Factory-style environmentally friendly intelligent high-efficiency crushed stone sand production process

A production process and environmental protection technology, applied in the direction of grain processing, etc., can solve the problems of many hidden dangers, waste of ore resources, pollution of the atmospheric environment, etc., and achieve the effect of ensuring the quality of infrastructure projects, avoiding hidden dangers, and avoiding environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings and embodiments.

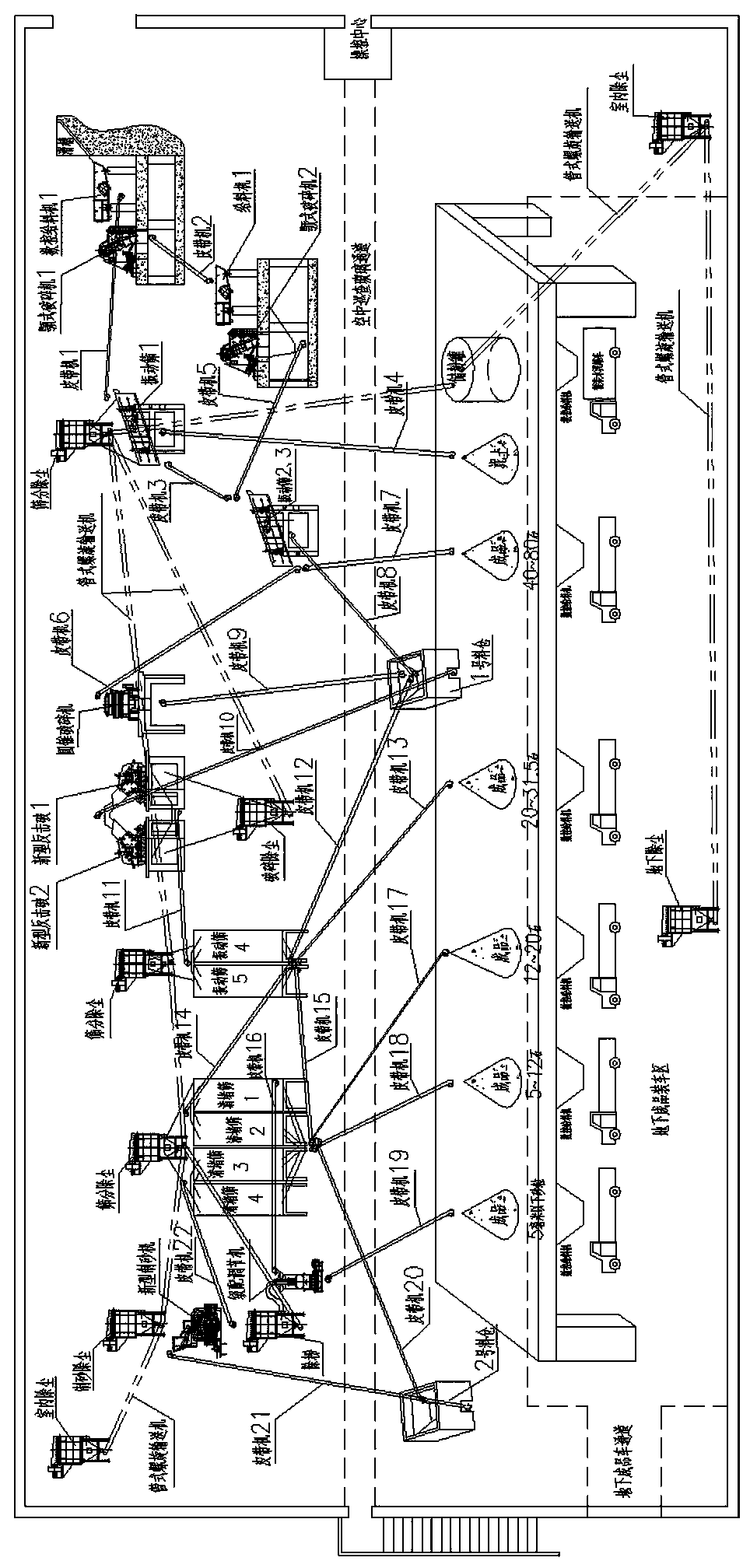

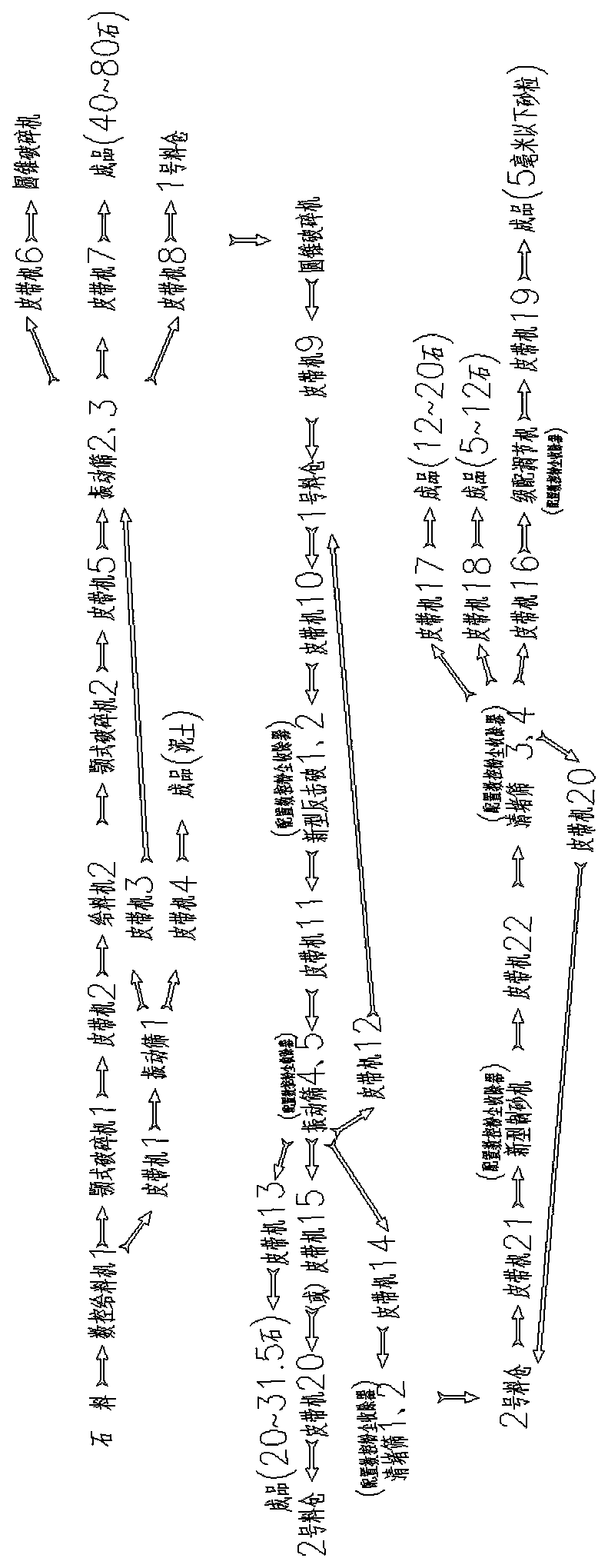

[0017] see figure 1 and figure 2 , a factory-type environmentally friendly, intelligent and efficient crushed stone sand production process, which is divided into large stone crushing, medium stone crushing and continuous grading adjustment process of sand making and finished sand;

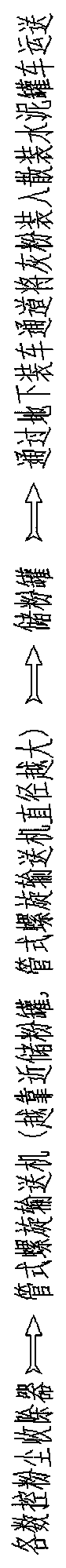

[0018] The stone enters the CNC feeder 1, the CNC feeder 1 sends the large stone to the jaw crusher 1, and the small stone and soil are sent to the vibrating screen 1 through the belt conveyor 1. The soil is sent to the vibrating screen 2 and the vibrating screen 3 through the belt conveyor 3, in which the soil is sent to the finished product silo through the belt conveyor 4; the jaw crusher 1 crushes the large stones and sends them to the feeder 2 through the belt conveyor 2. The machine 2 sends the larger stone into the jaw crusher 2, and the smaller stone and the crushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com