High-leveling polyester resin as well as preparation method and application thereof

A technology of polyester resin and flat polyester, which is used in the preparation of HAA system powder coatings and high-leveling polyester resins. It can solve the problems of insufficient leveling on the surface of the coating film and difficulty in obtaining a high-leveling coating film, and achieve long gelation time. , good fluidity, soft chain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

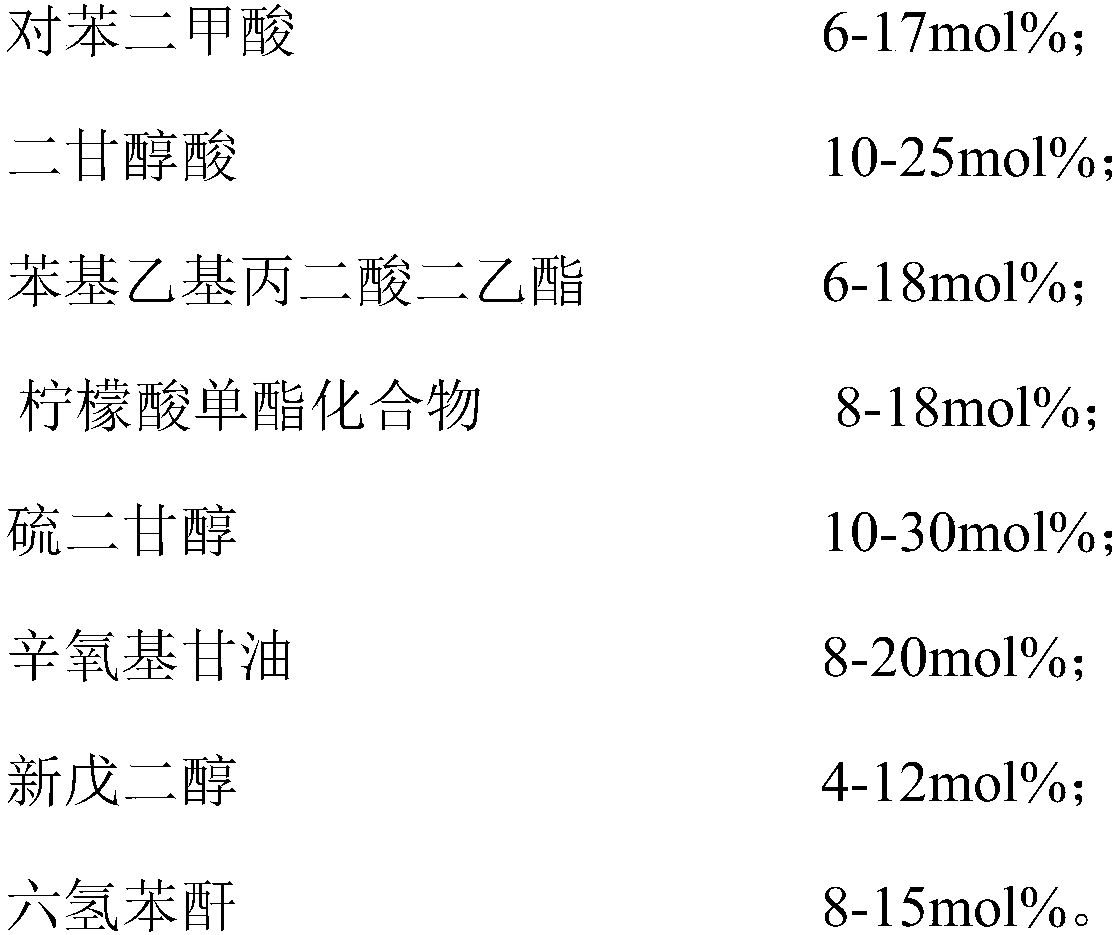

[0027] The high leveling polyester resin described in this embodiment, based on the total amount of the polyester resin, its preparation raw materials include the following raw material components in molar percentages:

[0028]

[0029]

[0030] Wherein, the citric acid monoester compound is a compound obtained by esterifying a hydroxyl group in a citric acid molecule with acrylic acid, and has the following structure: a compound obtained by esterifying a hydroxyl group in a citric acid molecule with acrylic acid, and has the following structure: The structure shown:

[0031]

[0032] Dissolve citric acid and acrylic acid in toluene solvent at a molar ratio of 1:3, add concentrated sulfuric acid accounting for 0.5-1.5wt% of the total molar weight of raw materials as a catalyst, and control the temperature at 108-115°C for 2-6 hours of esterification with water , and then the toluene solvent and excess acrylic acid were removed by vacuum distillation to obtain the citr...

Embodiment 2

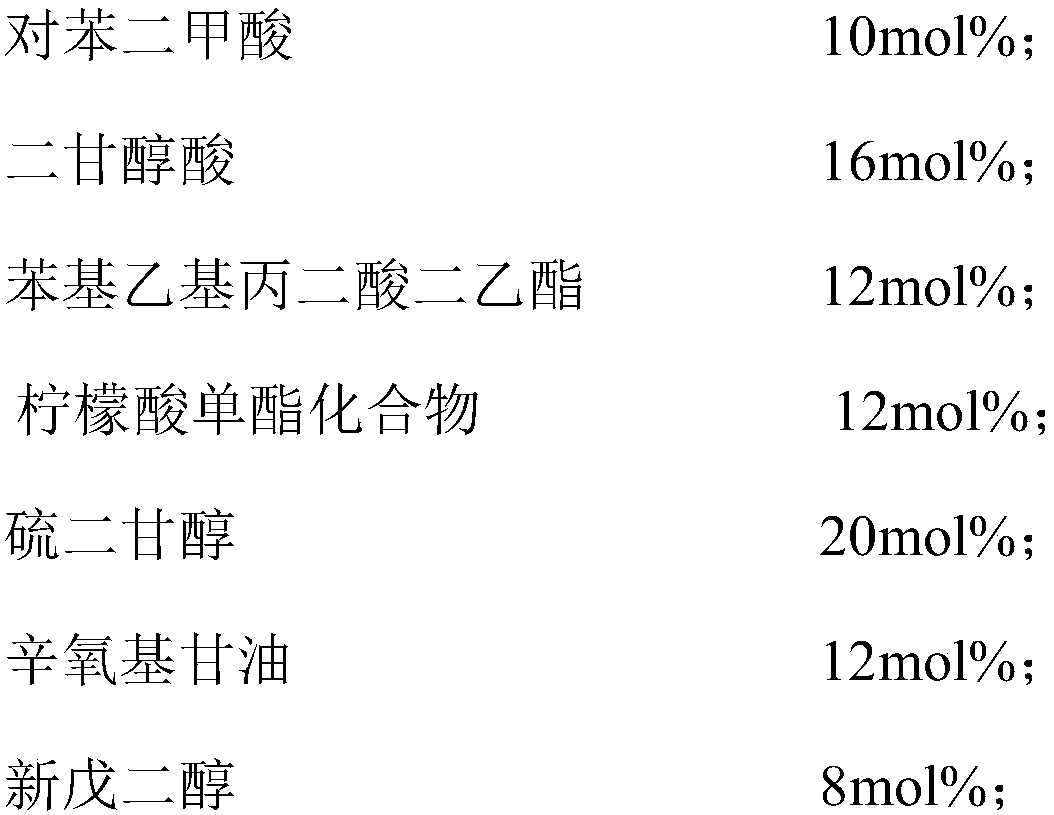

[0040] Described high-leveling polyester resin, based on the total amount of the polyester resin, its preparation raw materials include the following raw material components in molar percentages:

[0041]

[0042] The structure and preparation method of the citric acid monoester compound described in this example are the same as those in Example 1.

[0043] The preparation method of the high leveling polyester resin described in this embodiment is the same as that in Embodiment 1.

[0044] After testing, the polyester resin prepared in this example has an acid value of 30 mgKOH / g and a softening point of 102°C.

Embodiment 3

[0046] Described high-leveling polyester resin, based on the total amount of the polyester resin, its preparation raw materials include the following raw material components in molar percentages:

[0047]

[0048]

[0049] The structure and preparation method of the citric acid monoester compound described in this example are the same as those in Example 1.

[0050] The preparation method of the high leveling polyester resin described in this embodiment is the same as that in Embodiment 1.

[0051] After testing, the acid value of the polyester resin prepared in this example is 28mgKOH / g, and the softening point is 113°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com