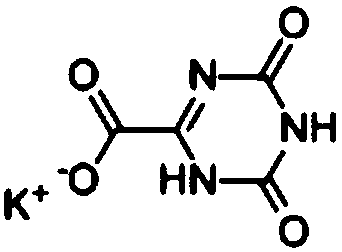

Stable oteracil potassium suspension and preparation method thereof

A technology of potassium oxonate and preparation method, which is applied in the direction of medical formula, medical preparation of non-effective ingredients, liquid delivery, etc., can solve the problems of injecting mice with soaking cells, prevent precipitation, improve stability, and enhance The effect of dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

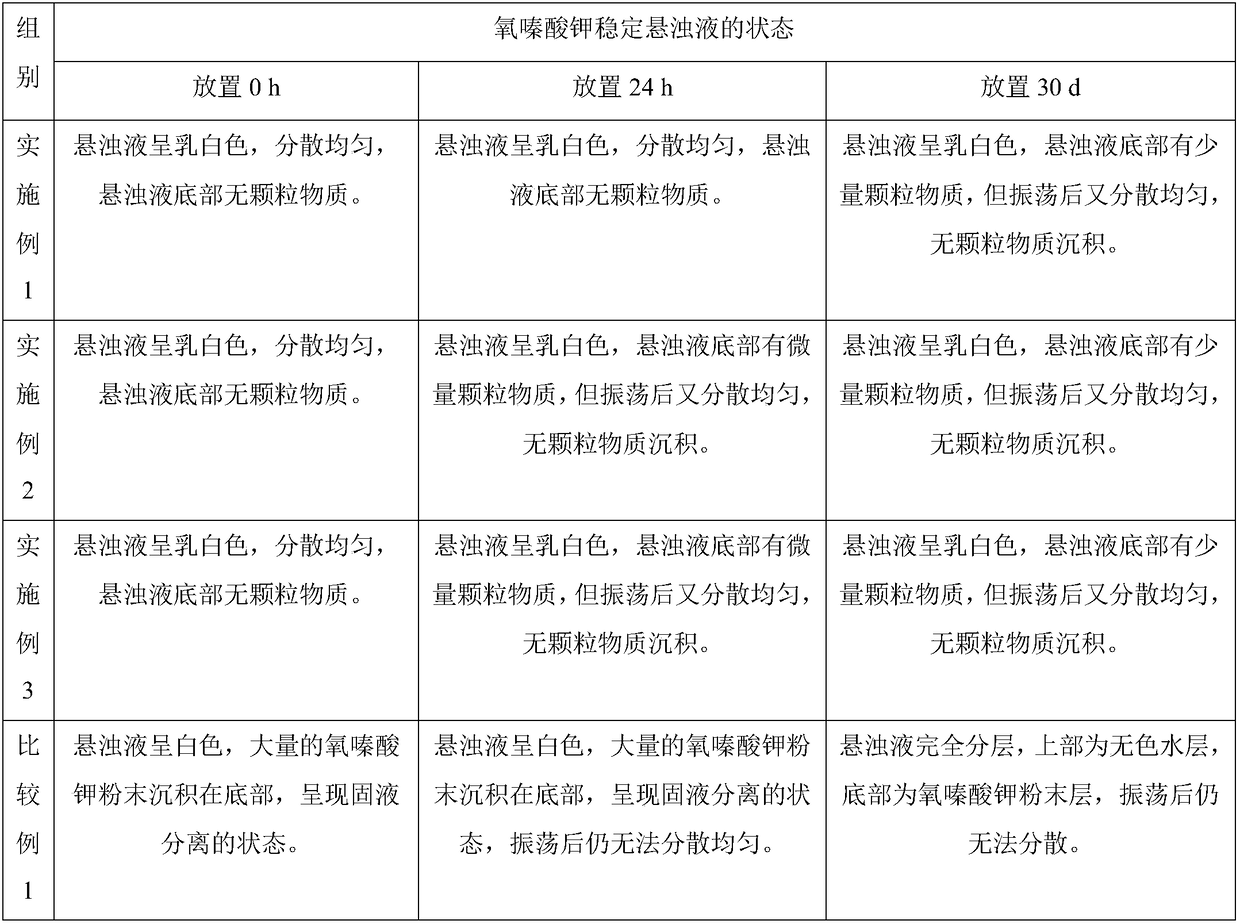

Embodiment 1

[0031] The preparation method of the potassium oxonate stable suspension comprises: taking 1 part of potassium oxonate by weight, then adding β-cyclodextrin whose weight is 2 times that of potassium oxonate, mixing evenly, and then adding zirconia balls, and then put them into the ball mill for 12 hours under the conditions of rotating speed of 500r / min and ball-to-material ratio of 5:1, take them out and pass through a 100-mesh sieve to obtain mixed fine powder of potassium dioxyxonate and β-cyclodextrin; weigh half of the The deionized water of weight part (the total weight part of deionized water is 52 parts), and adding mass ratio to deionized water is the triethanolamine, potassium carbonate and potassium hydroxide mixture of 1:2:4, stirs, obtains homogeneous solution , put the homogeneous solution in a water bath environment at 50°C, stir at a speed of 1000r / min for 30min, then add the mixed fine powder of potassium oxonate and β-cyclodextrin prepared in step 1 while stir...

Embodiment 2

[0034] The preparation method of the potassium oxonate stable suspension comprises: weighing 2 parts of potassium oxonate by weight, then adding β-cyclodextrin whose weight is 2 times that of potassium oxonate, mixing evenly, and then adding zirconia balls, and then put them into the ball mill for 12 hours under the conditions of rotating speed of 500r / min and ball-to-material ratio of 5:1, take them out and pass through a 100-mesh sieve to obtain mixed fine powder of potassium dioxyxonate and β-cyclodextrin; weigh half of the The deionized water of weight part (the total weight part of deionized water is 50 parts), and adding mass ratio to deionized water is the triethanolamine, potassium carbonate and potassium hydroxide mixture of 1:2:4, stirs, obtains homogeneous solution , put the homogeneous solution in a water bath environment at 50°C, stir at a speed of 1000r / min for 30min, then add the mixed fine powder of potassium oxonate and β-cyclodextrin prepared in step 1 while sti...

Embodiment 3

[0037] The preparation method of the potassium oxonate stable suspension comprises: weighing 3 parts of potassium oxonate by weight, then adding β-cyclodextrin whose weight is 2 times that of potassium oxonate, mixing evenly, and then adding zirconia balls, and then put them into the ball mill for 12 hours under the conditions of rotating speed of 500r / min and ball-to-material ratio of 5:1, take them out and pass through a 100-mesh sieve to obtain mixed fine powder of potassium dioxyxonate and β-cyclodextrin; weigh half of the The deionized water of parts by weight (the total parts by weight of deionized water is 60 parts), adding mass ratio to deionized water is the triethanolamine, potassium carbonate and potassium hydroxide mixture of 1:2:4, stirs, obtains homogeneous solution , put the homogeneous solution in a water bath environment at 50°C, stir at a speed of 1000r / min for 30min, then add the mixed fine powder of potassium oxonate and β-cyclodextrin prepared in step 1 whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com