Biogas engineering homogeneous stirring tank

A homogeneous mixing and engineering technology, applied in the direction of biomass post-treatment, biomass pre-treatment, gas production bioreactor, etc., can solve the problems of difficult accurate metering and continuous or semi-continuous feeding, so as to avoid winding or The effect of blocking the pipeline, low failure rate, simple and reasonable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

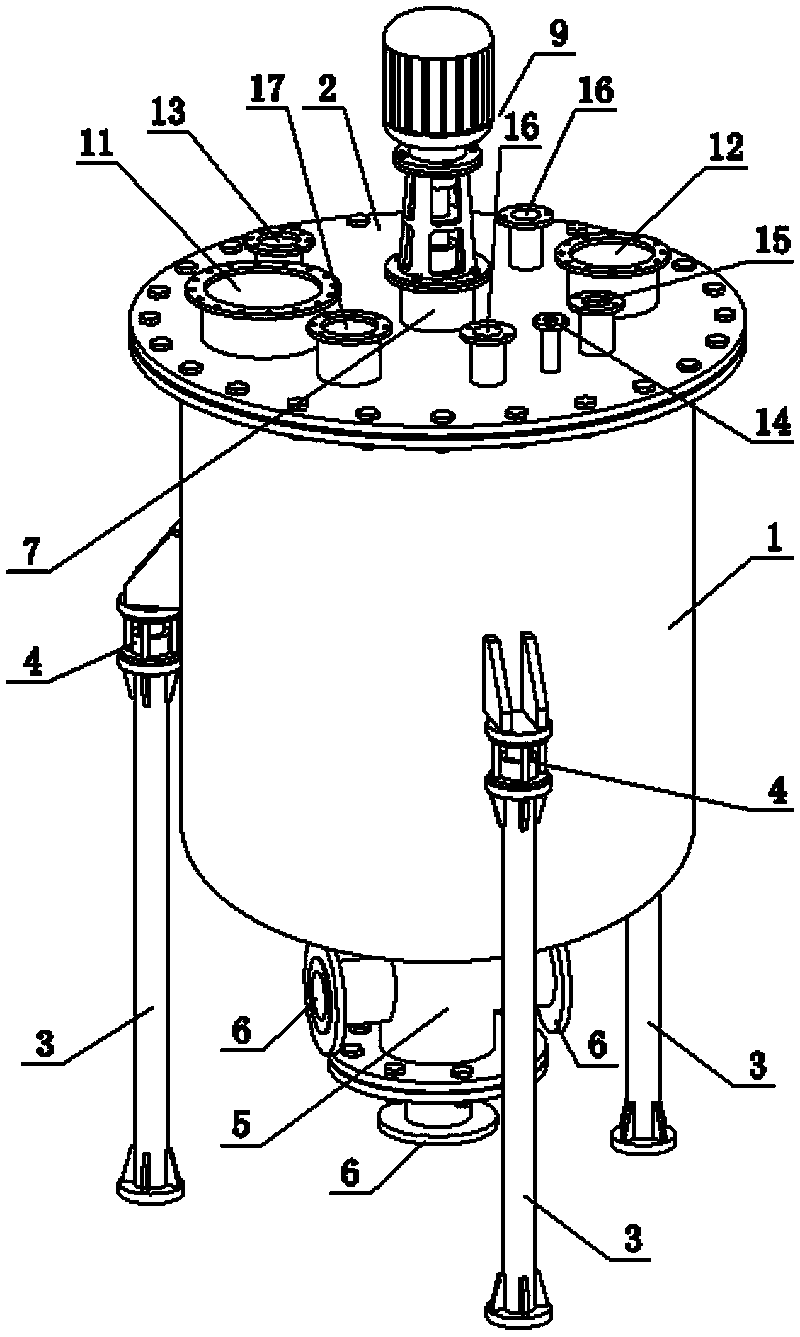

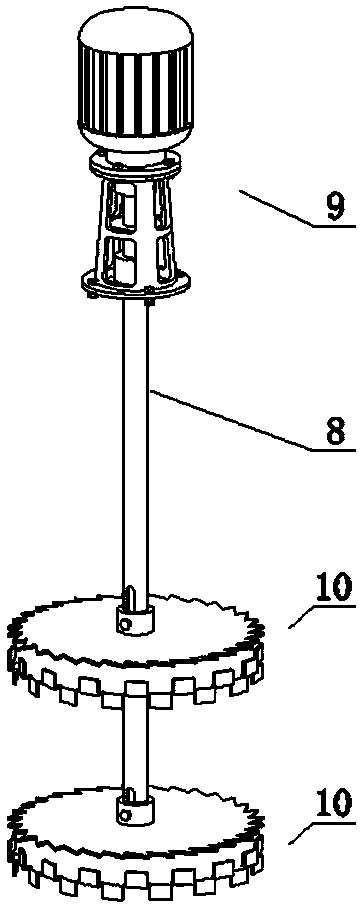

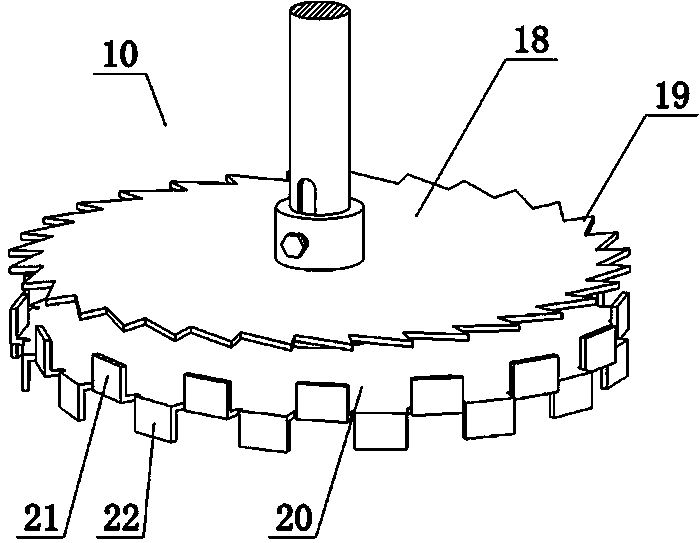

[0021] Such as figure 1 , figure 2 and image 3 As shown, a biogas engineering homogeneous mixing tank includes a controller, a tank body 1, a tank cover 2 and three legs 3, and each leg 3 is provided with a load cell 4; the lower part of the tank body 1 A discharge drum 5 is provided, and there are three discharge ports 6, wherein two discharge ports 6 are arranged on the side of the discharge drum 5, and one of the discharge ports 6 is arranged below the discharge drum 5; The middle part of the tank cover is provided with a mixer installation port 7, a mixer shaft 8 is installed on the mixer installation port 7 to vertically extend into the mixer 9 inside the tank body 1, and two disc-type cutters are installed on the mixer shaft 8 inside the tank body 1. Broken saw blade 10; tank cover 2 is provided with manhole 11, solid feed port 12, liquid feed port 13, tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com