Compression resistance and tensile force integral testing device and method thereof for electromagnet

A test device, electromagnet technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instruments, etc., can solve the problems of inaccurate sensor measurement data, cumbersome operation process, affecting service life, etc., to achieve convenience Subsequent tests, convenient operation, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

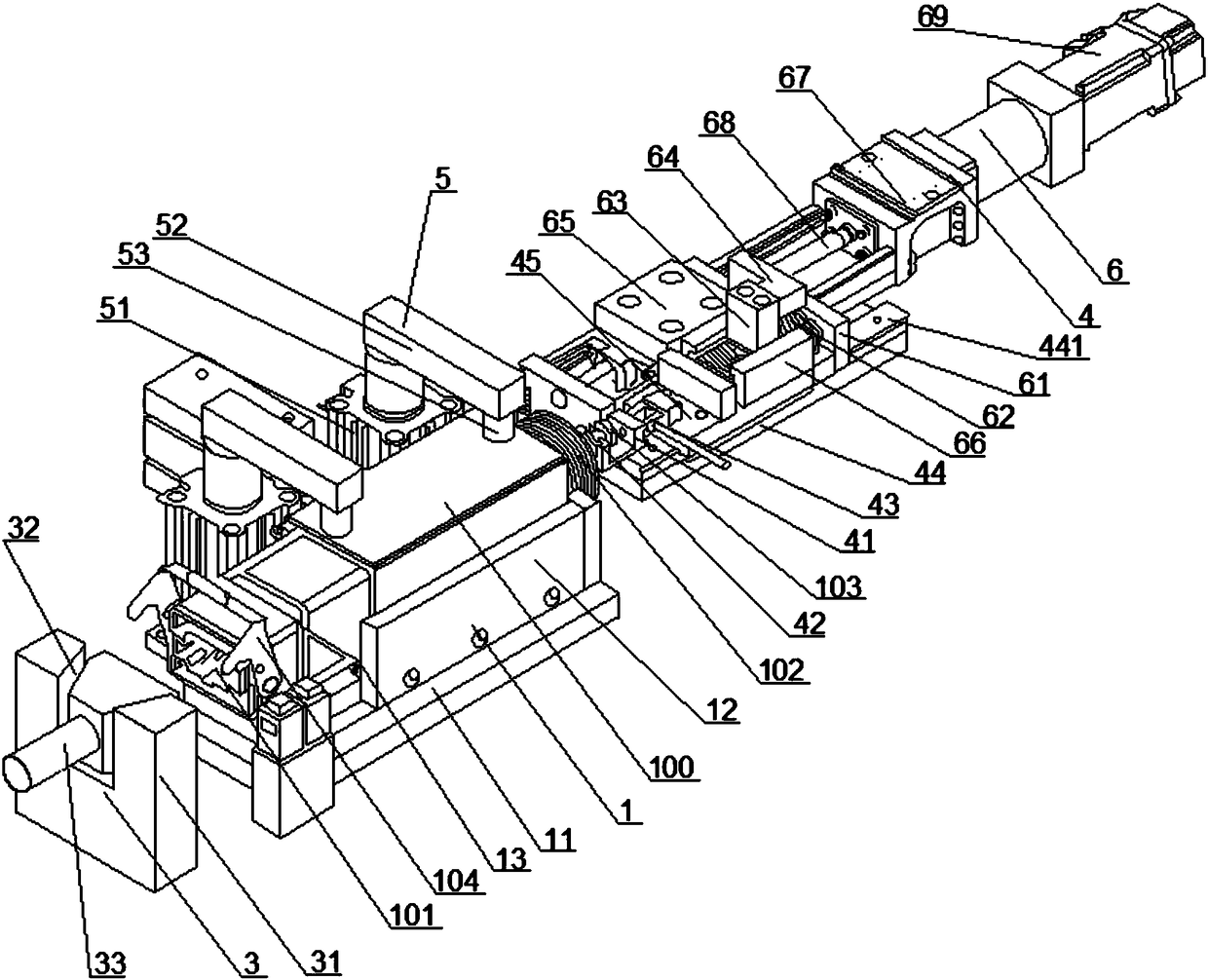

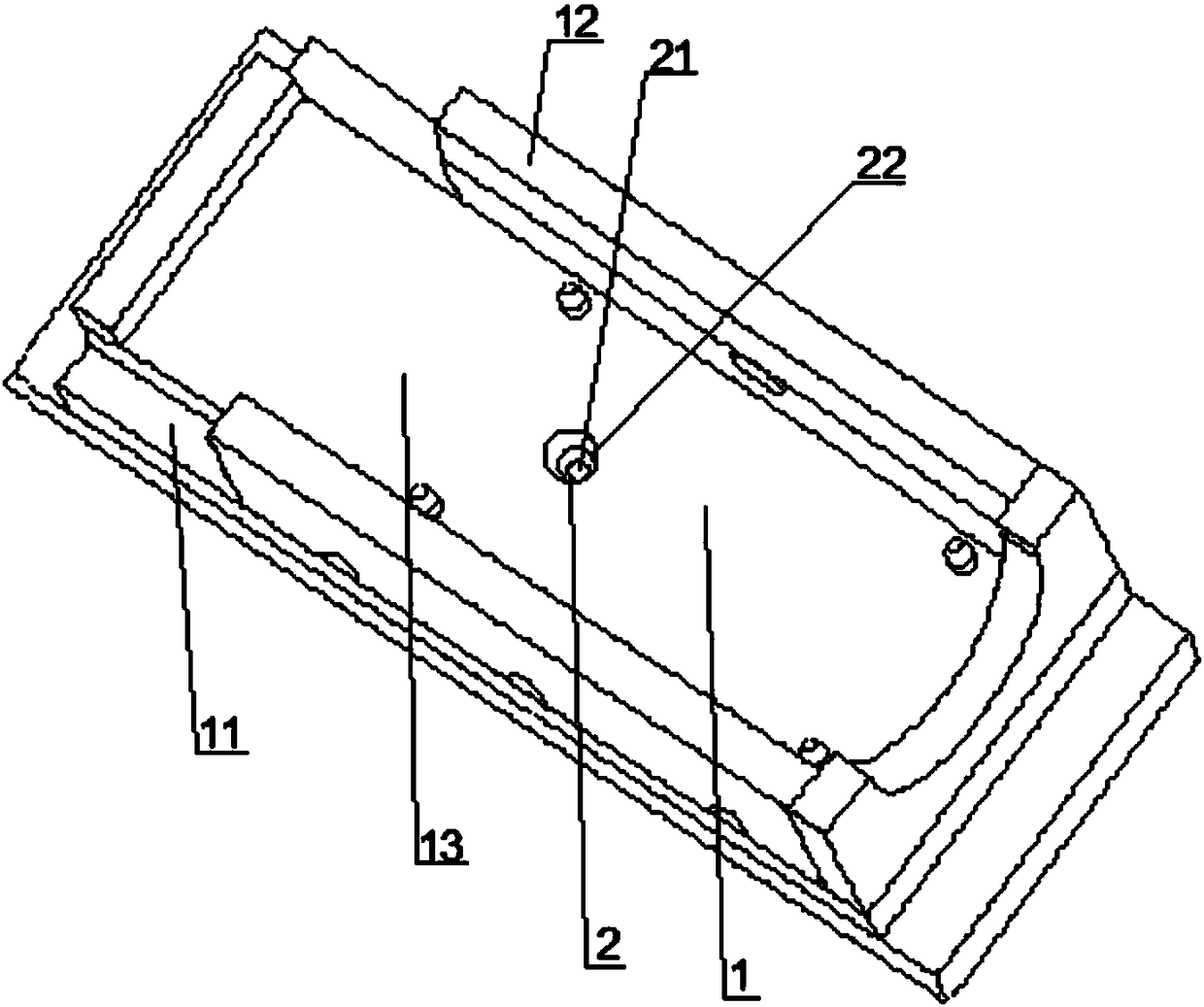

[0031] Such as Figure 1 to Figure 2 As shown, the present invention discloses an electromagnet compression and tension integrated testing device, the electromagnet at least includes a body 100, one end of the body 100 is provided with a connector 101 electrically connected to its internal coil, and the other end is provided with a A connecting head 102 that can move horizontally relative to it, and a bolt 103 is fixed on the connecting head 102 . Wherein, the body 100 is provided with a coil (not shown in the figure), and the piston (not shown in the figure) inside the coil will generate magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com