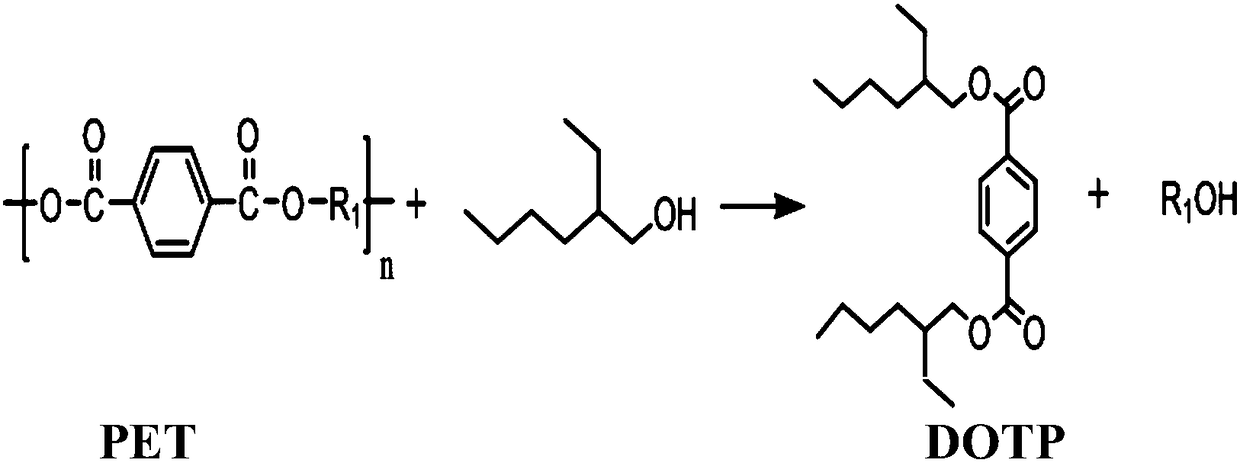

Method for preparing diisooctyl terephthalate through catalyzing alcoholysis of polyethylene terephthalate by choline eutectic ionic liquid

A technology of polyethylene terephthalate and poly-pair, which is applied in the preparation of ester group and hydroxyl group, etc., can solve the problems of slow reaction, unstable catalyst and long catalyst activation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Using PET granules as raw material, 5.0g PET raw material, 17.0g isooctyl alcohol and 0.25g choline deep eutectic ionic liquid catalyst were added successively in a 50ml three-necked round-bottomed flask. The raw materials for the synthesis catalyst were choline chloride and zinc acetate. The molar ratio is 1:2, and the synthesis conditions are 70°C, 120min. The reaction temperature was controlled at 175° C. under normal pressure, condensed and refluxed for 60 minutes, and then cooled to room temperature. Under these conditions, the degradation rate of PET is 100%, and the selectivity of di-isooctyl terephthalate (DOTP) is 78.2%.

Embodiment 2

[0026] Using PET granules as raw material, 5.0g PET raw material, 17.0g isooctyl alcohol and 0.25g choline deep eutectic ionic liquid catalyst were added successively in a 50ml three-necked round-bottomed flask. The raw materials for the synthesis catalyst were choline chloride and zinc acetate. The molar ratio is 1:1.5, and the synthesis conditions are 70°C, 120min. The reaction temperature was controlled at 185° C. under normal pressure, condensed and refluxed for 60 minutes, and then cooled to room temperature. Under these conditions, the degradation rate of PET is 100%, and the selectivity of di-isooctyl terephthalate (DOTP) is 82.5%.

Embodiment 3

[0028] Using PET granules as raw material, 5.0g PET raw material, 17.0g isooctyl alcohol and 0.25g choline deep eutectic ionic liquid catalyst were added successively in a 50ml three-necked round-bottomed flask. The raw materials for the synthesis catalyst were choline chloride and zinc acetate. The molar ratio is 1:0.25, and the synthesis conditions are 50°C, 240min. The reaction temperature was controlled at 185° C. under normal pressure, condensed and refluxed for 60 minutes, and then cooled to room temperature. Under these conditions, the degradation rate of PET is 99.2%, and the selectivity of di-isooctyl terephthalate (DOTP) is 79.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com