Temperature controlled ion source

An ion source and ion beam technology, applied in the field of ion sources, can solve problems such as ion source operation or adverse effects on lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments are described herein in conjunction with an indirectly heated cathode (IHC) ion source. However, other ion sources such as Bernas and Freeman ion sources or RF ion sources may be used. Therefore, the present invention is not limited to the specific examples set forth below.

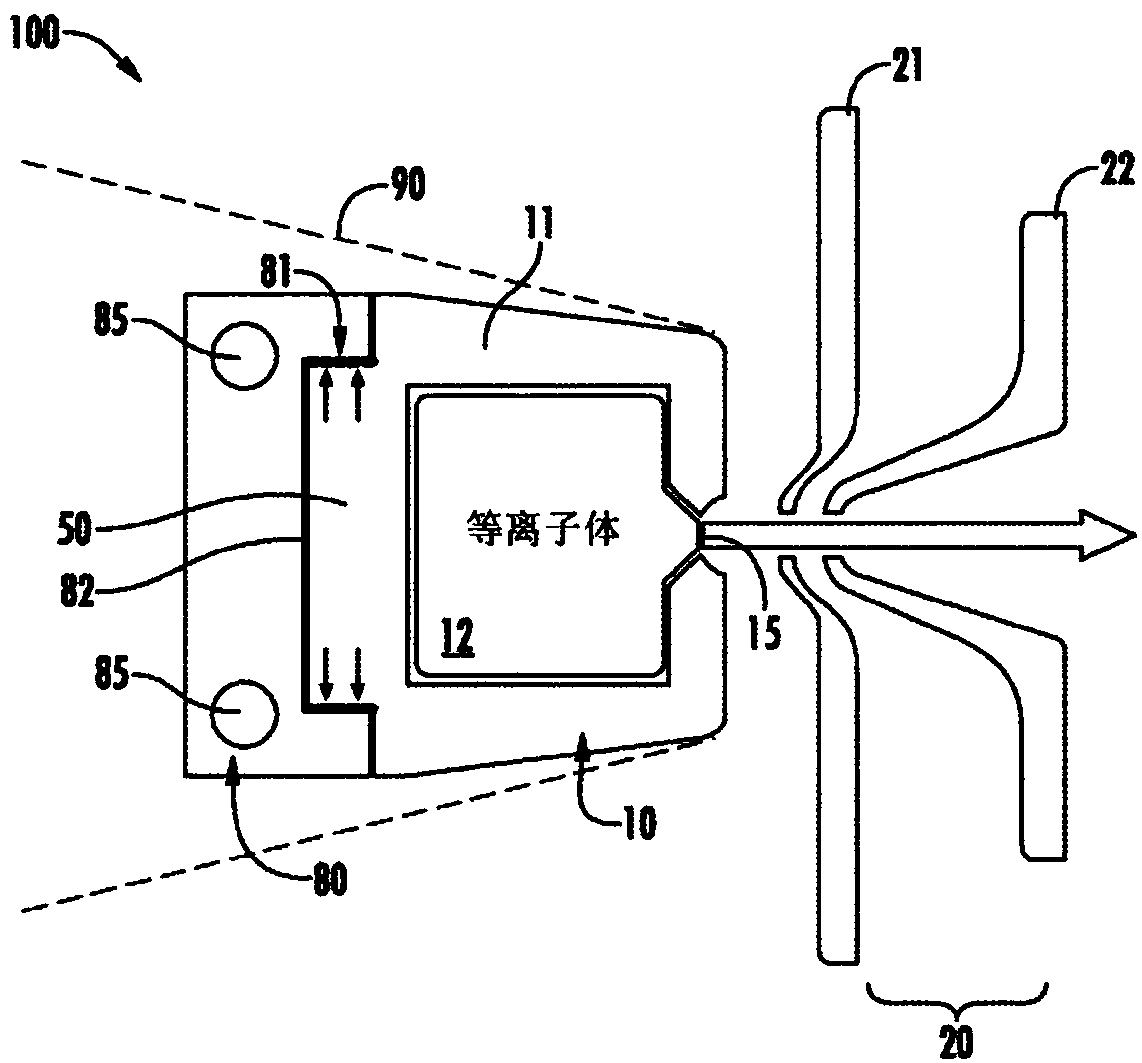

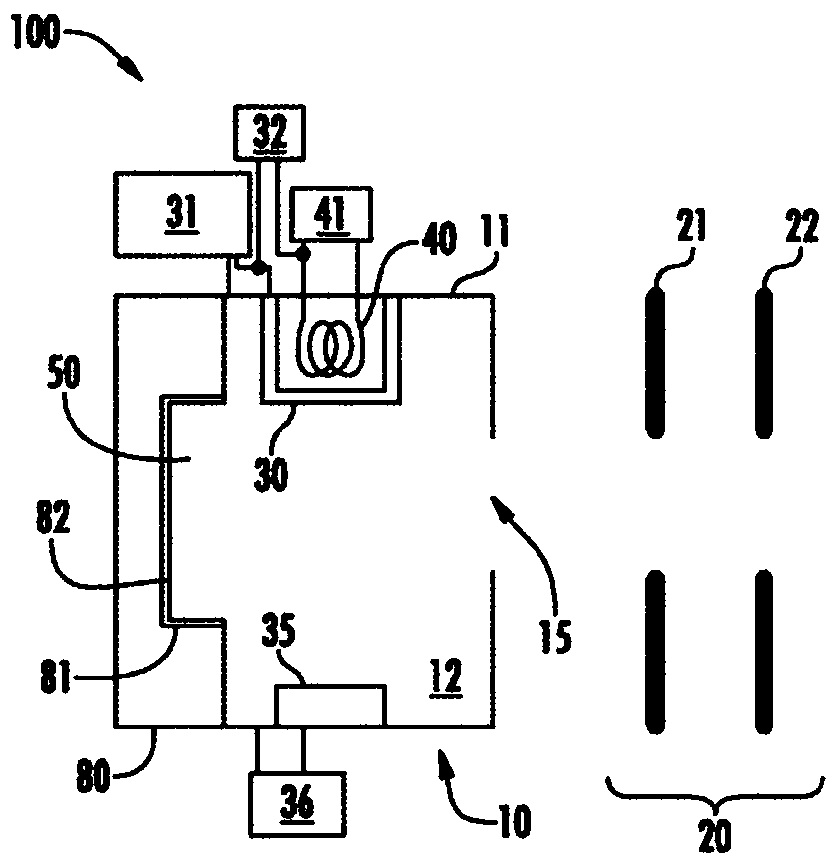

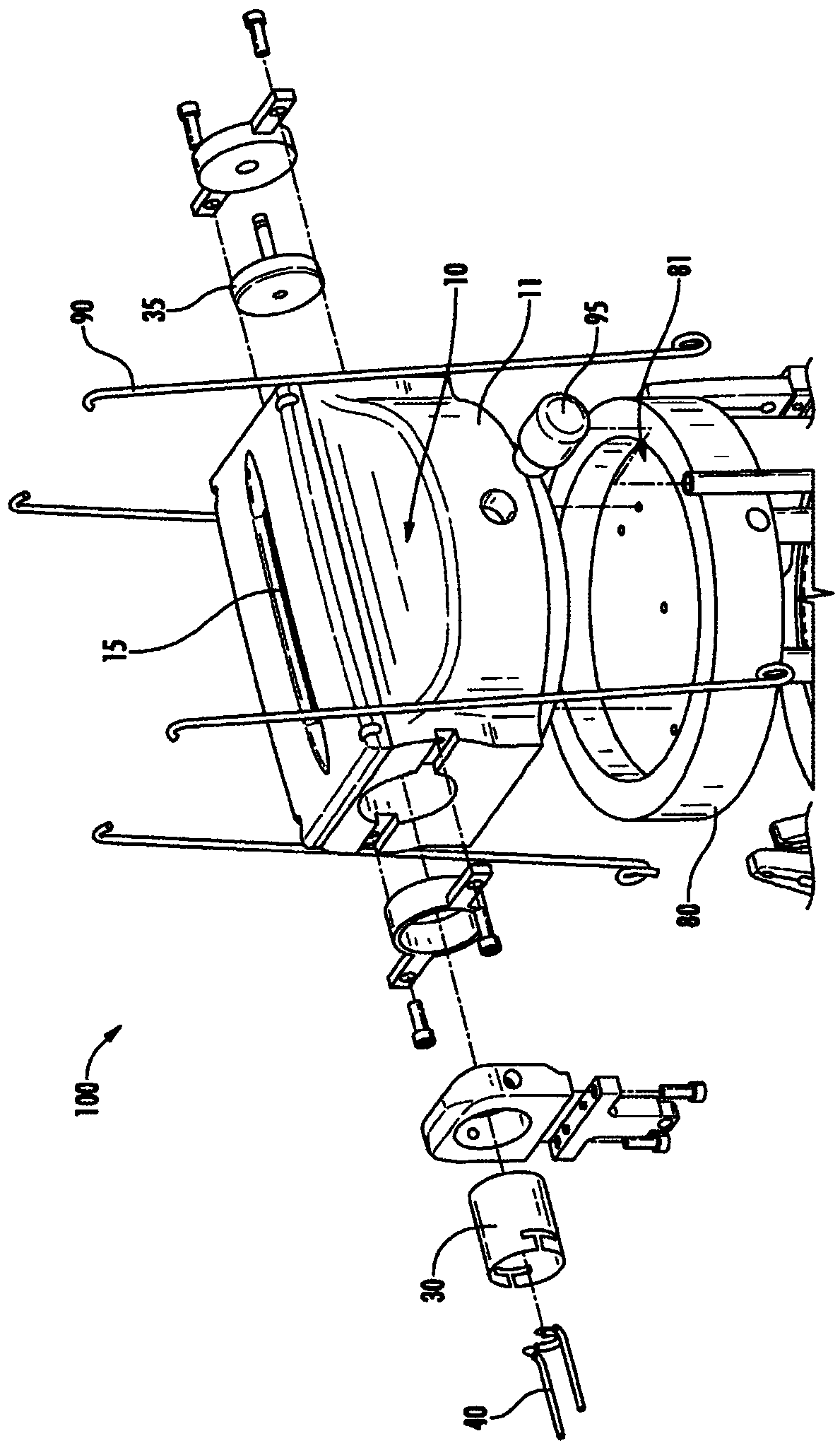

[0021] figure 1 A representative apparatus 100 that may be used to generate an ion beam is shown. The apparatus 100 includes an ion source 10 and a heat sink 80 . Ion source 10 may be an indirectly heated cathode (IHC) ion source, although other ion sources may also be used. Ion source 10 has a plurality of chamber walls 11 that define an ion source chamber 12 . The chamber wall 11 may be constructed from an electrically conductive material. One of the chamber walls has an extraction aperture 15 through which ions can be extracted from the ion source chamber 12 . Outside the ion source chamber 12 and near the extraction aperture 15 there are one or more electrodes 20 . In certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com