Preparation process of large titanium alloy air inlet for missiles

A technology for preparation process and air intake channel, which is applied in the field of titanium alloy casting, can solve problems such as easy deformation of castings, cracks that cannot be quickly removed in a closed structure, and cracks formed on the surface of the inner cavity of the air intake channel, so as to ensure complete mold filling and process The method is novel and the effect is feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

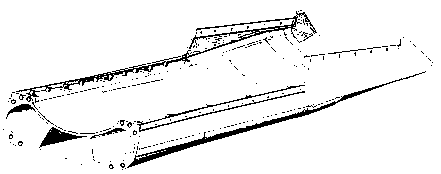

[0026] Large-scale thin-walled inlet castings for air-to-ground missiles (overall size: 365×189×1965mm, about 65% of the casting area is 3mm thin-walled structure, see figure 1 ) development process as an example.

[0027] A method for preparing a large-scale titanium alloy inlet for missiles, comprising the following steps:

[0028] Step 1. Inlet split structure design: According to the structural characteristics of the large titanium alloy air inlet for the missile, the partition of the large titanium alloy air inlet for the missile is divided into a main body and a piece, such as Figure 2-3 , the abdominal cover plate of the air inlet is a sheet body, and the rest are the body. After the division, the body and the sheet body are both open structures, which realizes the realization of the post-processing process of titanium alloy casting. The body and the sheet body are both open structures, which is conducive to the Realization of post-casting treatment process;

[0029]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com