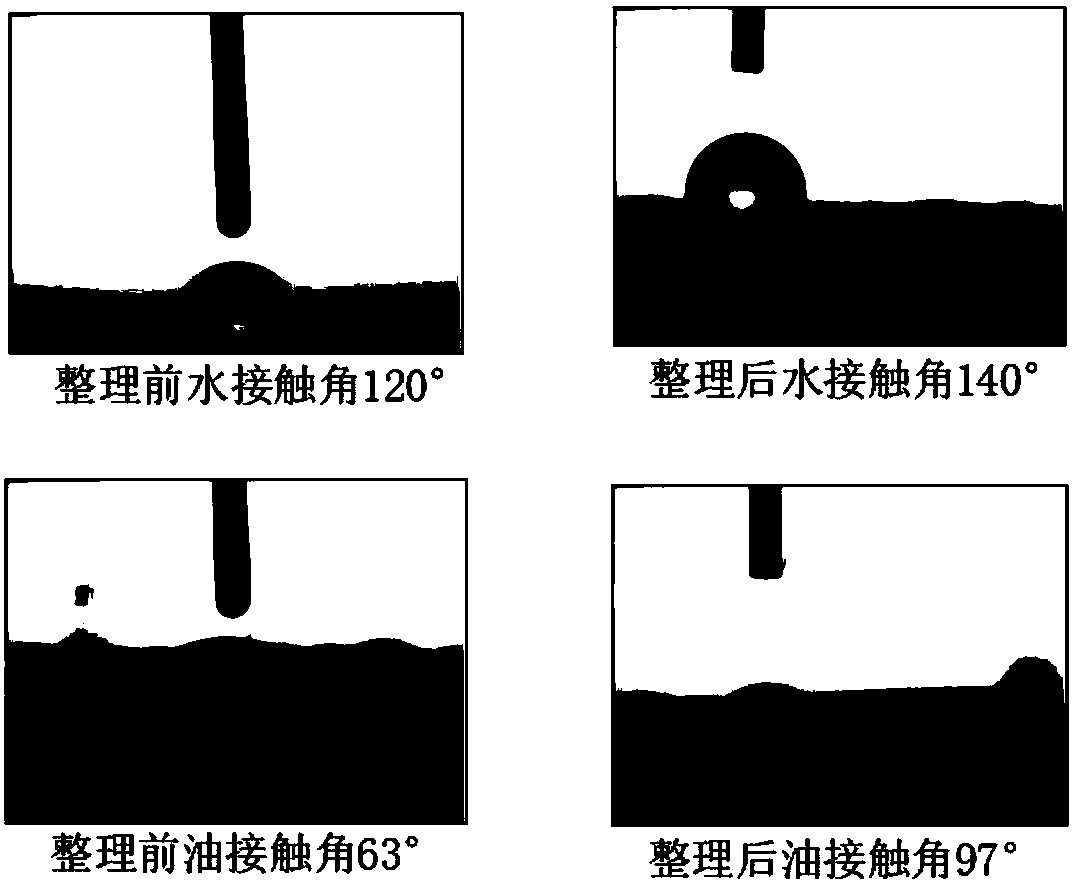

Preparation method of water-repellent oil-repellent anti-staining silk fabric

A water-repellent, oil-repellent, and anti-staining technology, which is applied in the field of preparation of anti-staining silk fabrics, can solve the problems of restricting the use of silk fabrics and fabric damage, so as to reduce fabric damage, prolong service life, and reduce cleaning times Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) Clean the cut silk fabric with absolute ethanol and dry it.

[0015] (2) Preparation of fluorine-containing finishing solution: Take 10 milliliters (solid content 25%) of fluorine-containing finishing agent in a beaker, add 80 milliliters of deionized water, stir well, add appropriate amount of acetic acid to the fluorine-containing finishing agent solution to adjust When the pH value is equal to 4.5, the preparation of the fluorine-containing finishing agent solution is completed.

[0016] (3) Soak the silk fabric dried in the step 1 in the fluorine-containing finishing agent solution for 5 minutes.

[0017] (4) Keep the liquid-carrying rate of the silk fabric at 80%, and roll it through the pad dyeing machine, and the excess rate of the silk fabric is 70%.

[0018] (5) Spread the silk fabric in an oven at a temperature of 58°C and pre-bake for 1 minute; take out the silk fabric, lay it in an oven at 128°C, and bake for 1 minute to complete the silk fabric's water...

Embodiment 2

[0020] (1) Clean the cut silk fabric with absolute ethanol and dry it.

[0021] (2) Preparation of fluorine-containing finishing solution: Take 10 milliliters (solid content 35%) of fluorine-containing finishing agent in a beaker, add 90 milliliters of deionized water, stir evenly, add appropriate amount of acetic acid to the fluorine-containing finishing agent solution to adjust When the pH value is equal to 5.5, the preparation of the fluorine-containing finishing agent solution is completed.

[0022] (3) Soak the silk fabric dried in step 1 in the fluorine-containing finishing agent solution for 6 minutes.

[0023] (4) Keep the liquid-carrying rate of the silk fabric at 90%, and roll it through a pad dyeing machine, and the excess rate of the silk fabric is 80%.

[0024] (5) Spread the silk fabric in an oven at 62°C and pre-bake for 3 minutes; take out the silk fabric, spread it in an oven at 132°C, and bake for 2 minutes to complete the silk fabric's water and oil repelle...

Embodiment 3

[0026] (1) Clean the cut silk fabric with absolute ethanol and dry it.

[0027] (2) Preparation of fluorine-containing finishing solution: Take 10 milliliters (solid content 30%) of fluorine-containing finishing agent in a beaker, add 90 milliliters of deionized water, stir evenly, add appropriate amount of acetic acid to the fluorine-containing finishing agent solution to adjust When the pH value is equal to 5, the preparation of the fluorine-containing finishing agent solution is completed.

[0028] (3) Soak the dried silk fabric in step 1 in the fluorine-containing finishing agent solution for 5 minutes.

[0029] (4) Keep the liquid-carrying rate of the real silk fabric at 80-90%, and roll it through a pad dyeing machine, and the excess rate of the silk fabric is 70%.

[0030] (5) Lay the real silk fabric in an oven at 60°C and pre-bake for 2 minutes; take out the silk fabric, lay it in an oven at 130°C, and bake for 1 minute to complete the silk fabric's water and oil rep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com