Tube root waterproof structure and construction process thereof

A technology of structure and pipe root, applied in the field of pipe root waterproof structure and its construction technology, can solve the problems of short service life, poor adhesion, falling off, etc., and achieve high uniform thickness, good consistency, and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

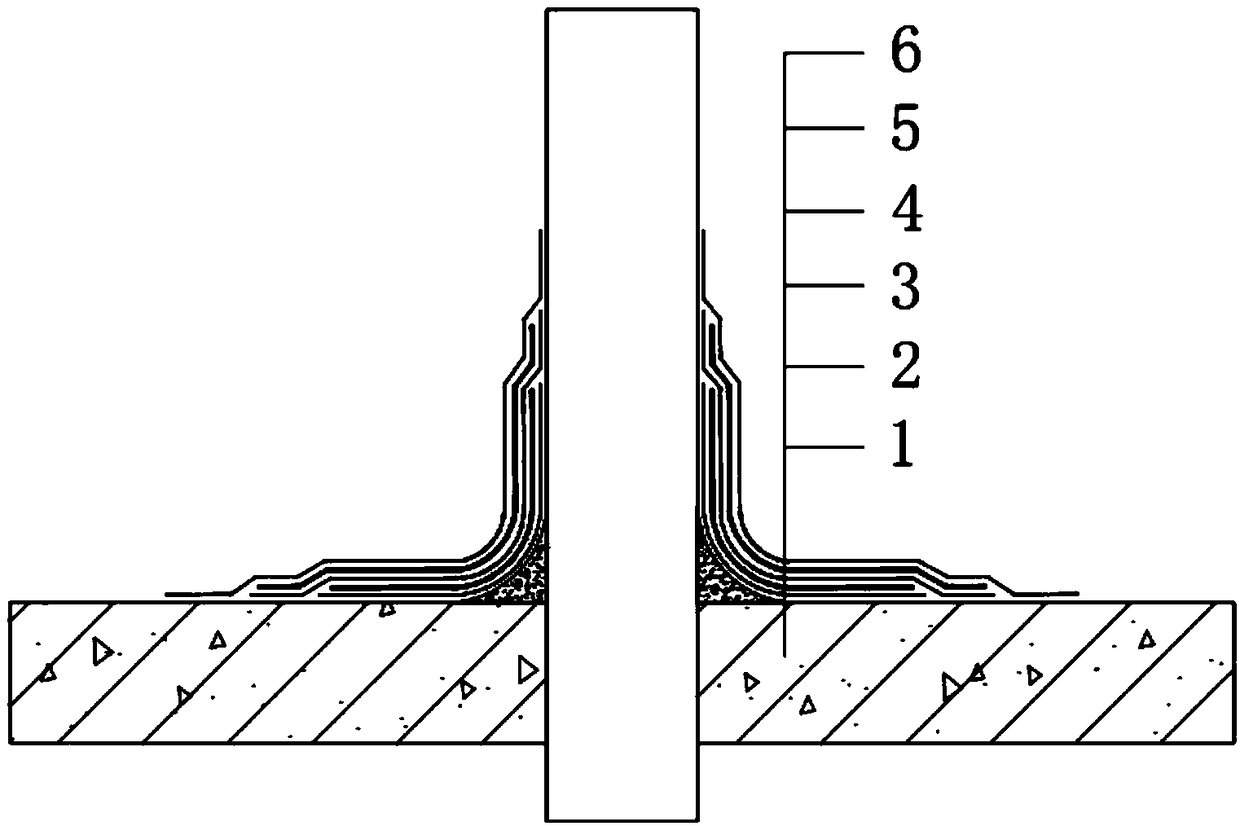

[0040] A pipe root waterproof structure has a 2-layer structure, a layer of carcass, and a layer of rubbery waterproof coating, wherein the carcass is non-woven fabric, and is constructed by the following method:

[0041] (1) Tube root treatment: clean the base surface near the tube root;

[0042] (2) Apply the first waterproof coating: apply rubber-like waterproof coating to the base surface near the pipe root, turn up 5cm to the pipe body, and extend 5cm to the plane;

[0043] (3) Lay the first layer of carcass: Lay non-woven fabric on the first layer of waterproof coating, turn it up 5cm to the pipe body, and extend it 5cm wide to the plane.

Embodiment 2

[0045] A pipe root waterproof structure has a 3-layer structure, with 1 layer of carcass and 2 layers of rubbery waterproof coating, wherein the carcass is non-woven fabric, and is constructed by the following method:

[0046] (1) Tube root treatment: clean the base surface near the tube root;

[0047] (2) Apply the first waterproof coating: apply rubber-like waterproof coating to the base surface near the pipe root, turn up 2cm to the pipe body, and extend 2cm to the plane;

[0048] (3) Laying the first layer of carcass: Lay non-woven fabric on the first waterproof coating, turn it up 2cm to the pipe body, and extend 2cm wide to the plane;

[0049] (4) Apply the second waterproof coating: Apply the rubber-like waterproof coating on the first layer of non-woven fabric, turn it up 2cm to the tube body, and extend 2cm wide to the plane, so that the rubber-like waterproof coating can completely soak and cover the non-woven fabric. spinning;

[0050] The application of the rubber-...

Embodiment 3

[0053] A pipe root waterproof structure has a 3-layer structure, with 1 layer of carcass and 2 layers of rubbery waterproof coating, wherein the carcass is non-woven fabric, and is constructed by the following method:

[0054] (1) Tube root treatment: clean the base surface near the tube root;

[0055] (2) Apply the first waterproof coating: apply rubber-like waterproof coating to the base surface near the pipe root, turn up 5cm to the pipe body, and extend 5cm to the plane;

[0056] (3) Lay the first layer of carcass: lay non-woven fabric on the first waterproof coating, turn it up 5cm to the pipe body, and extend it 5cm wide to the plane;

[0057] (4) Apply the second waterproof paint: paint the rubber waterproof paint on the first layer of non-woven fabric, turn it up 5cm to the pipe body, and extend it 5cm wide to the plane, so that the rubber waterproof paint is completely soaked and covered. spinning;

[0058] The application of the rubber-state waterproof paint and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com