Formula of wear-resistant white vulcanized shoe foxing and preparation method thereof

A technology for vulcanizing shoes and fences, applied in the field of rubber preparation, can solve the problems of wear and tear of fences, large amount of wear, affecting the life of a pair of shoes, etc., and achieve the effects of improving torsion resistance, improving wear performance and good viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

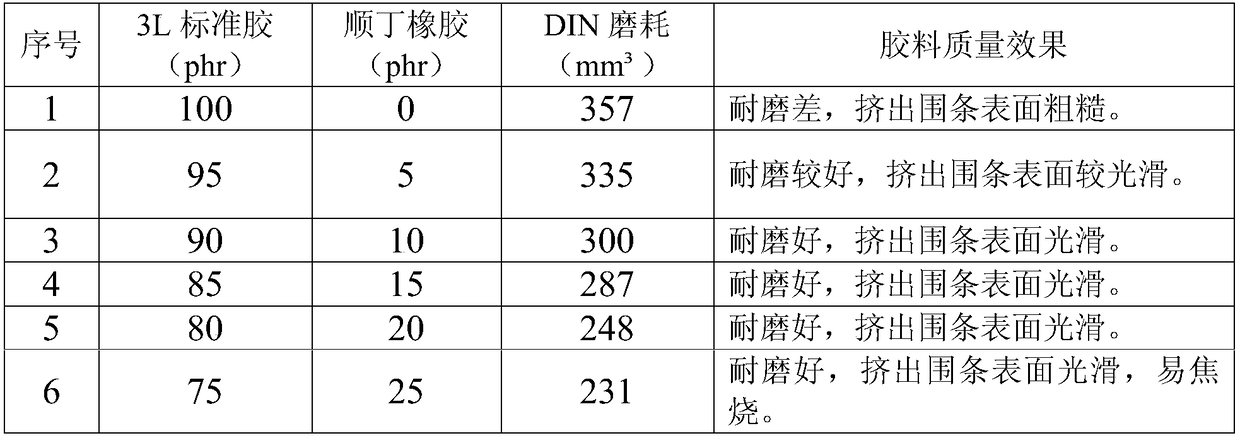

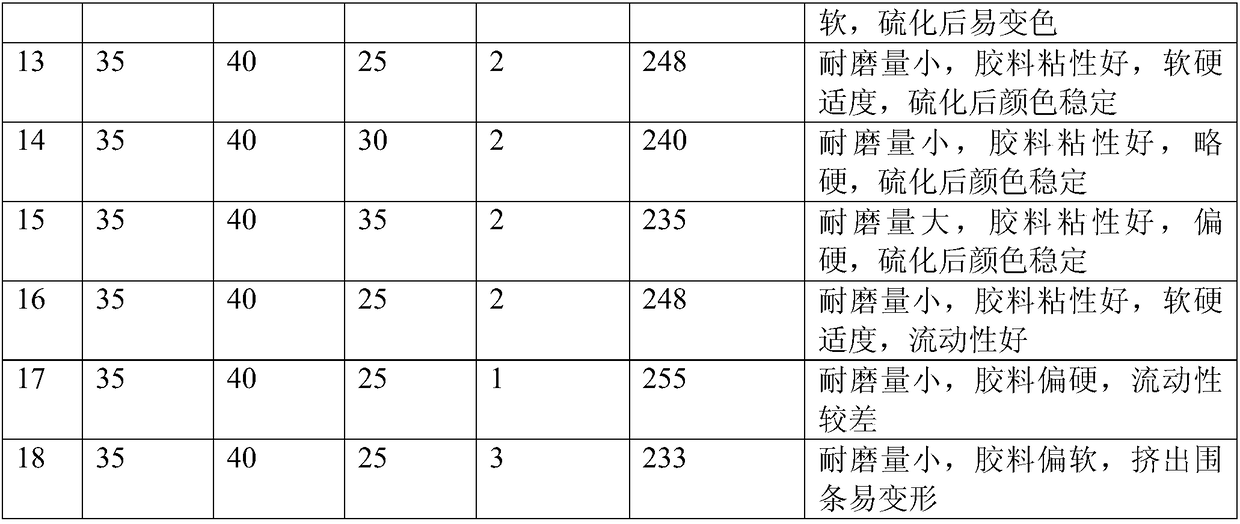

Method used

Image

Examples

Embodiment 1

[0030] A formula of wear-resistant white skirt for vulcanized shoes, which is composed of the following materials in parts by weight: 80 parts of second-stage masticated rubber, 20 parts of butadiene rubber, 5 parts of zinc oxide by indirect method, 1 part of stearic acid, and 2 parts of dispersant , 1 part of anti-aging agent BHT, 3.5 parts of polyethylene glycol, 35 parts of superfine white carbon black, 40 parts of nano-calcium carbonate, 25 parts of titanium dioxide, 1 part of Si69-50, 2 parts of C5 xylene resin, 1.8 parts of sulfur, 2.5 parts of vulcanization accelerator.

[0031] Wherein, the vulcanization accelerator is composed of 0.5 parts of composite accelerator AC-p84 and 2 parts of accelerator DM.

[0032] Preparation method: (1) put two-stage plasticized rubber, butadiene rubber, stearic acid, indirect zinc oxide, polyethylene glycol, anti-aging agent BHT, C5 xylene resin, and vulcanization accelerator into the preheated temperature In the internal mixer at 80-9...

Embodiment 2

[0034] A wear-resistant white skirting formula for vulcanized shoes, which is composed of the following materials in parts by weight: 90 parts of two-stage masticated rubber, 10 parts of butadiene rubber, 4.5 parts of zinc oxide by indirect method, 1.2 parts of stearic acid, and 1.8 parts of dispersant , 1.2 parts of anti-aging agent BHT, 4 parts of polyethylene glycol, 40 parts of superfine white carbon black, 35 parts of nano calcium carbonate, 28 parts of titanium dioxide, 1.5 parts of Si69-50, 1.8 parts of C5 xylene resin, 1.7 parts of sulfur, 2.5 parts of vulcanization accelerator.

[0035] Wherein, the vulcanization accelerator is composed of 0.5 parts of composite accelerator AC-p84 and 2 parts of accelerator DM.

[0036] The preparation method is the same as that of Example 1.

Embodiment 3

[0038] A wear-resistant white skirting formula for vulcanized shoes, which is composed of the following materials in parts by weight: 85 parts of second-stage masticated rubber, 15 parts of butadiene rubber, 4.8 parts of zinc oxide by indirect method, 1.4 parts of stearic acid, and 2.2 parts of dispersant , 1.3 parts of anti-aging agent BHT, 3.7 parts of polyethylene glycol, 37 parts of superfine white carbon black, 32 parts of nano-calcium carbonate, 30 parts of titanium dioxide, 1.3 parts of Si69-50, 1.5 parts of C5 xylene resin, 1.9 parts of sulfur, 2.5 parts of vulcanization accelerator.

[0039] Wherein, the vulcanization accelerator is composed of 0.5 parts of composite accelerator AC-p84 and 2 parts of accelerator DM.

[0040] The preparation method is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com