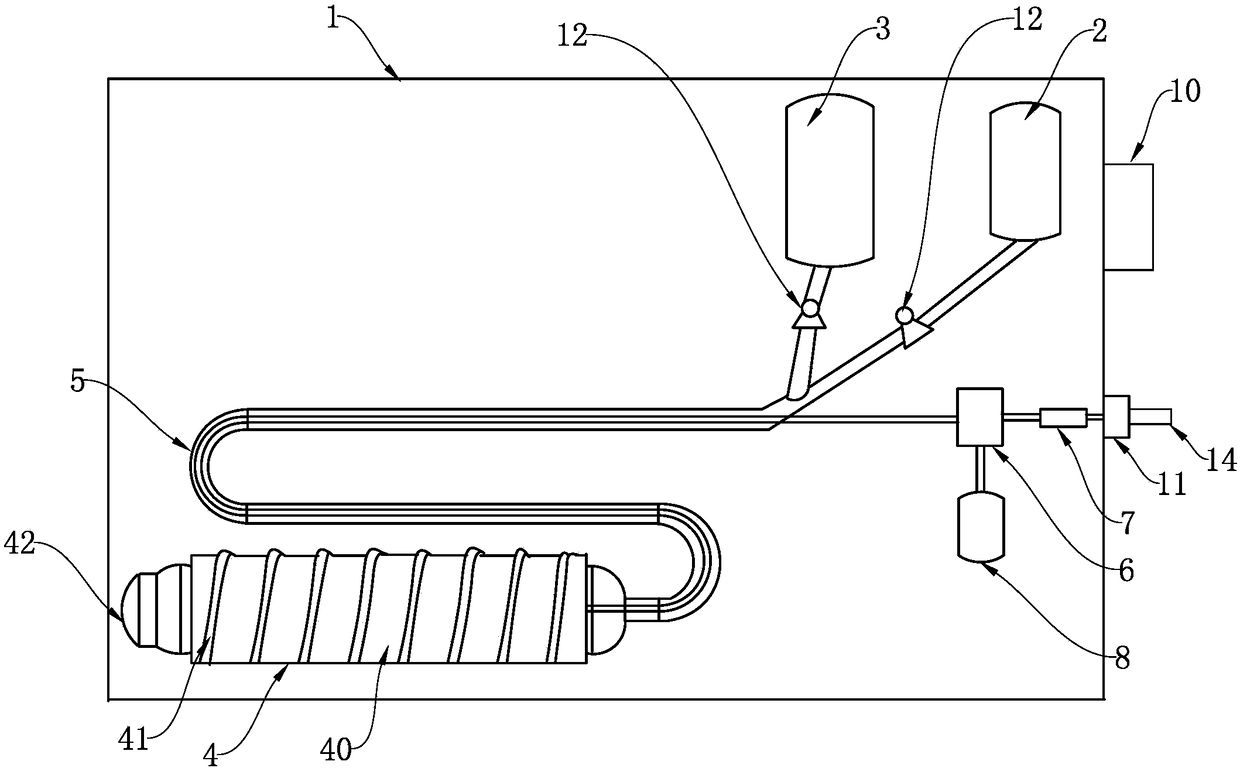

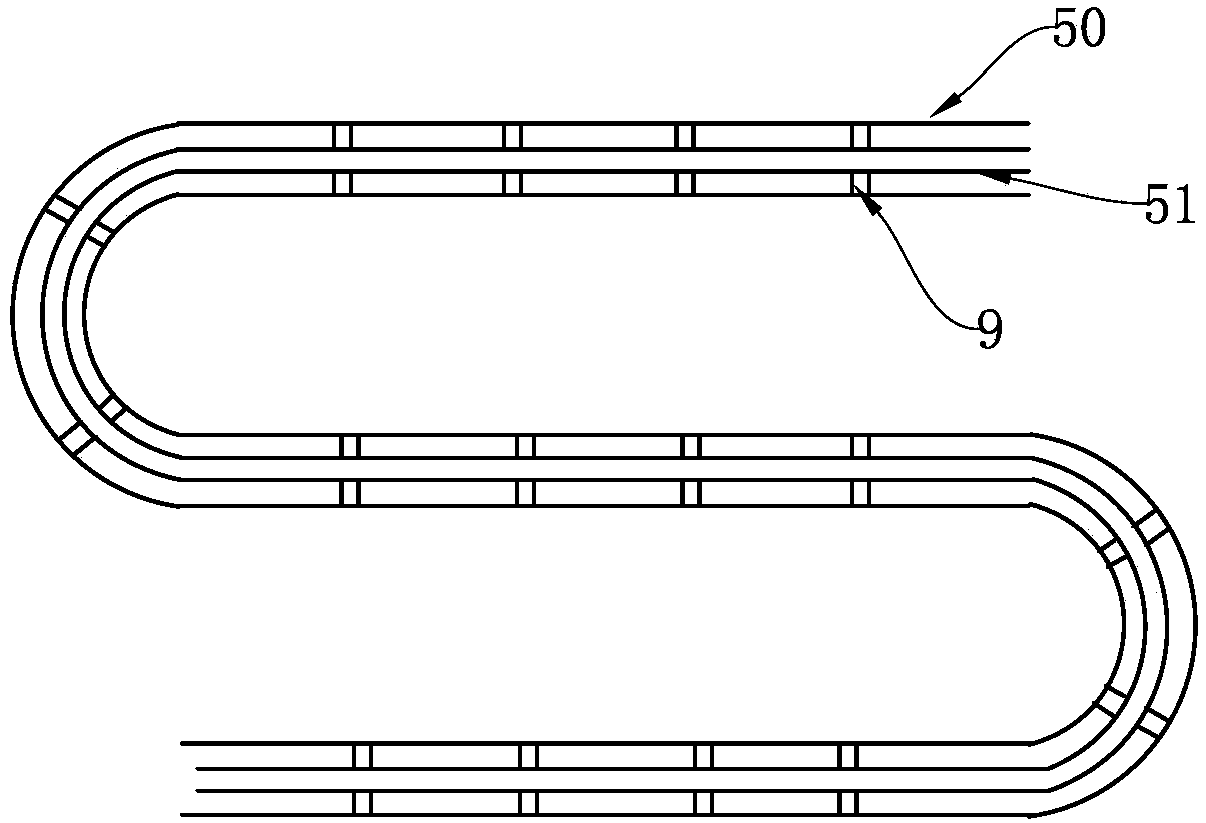

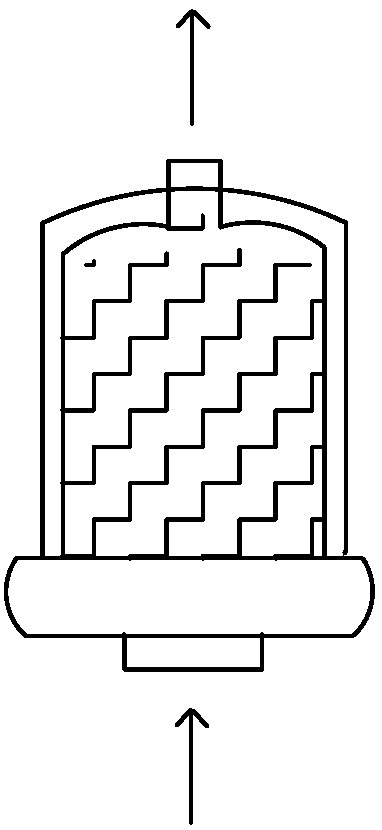

[0036] A radioactive organic waste treatment device, such as figure 1 As shown, a glove box 1 is included, and the glove box 1 is provided with a waste liquid storage tank 2, a hydrogen peroxide storage tank 3, a reaction tank 4, a product collection device and a delivery pipeline 5, and the outlet of the waste liquid storage tank 2 is provided with a waste liquid high-pressure pump 12. The hydrogen peroxide storage tank 3 outlet is provided with a hydrogen peroxide high-pressure pump 13; the delivery pipeline 5 includes a delivery inner tube 50 and a delivery outer tube 51 sleeved outside the delivery inner tube 50, and one end of the delivery inner tube 50 extends into the inside of the reaction tank 4, and the other One end passes through the delivery outer pipe 51, and the waste liquid storage tank 2 and the hydrogen peroxide storage tank 3 are respectively connected to the inlet of the reaction tank 4 through the delivery outer pipe 51, and the reaction tank 4 is connected...

Embodiment 2

[0048] A method for treating organic waste liquid with a radioactive organic waste liquid treatment device, comprising the following steps:

[0049] (1) The radioactive organic waste liquid (vacuum pump oil in the nuclear power plant loop system) and hydrogen peroxide are transported to the reaction tank through the waste liquid high-pressure pump and the hydrogen peroxide high-pressure pump respectively according to the volume ratio of 1:15;

[0050] (2) Start the heating device and the cooling device through the control panel to control the temperature in the reaction tank at 450°C, and the reaction pressure at 25Mpa;

[0051] (3) The reaction product is transported to the product collection device through the transport inner tube, and at the same time, the heat of the reaction product is used to preheat the organic waste liquid and hydrogen peroxide in the transport outer tube;

[0052] (4) After the reaction product is separated by the gas-liquid separator, the gas product...

Embodiment 3

[0054] A method for treating organic waste liquid with a radioactive organic waste liquid treatment device, comprising the following steps:

[0055] (1) The radioactive organic waste liquid (TBP+ diluent) and hydrogen peroxide are transported to the reaction tank through the waste liquid high-pressure pump and the hydrogen peroxide high-pressure pump respectively according to the volume ratio of 1:20;

[0056] (2) Start the heating device and the cooling device through the control panel to control the temperature in the reaction tank at 500°C, and the reaction pressure at 25Mpa;

[0057] (3) The reaction product is transported to the product collection device through the transport inner tube, and at the same time, the heat of the reaction product is used to preheat the organic waste liquid and hydrogen peroxide in the transport outer tube;

[0058] (4) After the reaction product is separated by the gas-liquid separator, the gas product is discharged into the atmosphere after b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com