Quick temperature and pressure change device and temperature and pressure change method for high-temperature wind tunnel

A pressure-changing device and high-temperature technology, which is applied in the field of rapid temperature-variable pressure-variable devices in high-temperature wind tunnels, can solve problems such as real-time adjustment of temperature and pressure, large changes in engine flow parameters, and difficulty in predicting dynamic response of aircraft performance, etc., to achieve rapid adjustment , Avoid the linkage effect of the opening and the flow of hot and cold pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

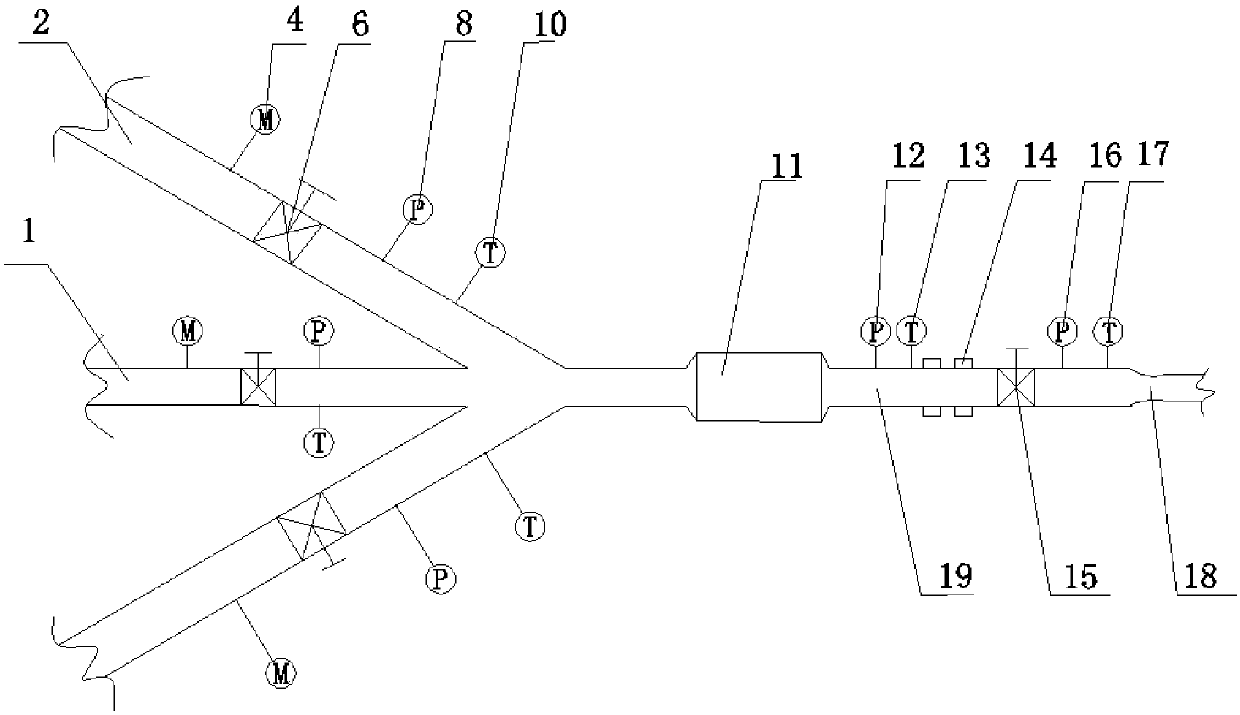

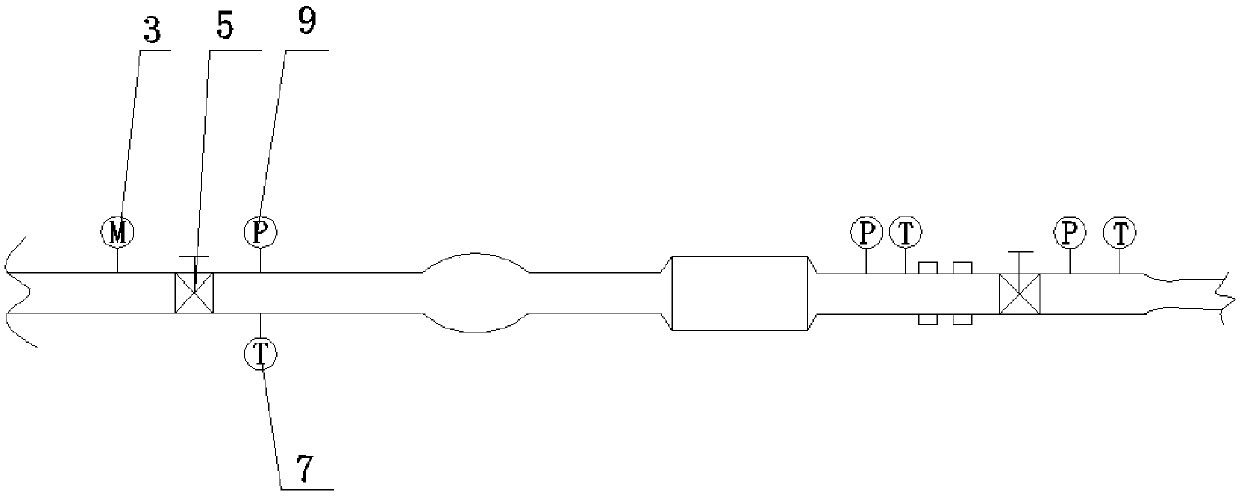

[0020] Specific embodiments one, the following will be combined with the attached Figures 1 to 3 , the present invention is described in detail:

[0021] A high-temperature wind tunnel rapid temperature and pressure changing device and a temperature and pressure changing method of the present invention include a main air intake pipe 1, an annular mixing pipe 2, a pressure stabilizing box 11 and an air outlet pipe 19, and the main air intake pipe 1 is circular and long The main intake pipe 1 and the annular blending pipe 2 are connected to one end of the surge tank 11 after confluence, and the other end of the surge tank 11 is connected to the outlet pipe 19. The main intake pipe 1 is a high-temperature hot flow gas. 2 is cold gas at normal temperature, and enters the pressure stabilizing box 11 to stabilize the pressure after merging, so as to prevent the danger from being too high. The first high temperature resistant flowmeter 3 and the first thermocouple 9, the first high...

specific Embodiment approach 2

[0022] Specific implementation mode two, the following will be combined with the attached Figures 1 to 3 , the present invention is described in detail:

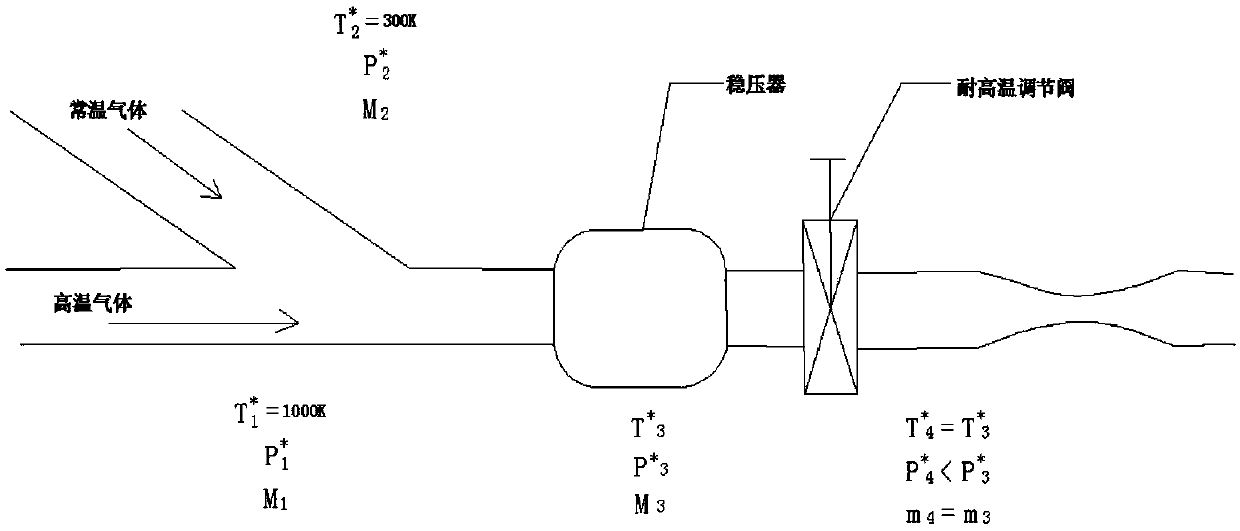

[0023] A method for rapidly changing temperature and pressure in a high-temperature wind tunnel, characterized in that it comprises the following steps:

[0024] Step 1. Collect data on the total temperature and total pressure of the hot air in the main pipeline;

[0025] In the high-temperature hot air main pipeline 1, the high-temperature air flows through the first high-temperature-resistant flowmeter 3 for flow measurement, and after being regulated by the high-temperature-resistant flow regulating valve 5, the first high-temperature-resistant total pressure probe 7 and the first thermocouple are used to measure the flow rate. 9. Carry out data collection of total temperature and total pressure respectively;

[0026] Step 2, collecting the total temperature and total pressure data of the cooling air flow in the annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com