Food can airtightness automatic detection system for canned food

A technology for canned food and automatic detection, which is used in packaging food, automatic packaging control, liquid tightness measurement using liquid/vacuum degree, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

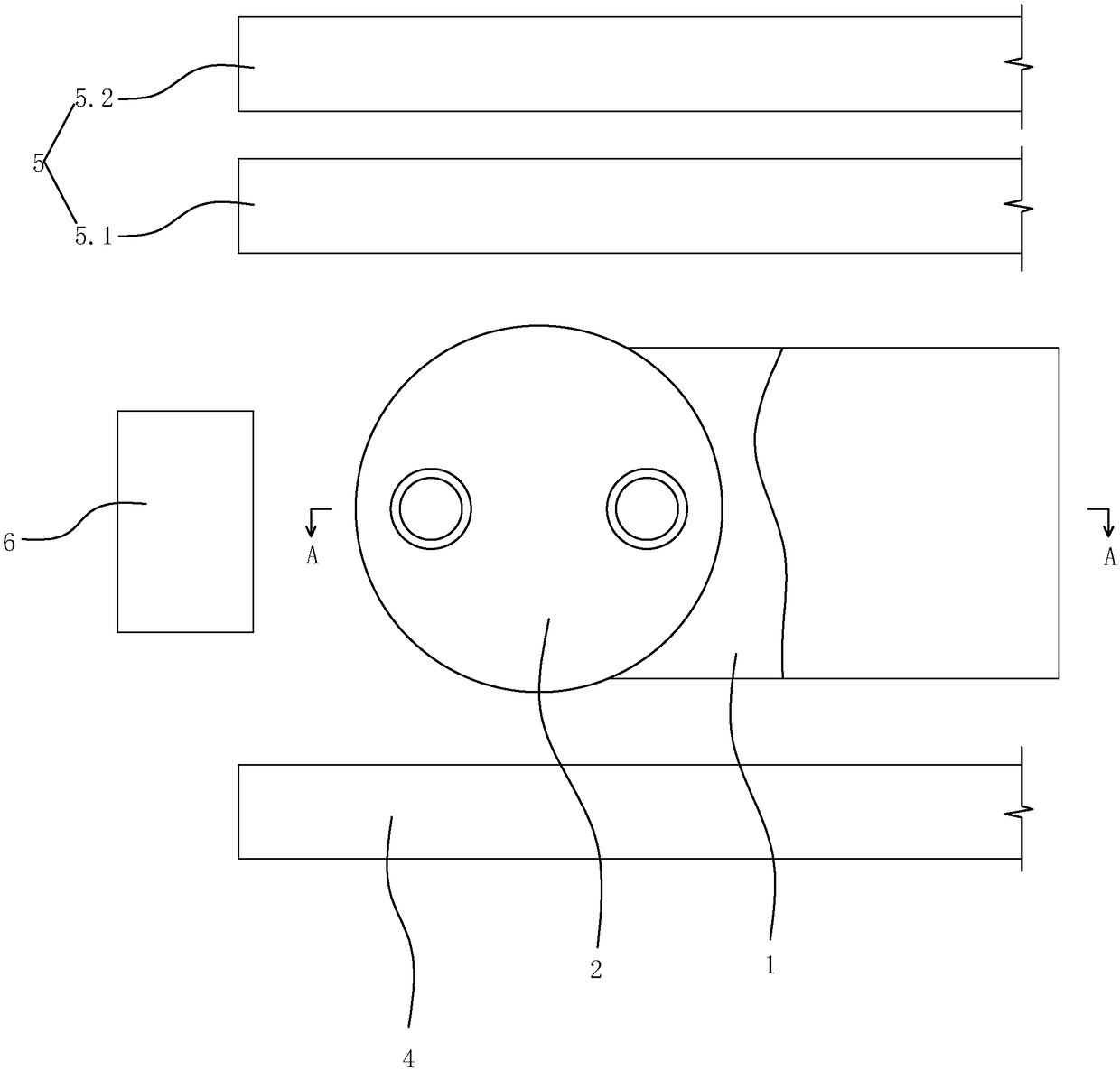

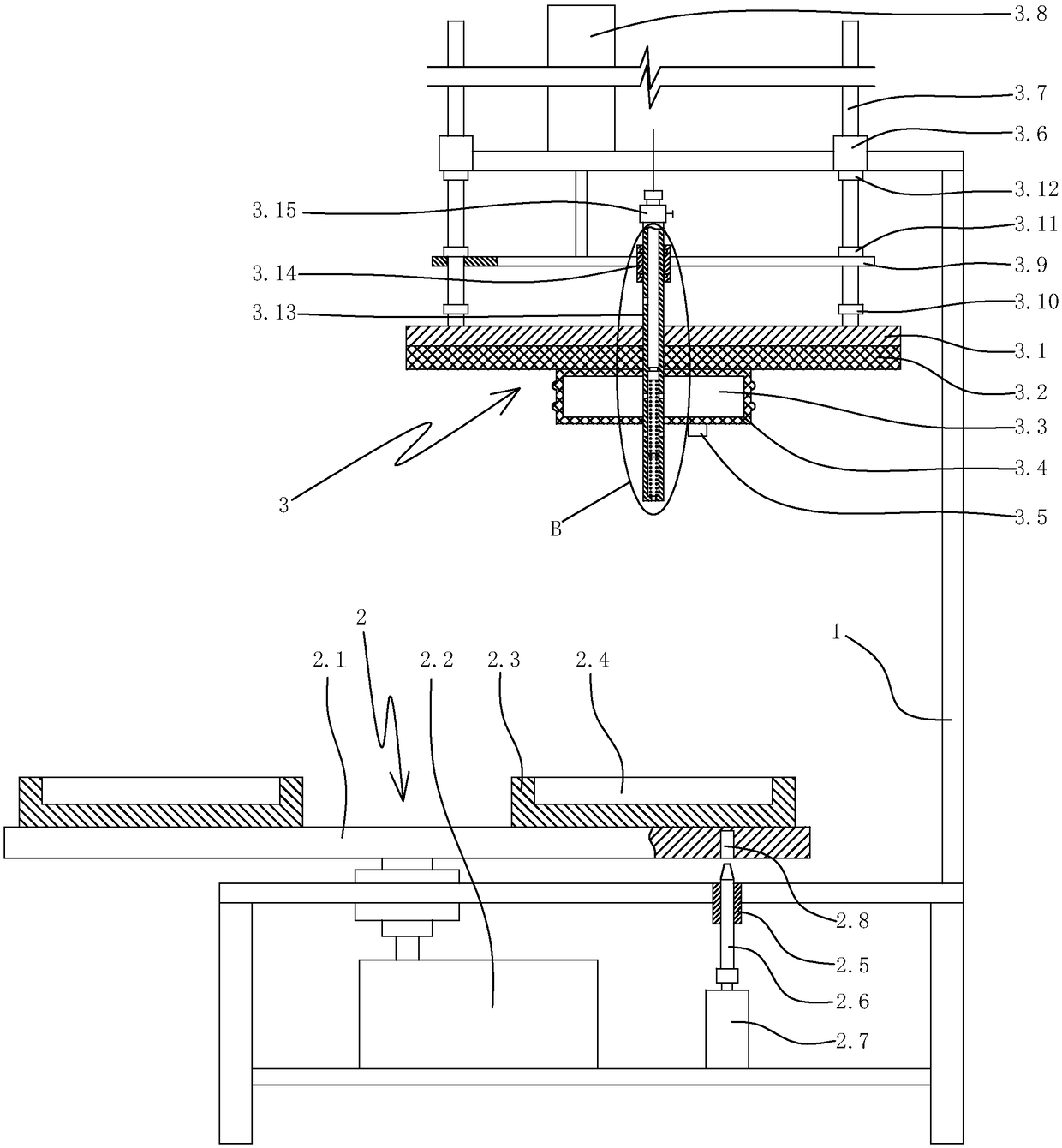

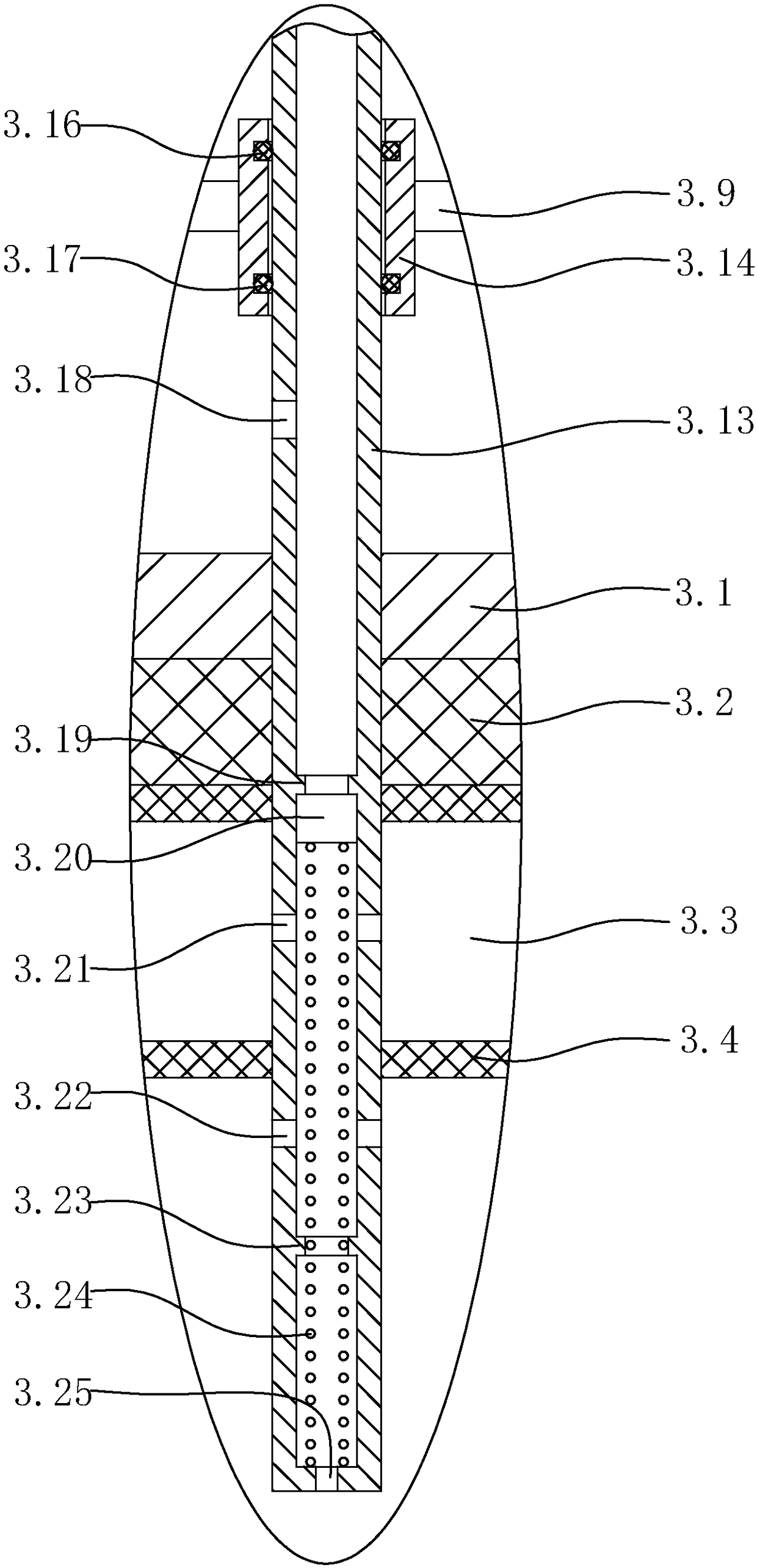

[0029] Such as figure 1 As shown, an automatic detection system for food can air tightness of canned food, including a frame 1, a food can positioning mechanism 2, an air tightness detection device 3, a food can feeding conveyor belt 4, and a food can discharging conveyor belt 5 and manipulator 6.

[0030] Such as figure 1 , figure 2 As shown, the food can positioning mechanism includes a turntable 2.1 installed on the frame through the rotation of the vertical shaft, a rotating motor 2.2 for driving the turntable to rotate, a turntable positioning mechanism, and a number of positions arranged on the upper surface of the turntable and around the vertical shaft. Position the seat 2.3 toward the evenly distributed food jars.

[0031] There are two food jar positioning seats in this embodiment. The upper surface of the food can positioning se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com