Coke dry quenching coke pot liner

A lining plate and coke coke technology, applied in the field of CDQ coke tank lining plate, can solve the problems of frequent maintenance, reduced impact resistance, low lining plate strength, etc., to reduce maintenance and operation costs, reduce heat loss, heat insulation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The CDQ coke tank liner of the present invention comprises a liner body and a liner keel.

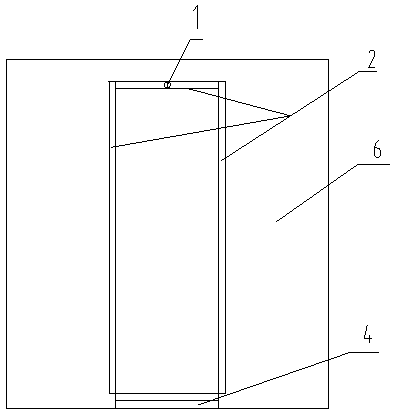

[0030] see now figure 1 , figure 1 It is a structural schematic diagram of the CDQ coke tank liner according to the embodiment of the present invention. As shown in the figure, the liner body is made of refractory castable, molded and baked. It is a rectangular block with a length of 539mm, a width of 500mm, and a thickness of 65mm. The length of the block is provided with grooves towards the bottom. Each block weighs 40-50kg, and its heavy-duty working temperature is 950-1050°C.

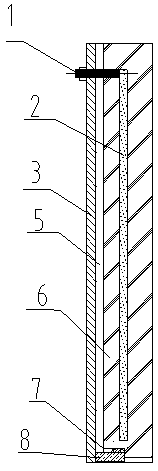

[0031] The liner keel is made of φ12mm stainless steel in a Π-shaped bracket, and the Π-shaped bracket is arranged as a liner keel in the length direction inside the block, and the middle part of the top of the Π-shaped stainless steel bracket is welded to the head of a bolt to make the screw rod and the bracket The plane is vertical and the screw protrudes a certain distance from the surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com