A sampling method for an automatic sampling manipulator used for bearing ring parts

An automatic sampling and manipulator technology, applied in the direction of manipulators, program control manipulators, furnaces, etc., can solve problems such as forgetting, missing, and unstable grasping position control, so as to avoid misoperation, save manpower and labor costs, and control accurately Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

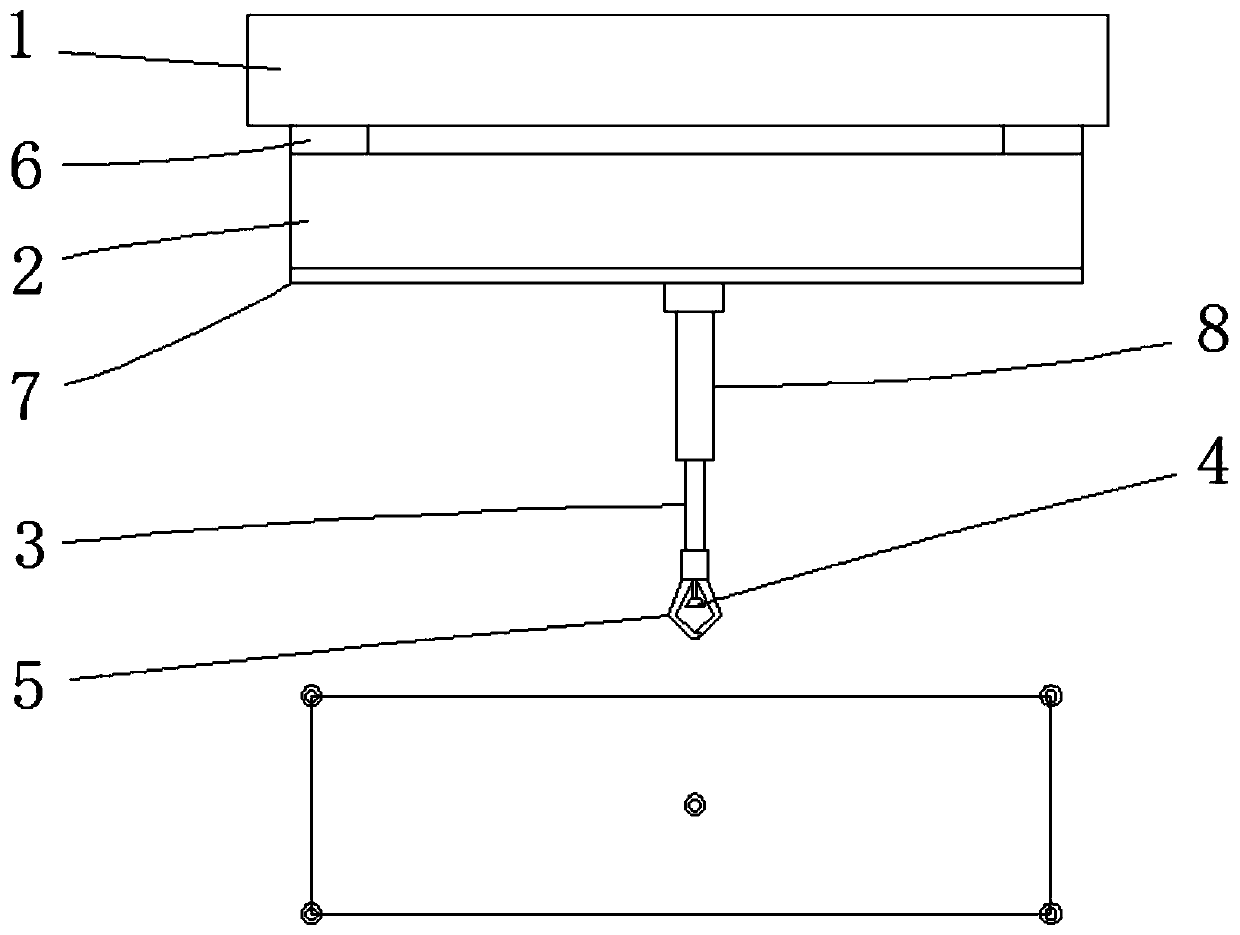

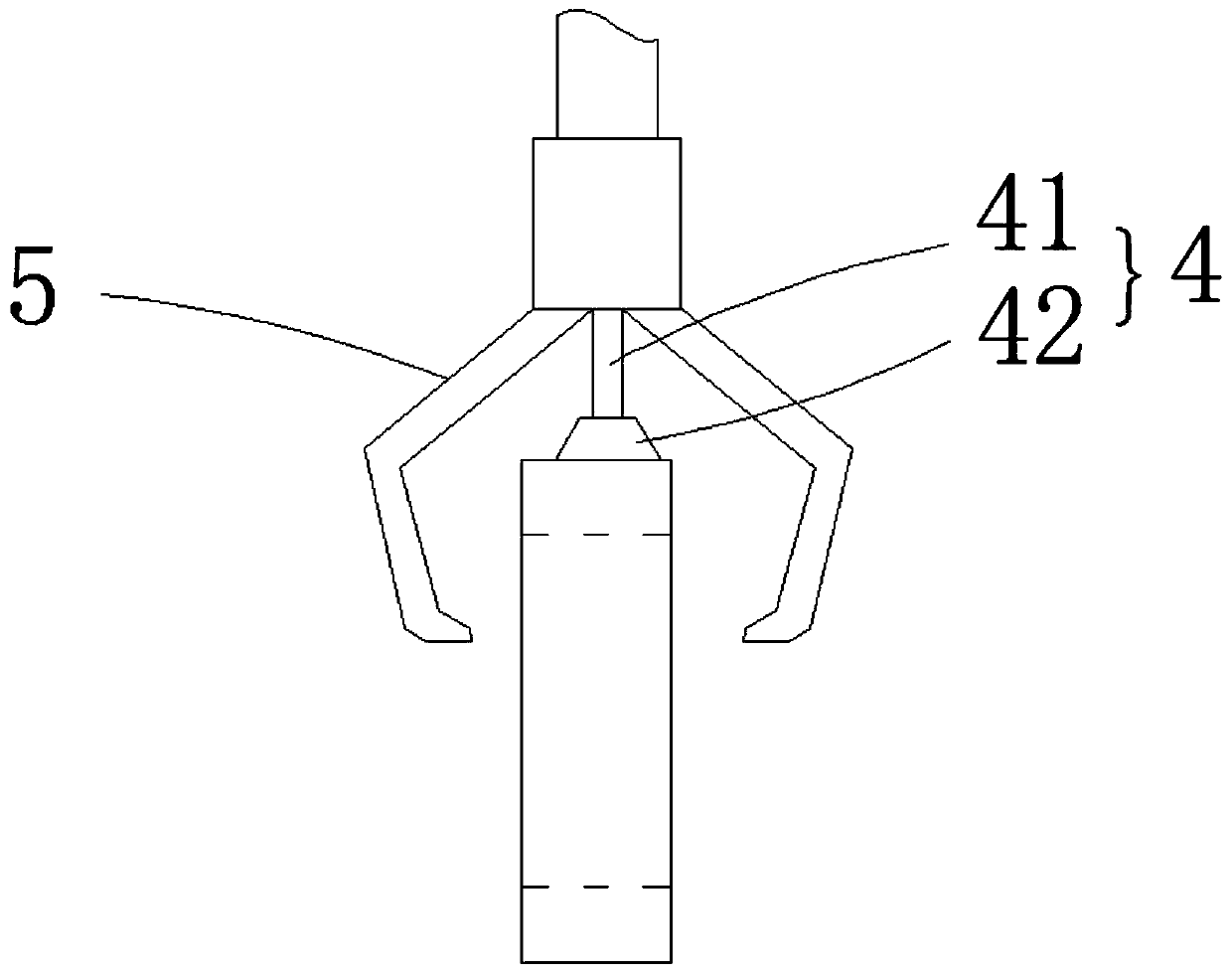

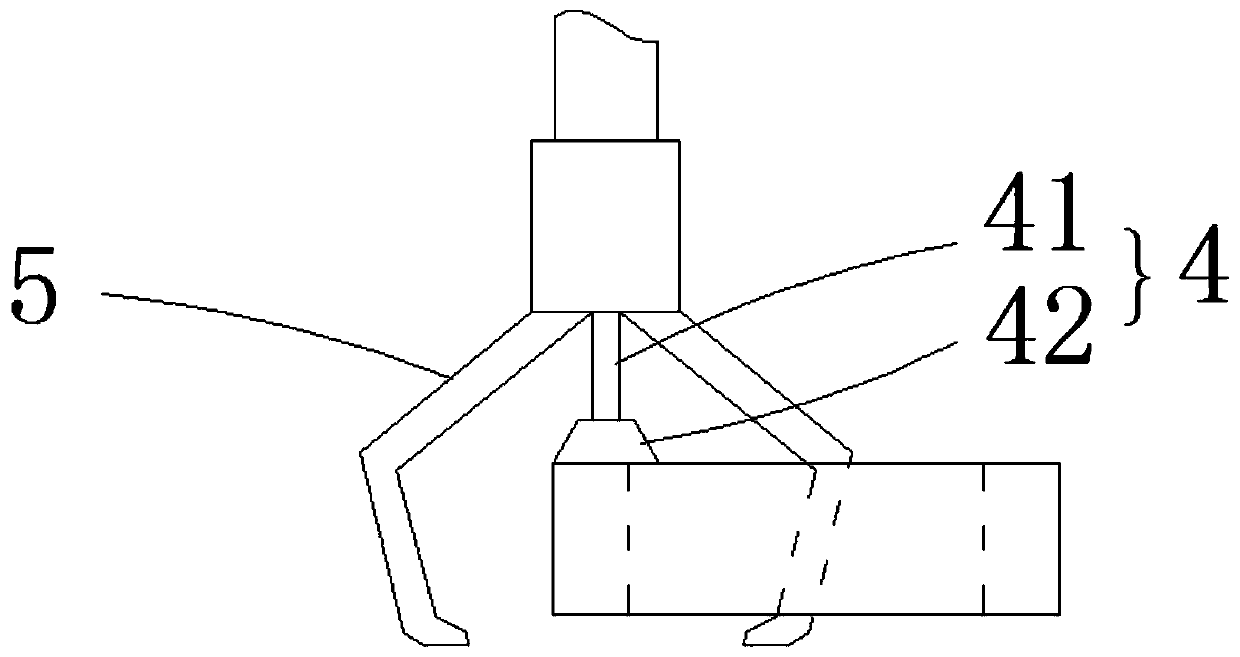

[0030] A kind of automatic sampling manipulator used for bearing ring parts of the present invention, as Figure 1 to Figure 6 As shown, it includes a control unit, a frame 1, a moving beam 2 arranged under the frame 1, a manipulator 3 arranged under the moving beam 2, a suction device 4 and a pair of grippers 5 arranged at the end of the manipulator 3; The moving beam 2 is connected to the frame 1 through the first guide rail 6 , the manipulator 3 is connected to the moving beam 2 through the second guide rail 7 , and the manipulator 3 is connected to the second guide rail 7 through the lifting device 8 .

[0031] In this embodiment, the moving beam 2 is connected with a longitudinal movement driving device, the manipulator 3 is connected with a lateral movement driving device, the lifting device 8 is connected with a lifting driving device, the longitudinal movement driving device, the lateral movement driving device and The lifting drive devices are all connected with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com