Metal cutting machine tool convenient to adjust

A metal cutting and machine tool technology, applied in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of metal chips not being processed in time, inconvenient adjustment of metal cutting machines, and reducing metal cutting quality. The effect of improving cutting quality, avoiding offset, and facilitating cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

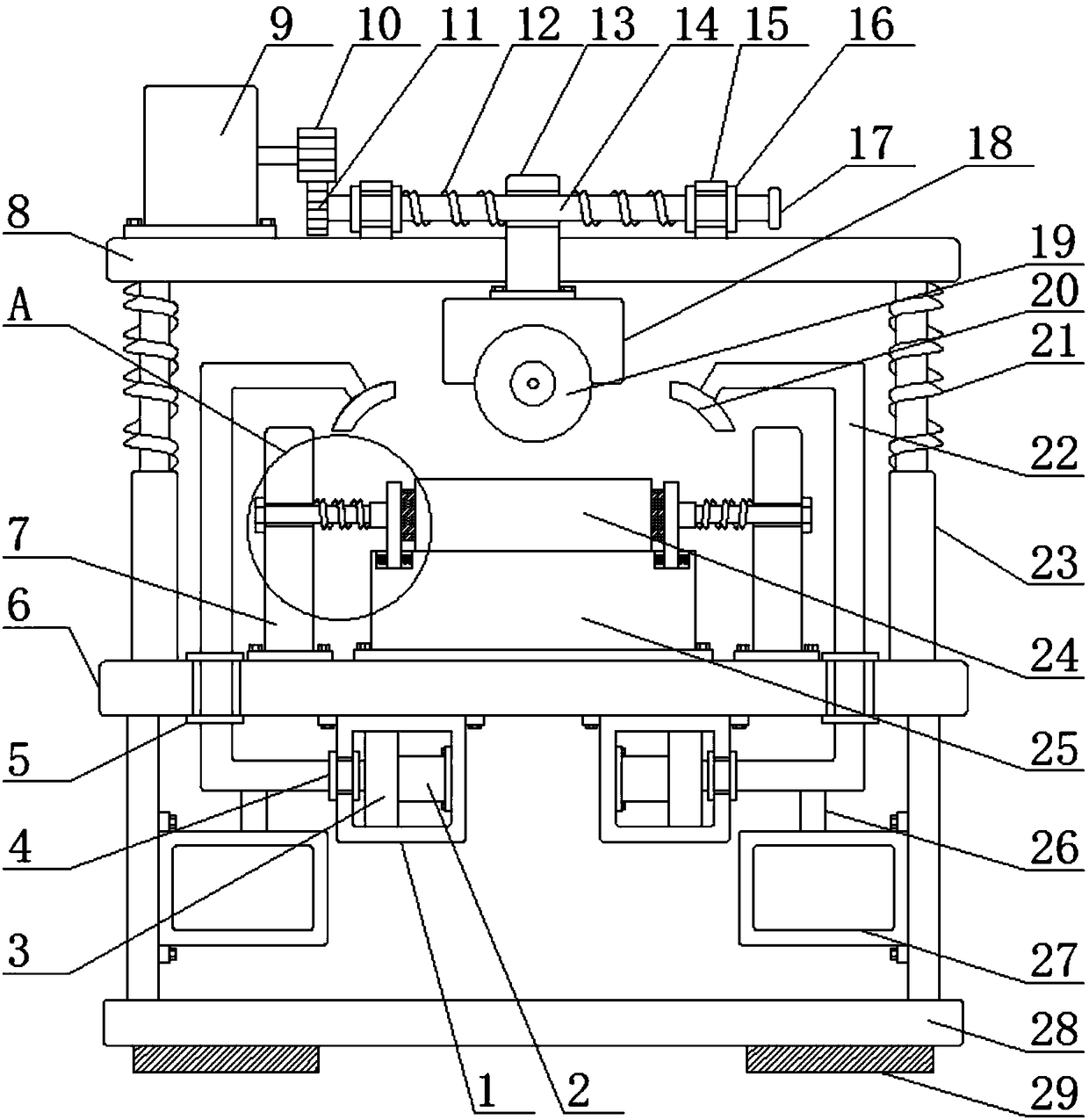

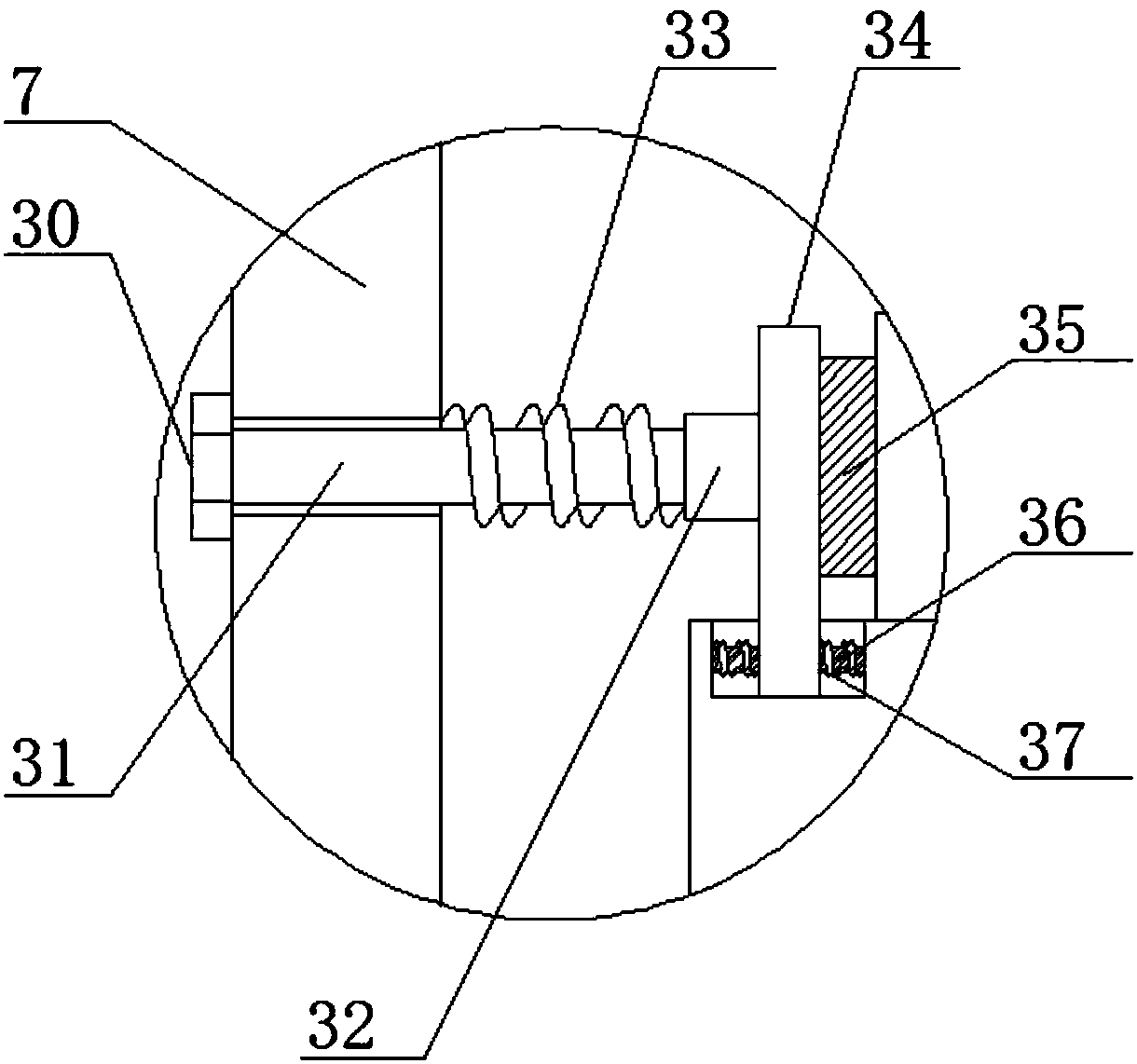

[0030] refer to Figure 1-2 , a conveniently adjustable metal cutting machine tool, including a base 28, a placement platform 6 is arranged above the base 28, two support plates are symmetrically arranged between the placement platform 6 and the base 28, and the opposite side walls of the two support plates are provided with A storage box 27 is fixed, and two driving boxes 1 are symmetrically fixed on the lower end of the placing table 6. The first driving motor 2 is fixed in the driving box 1, and the end of the output shaft of the first driving motor 2 is connected with a turbo blower 3. The suction port of the fan 3 is connected with a suction pipe 22, and the end of the suction pipe 22 away from the turbo blower 3 runs through the drive box 1 and the placement table 6 and is connected with a suction hood 20, and the suction pipe 22 and the storage box 27 pass through The connecting pipe 26 is connected, and the metal debris produced in the cutting process is driven by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com