Concentrated microwave electrodeless ultravioletcatalysis waste gas treatment equipment

A kind of exhaust gas treatment equipment, the technology of infinite ultraviolet light, which is applied in the direction of gas treatment, chemical instruments and methods, and dispersed particle filtration, etc., can solve the problems of high cost of catalytic combustion equipment, difficult to meet the treatment effect, short residence time of exhaust gas, etc., and achieve structural Simple, reasonable design, and the effect of improving the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of the structure, change of the proportional relationship or adjustment of the size shall still fall within the scope of the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. In the range.

[0024] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present inventi...

Embodiment 1

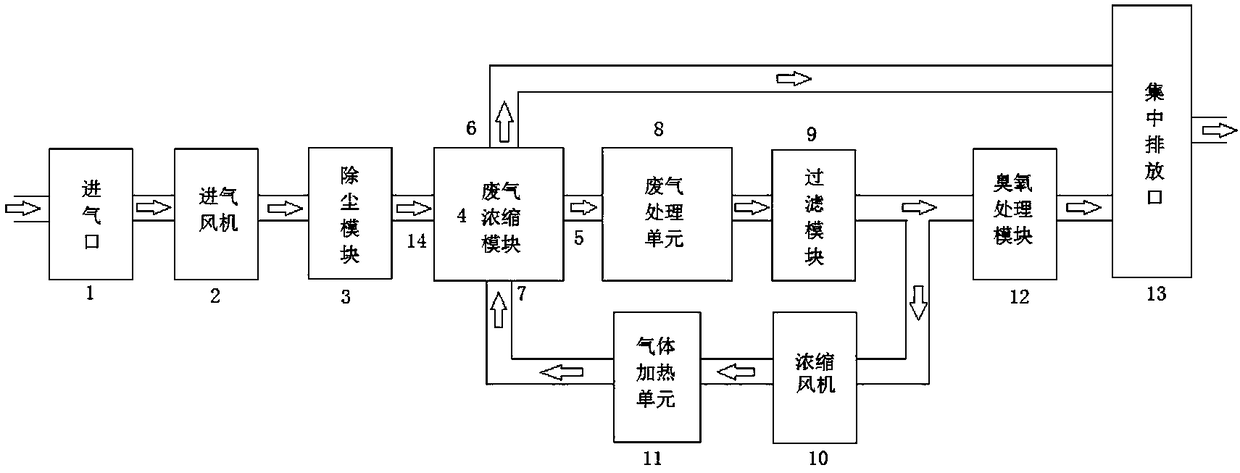

[0026] Such as figure 1 As shown, the present invention discloses a concentrated microwave stepless ultraviolet photo-oxygen catalytic exhaust gas treatment equipment, including an intake fan 2, a dust removal module 3, an exhaust gas concentration module 4, an exhaust gas treatment unit 8, a filter module 9, an ozone treatment module 12 and Concentrated discharge port 13, the output end of the air intake fan 2 is connected to the input end of the dust removal module 3, wherein the output end of the dust removal module 3 is connected to the input end of the waste gas concentration module 4, and the output ends of the waste gas concentration module 4 are respectively connected to the waste gas The input end of the processing unit 8 and the centralized discharge port 13, wherein the output end of the exhaust gas processing unit 8 is connected to the input end of the filter module 9, and the output end of the filter module 9 is connected to the input end of the ozone treatment mod...

Embodiment 2

[0036] Such as figure 1As shown, the present invention discloses a concentrated microwave stepless ultraviolet photo-oxygen catalytic waste gas treatment equipment, including an air inlet 1, an air intake fan 2, a dust removal module 3, a waste gas concentration module 4, a waste gas treatment unit 8, a filter module 9, Concentrating blower 10, gas heating unit 11, ozone treatment module 12 and centralized discharge port 13, the air inlet 1 is connected to the input end of the intake fan 2 through the air duct, wherein the output end of the intake fan 2 is connected to the dust removal module 3 The input end, wherein the output end of the dust removal module 3 is connected to the input end of the waste gas concentration module 4, and the output end of the waste gas concentration module 4 is respectively connected to the input end of the waste gas treatment unit 8 and the centralized discharge port 13, wherein the output of the waste gas treatment unit 8 terminal is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com