A kind of manufacturing method of cone enveloping cone worm pair

A manufacturing method and technology of a tapered worm, which is applied in the directions of worms, worm gears, components with teeth, etc., can solve the problems of unsatisfactory meshing ability of two sides of a tooth and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

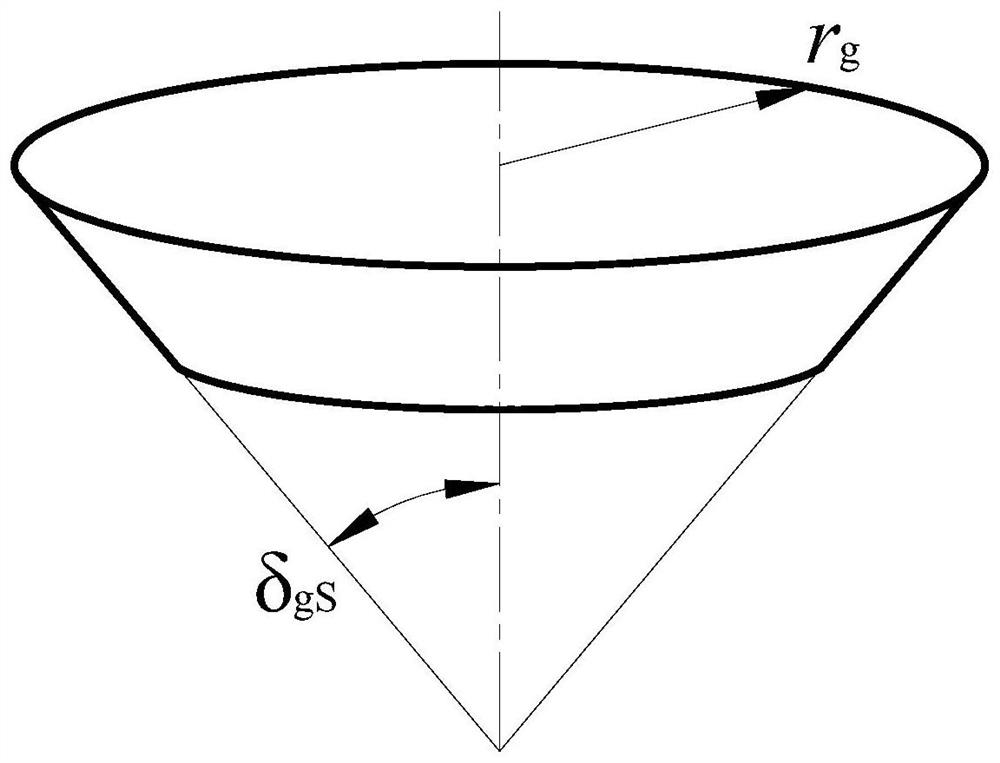

[0115] In this embodiment, the enveloping cone worm 1 rotates right, and the number of heads is Z 1 =1, the secondary axis of the cone enveloping cone worm is non-orthogonal, and the axis angle Σ=75°, the manufacturing method of this embodiment adopts the following steps:

[0116] Step 1. Set the coordinate parameters of the enveloping cone worm to be manufactured:

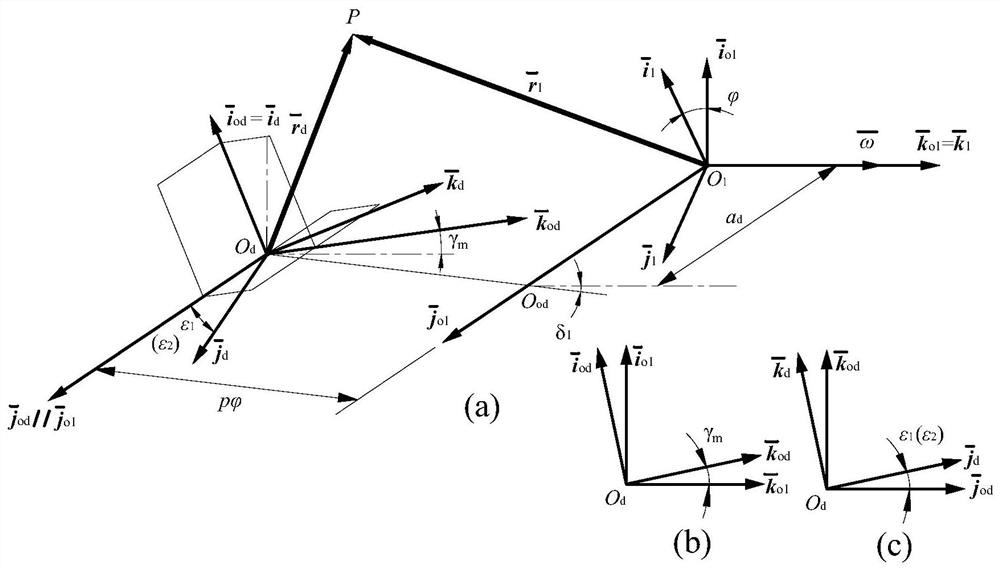

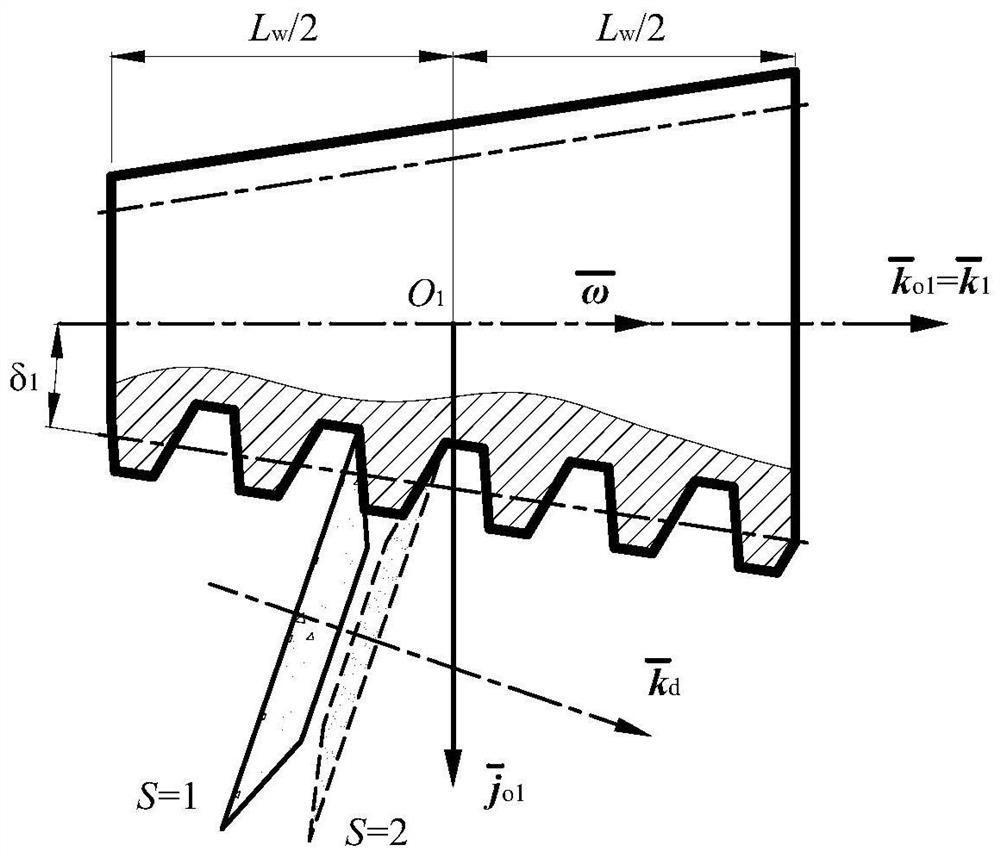

[0117] Conical Worm Blank and Moving Coordinate System The phases are fixed, the moving coordinate system σ 1 The unit basis vector of From the small end to the large end along the axis of the conical worm blank, the moving coordinate system σ 1 The coordinate origin O 1 Located on the axis of the bevel worm blank, is the thread length L of the enveloping bevel worm w the midpoint of

[0118]The static coordinate system of the cone worm blank is Static coordinate system σ o1 The unit basis vector of and the moving coordinate system σ 1 The unit basis vector of Coincident, along the axis of the beve...

Embodiment 2

[0168] The manufacturing method of the cone-enveloping cone-worm pair of this embodiment is the same as that of Embodiment 1, but the basic parameters and processing parameters of the cone-enveloping cone-worm pair are different.

[0169] The enveloping cone worm in this embodiment is right-handed, and the number of heads is Z 1 = 3, the two axes of the cone enveloping cone and worm pair are orthogonal, that is, the axis angle Σ = 90°, the center distance a = 100mm, the transmission ratio i 12 =18, according to the formula provided by the present invention, it can be estimated that the modulus of the enveloping cone worm along the sub-cone generatrix is:

[0170]

[0171] rounded to a standard value, take m δ =4mm; Enveloping cone worm length L w =0.73a=0.73×100=73mm, the lead angle γ of the enveloping cone worm at the reference point M m =15.818°, enveloping cone worm sub-cone angle δ 1 =5°, the radius r of the dedendum circle at the midpoint of the enveloping cone wor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com