VOCs recovery system using air copious cooling

A technology of recovery system and air purification system, applied in the field of high-efficiency, low-cost separation and recovery of volatile organic gases, to achieve the effects of reducing operating costs, wide adaptability and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

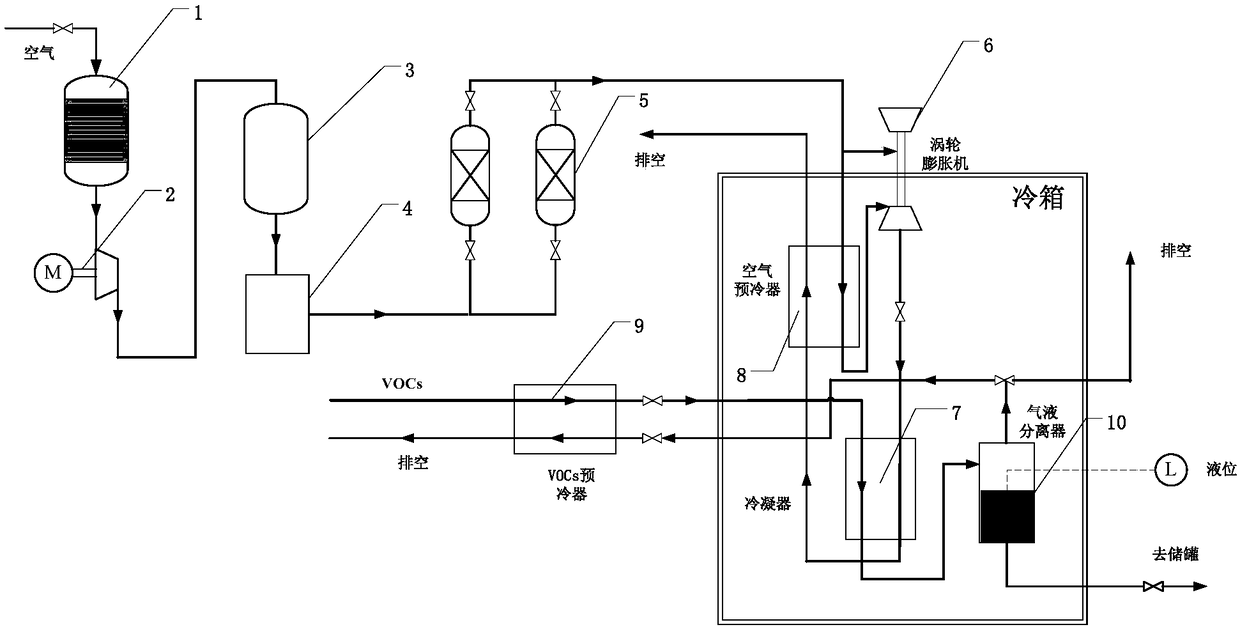

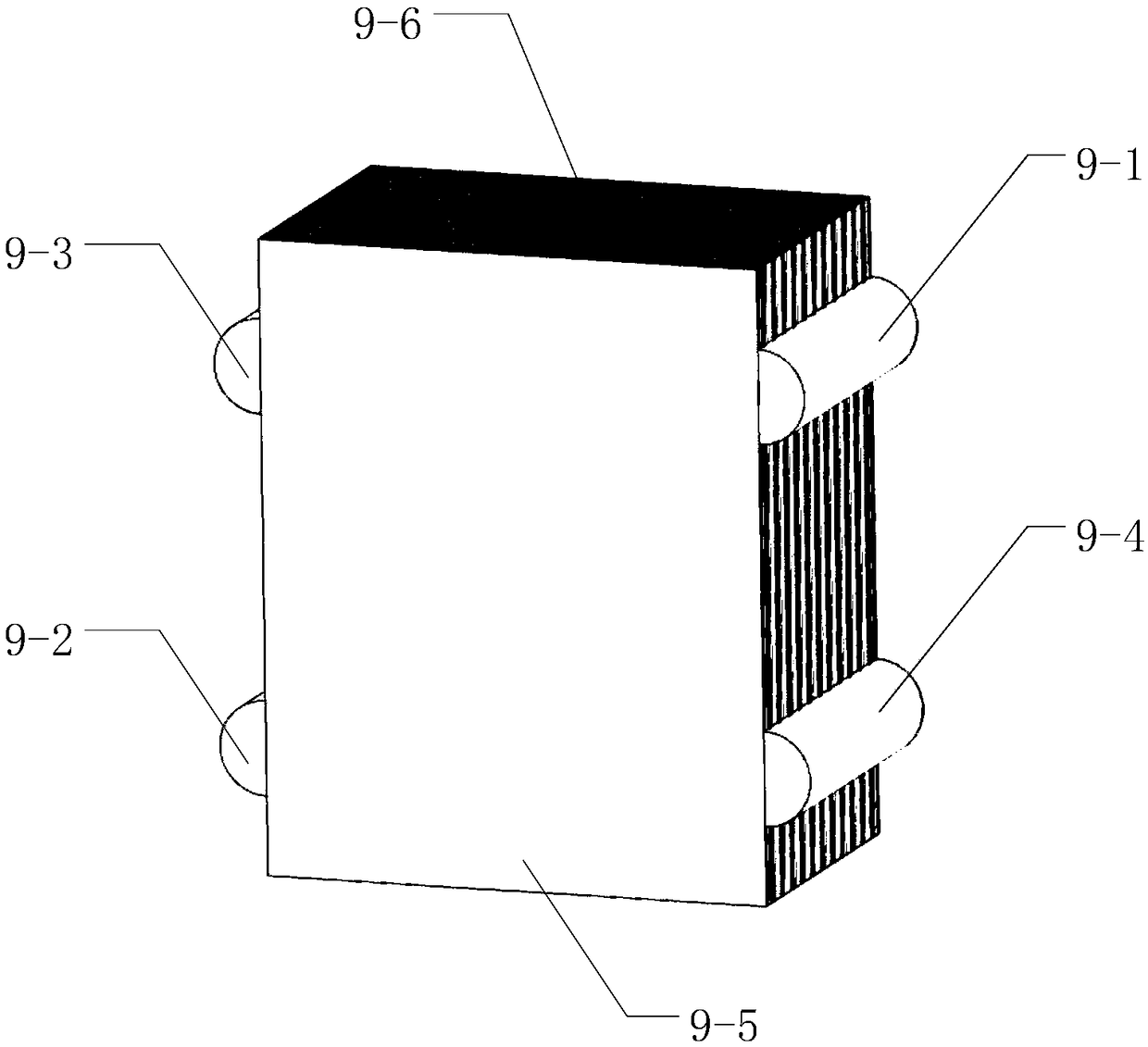

[0021] like figure 1 As shown, the VOCs recovery system includes a gaseous air purification system, an air liquefaction system and a VOCs recovery cold box. The gaseous air purification system includes an air filter 1, a cold dryer 4, and an air purifier 5; the air liquefaction system includes an air compressor 2, an air storage tank 3, a turbo expander 6, and an air precooler 8; the VOCs recovery cold box includes VOCs condenser 7, VOCs precooler 9 and gas-liquid separator 10.

[0022] When the system is working, th...

Embodiment 2

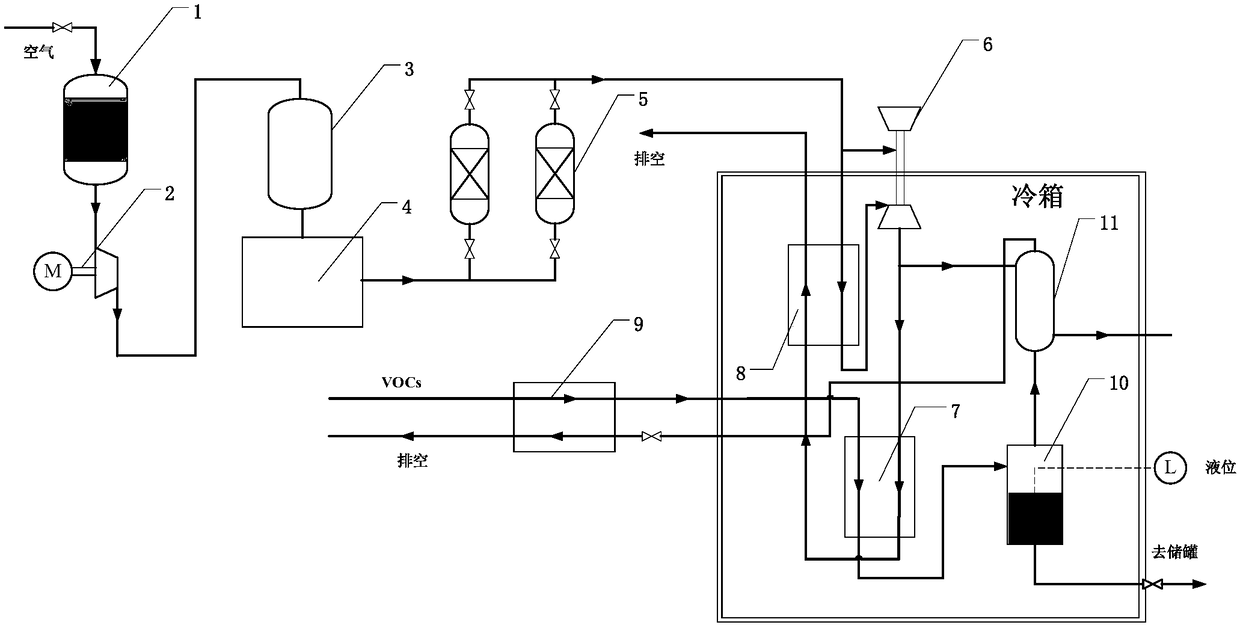

[0026] In addition to the process used in Example 1, the present invention can also further process the gas separated by the gas-liquid separator to reduce the VOCs content therein. Such as image 3 As shown, the gas flowing out of the gas-liquid separator 10 enters the microchannel mixer 11 to be directly mixed with the liquid air, the separated liquid components enter the storage tank for storage, and the low-temperature gas enters the next process. In this embodiment, the structures of the VOCs precooler and the air precooler may be the same or different, but the functions realized are different. Other equipment is the same as that in Embodiment 1, so it will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com