Macromolecular anti-crack waterproof mortar and preparation method thereof

A waterproof mortar and polymer technology, applied in the field of polymer anti-crack waterproof mortar and its preparation, can solve the problems of body damage, long anti-seepage effect, and performance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A polymer anti-cracking waterproof mortar, made of the following raw materials in parts by weight: 100 parts of cement, 100 parts of sand, 30 parts of reinforcing filler, 1 part of superplasticizer, and 100 parts of water;

[0035] The crack-resistant waterproof mortar is made by the following steps:

[0036] Step S1: Add cement, sand, reinforcing filler, and 1 / 3 of the water into the stirring tank, and stir for 3 hours under the conditions of the rotation speed of 120r / min and the temperature of 35°C to obtain the first mixture;

[0037] Step S2: Add the first mixture, high-efficiency superplasticizer and remaining water prepared in step S1 into the stirring tank, and stir for 5 hours at a rotating speed of 60 r / min to prepare crack-resistant and waterproof mortar.

[0038] The high-efficiency water reducer is made by the following steps:

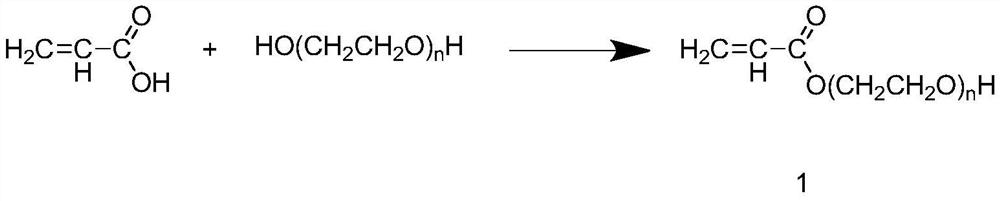

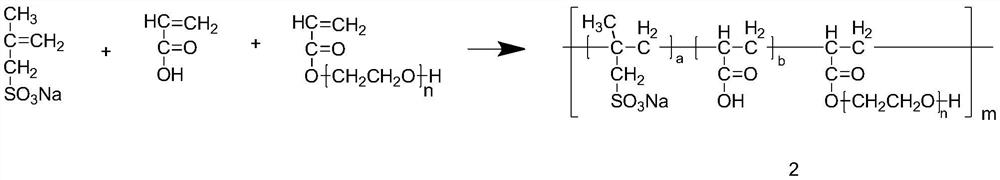

[0039] Step A1: Add polyethylene glycol and p-diphenol into the reactor, add acrylic acid and p-toluenesulfonic acid at a speed of ...

Embodiment 2

[0049] A polymer anti-cracking waterproof mortar, made of the following raw materials in parts by weight: 125 parts of cement, 110 parts of sand, 35 parts of reinforcing filler, 2 parts of superplasticizer, and 110 parts of water;

[0050] The crack-resistant waterproof mortar is made by the following steps:

[0051] Step S1: Add cement, sand, reinforcing filler, and 1 / 3 of the water into the stirring tank, and stir for 3 hours under the conditions of a rotating speed of 120 r / min and a temperature of 40° C. to obtain the first mixture;

[0052] Step S2: Add the first mixture, high-efficiency superplasticizer and remaining water prepared in step S1 into the stirring tank, and stir for 5 hours at a rotating speed of 80 r / min to prepare crack-resistant and waterproof mortar.

[0053] The high-efficiency water reducer is made by the following steps:

[0054] Step A1: Add polyethylene glycol and p-diphenol into the reactor, add acrylic acid and p-toluenesulfonic acid at a speed o...

Embodiment 3

[0064] A polymer anti-cracking waterproof mortar, made of the following raw materials in parts by weight: 180 parts of cement, 130 parts of sand, 40 parts of reinforcing filler, 3 parts of superplasticizer, and 120 parts of water;

[0065] The crack-resistant waterproof mortar is made by the following steps:

[0066] Step S1: Add cement, sand, reinforcing filler, and 1 / 3 of water into the stirring tank, and stir for 5 hours under the conditions of rotating speed of 150r / min and temperature of 35°C to obtain the first mixture;

[0067] Step S2: Add the first mixture, high-efficiency superplasticizer and remaining water prepared in step S1 into the stirring tank, and stir for 8 hours at a rotation speed of 60 r / min to prepare crack-resistant and waterproof mortar.

[0068] The high-efficiency water reducer is made by the following steps:

[0069] Step A1: Add polyethylene glycol and p-diphenol into the reactor, add acrylic acid and p-toluenesulfonic acid at a speed of 120r / min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com