Bag type spiral-wound combined bubble-free aeration device

A non-bubble aeration and bag-type technology, applied in biological treatment devices, special treatment targets, water/sludge/sewage treatment, etc., can solve the problem of small hollow fiber bundles, high frequency of gas exchange, easy blockage of biofilm, etc. Problems, to achieve the effects of not easy to block, less wind resistance, and less power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The content of the present invention will be described below in conjunction with specific embodiments.

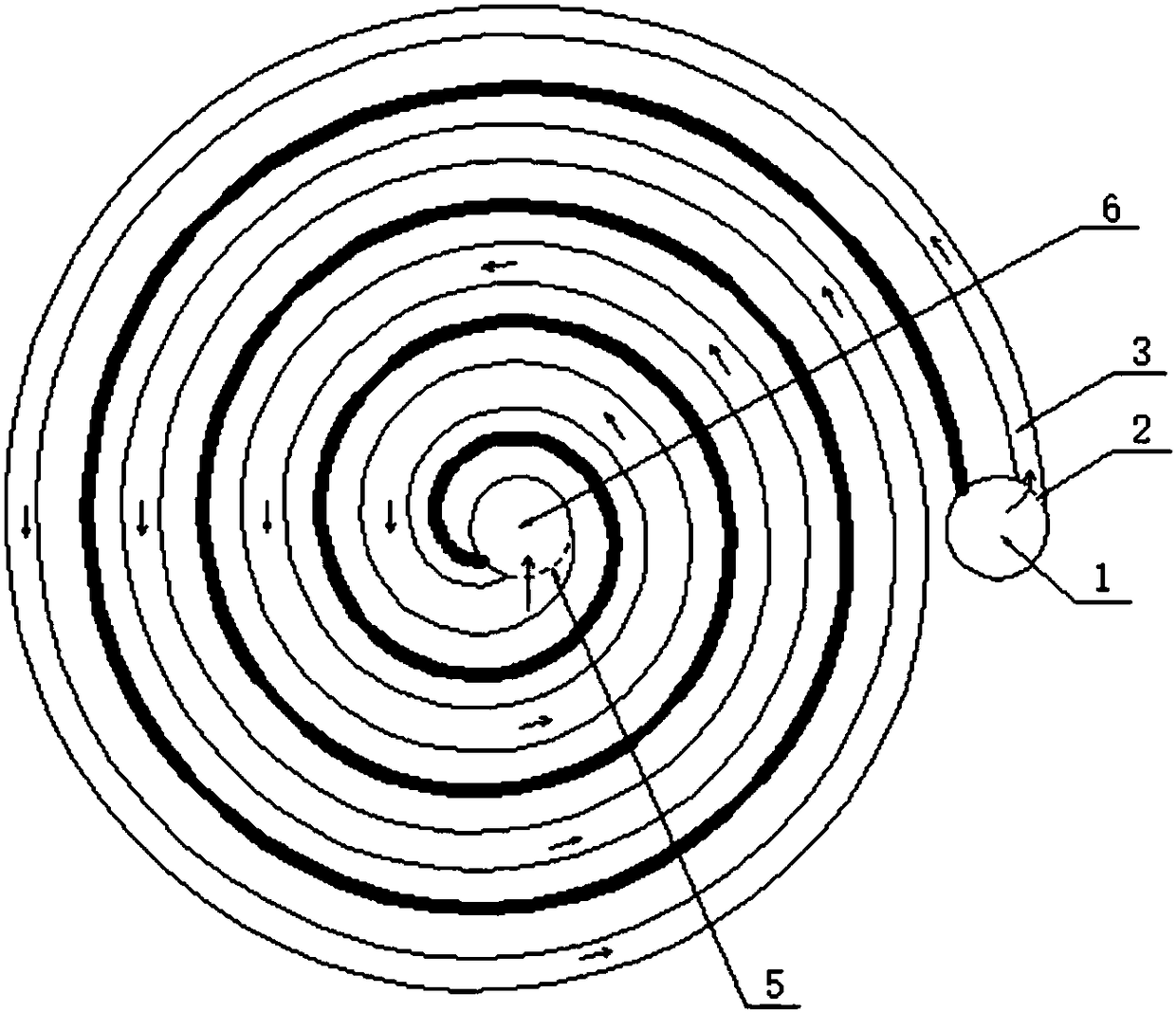

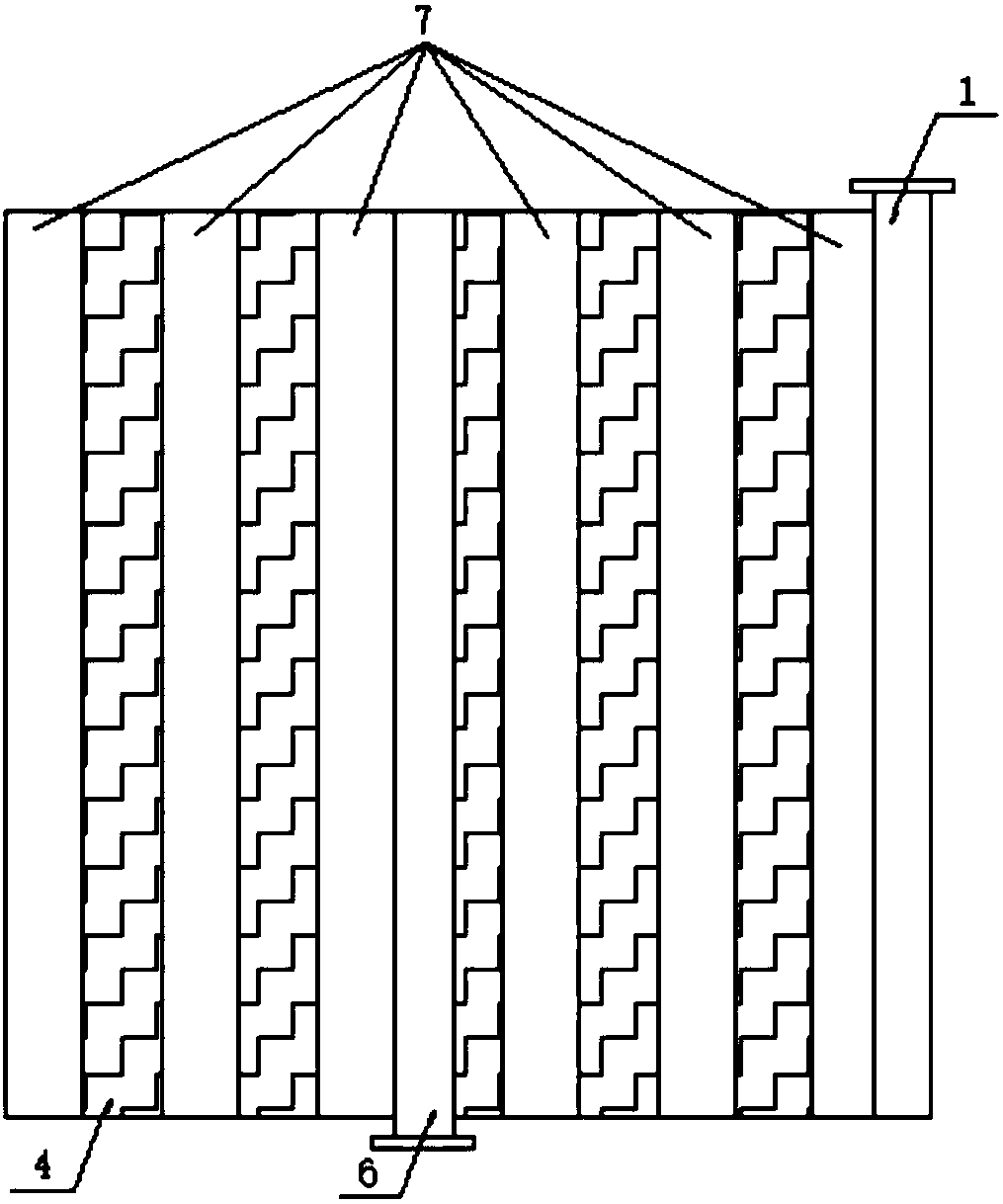

[0016] Such as Figure 1 to Figure 3 As shown, it is a structural schematic diagram of a bag-type spiral-wound combined non-bubble aeration device according to the present invention.

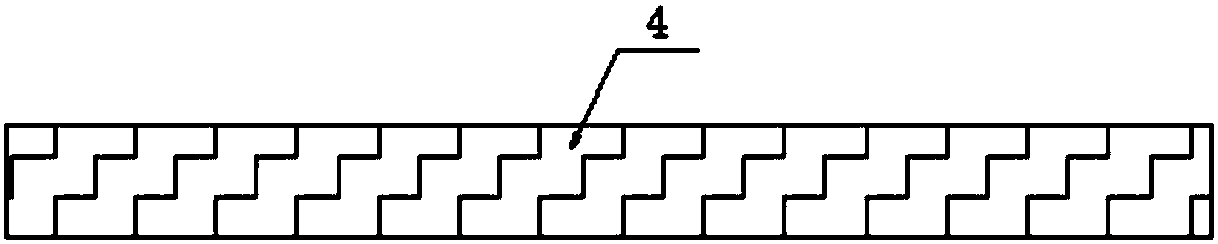

[0017] The bubble-free aeration device of the bag-type spiral-wound combination according to the present invention includes a double-layer bag-type air hypertonic biofilm 3, and the front and rear ends of the double-layer bag-type air hypertonic biofilm 3 are respectively closed. There is an air inlet pipe 1 and an air outlet pipe 6. The double-layer bag type air hyperpermeable biofilm 1 is also provided with a high-density support plate 4 with a thickness of 5mm and porous, and the whole device is rolled into a spiral shape by the support plate 4. , and the positions of the air inlet pipe 1 and the air outlet pipe 6 are also provided with an air inlet 2 and an air outlet 5 correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com