Contact type three-dimensional tracking scanning probe

A technology of three-dimensional tracking and scanning probe, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of continuous and fast tracking of curvature, difficult processing, damage of measuring equipment, etc., and achieve simple and practical mechanical decoupling and good dynamic response performance , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The contact-type three-dimensional tracking scanning probe, its usage method and measuring principle of the present invention will be further described through the embodiments and with reference to the accompanying drawings.

[0041] The contact-type three-dimensional tracking scanning probe described in this embodiment is a component of the three-coordinate measuring machine, and is installed on the three-coordinate measuring machine when in use.

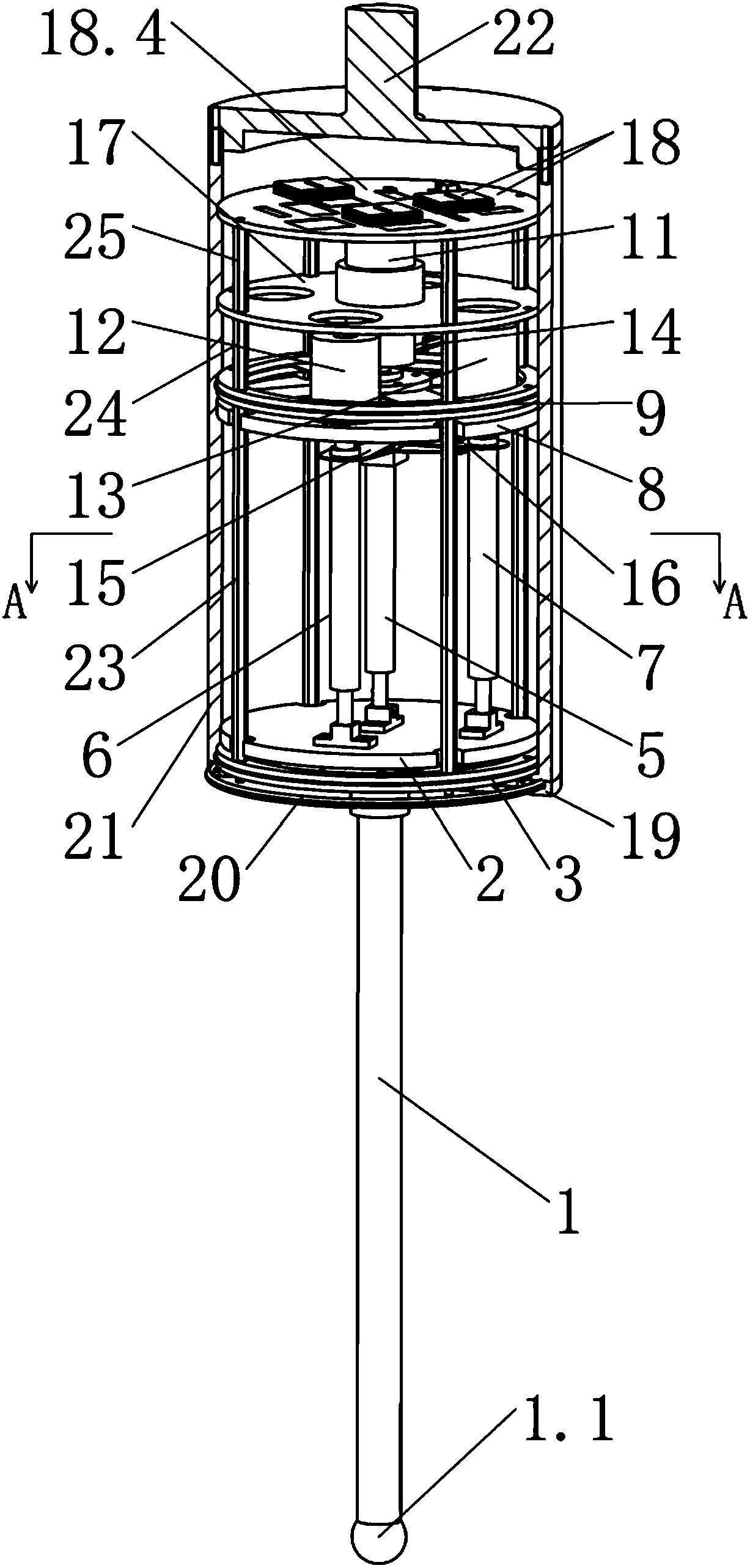

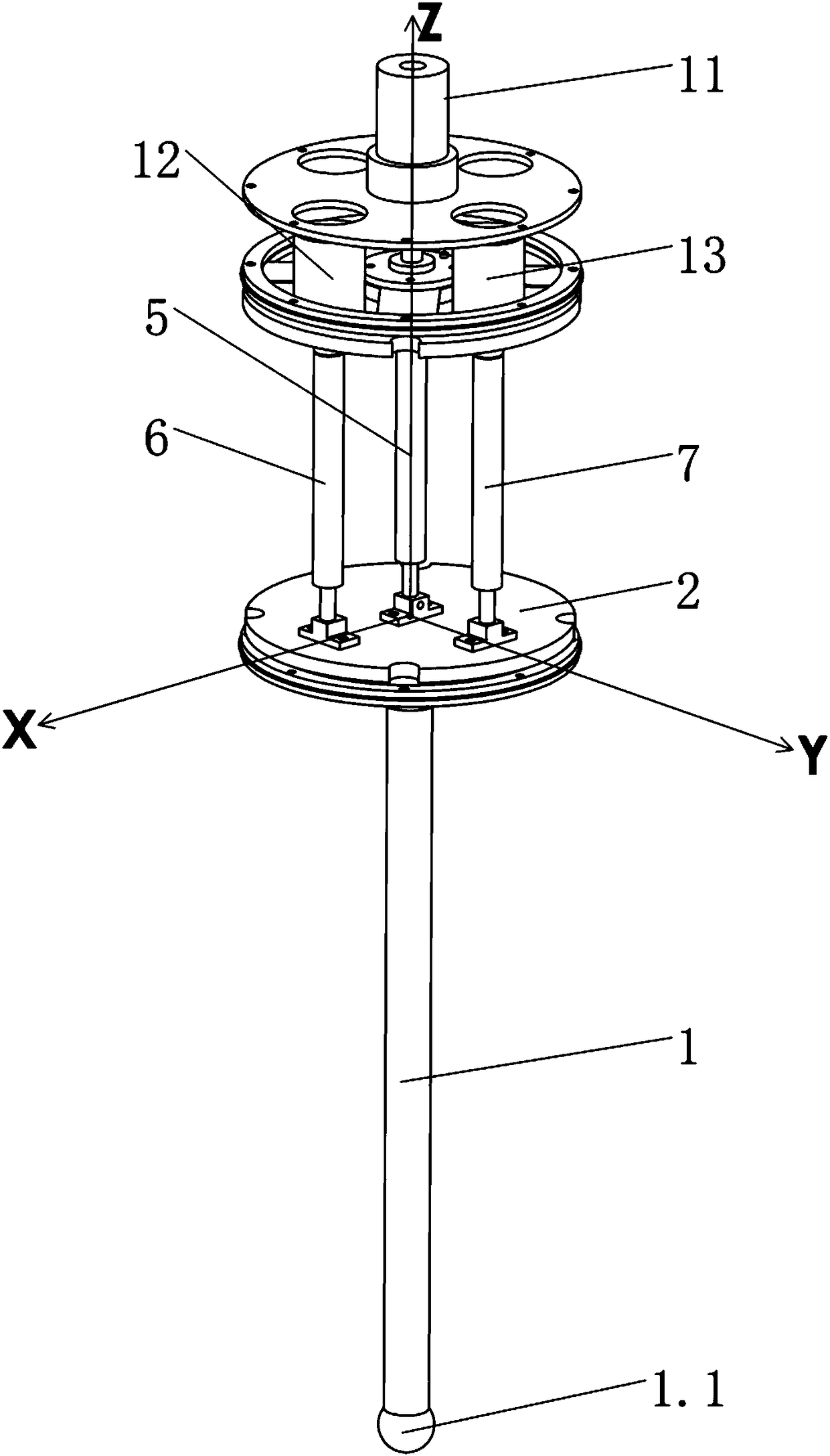

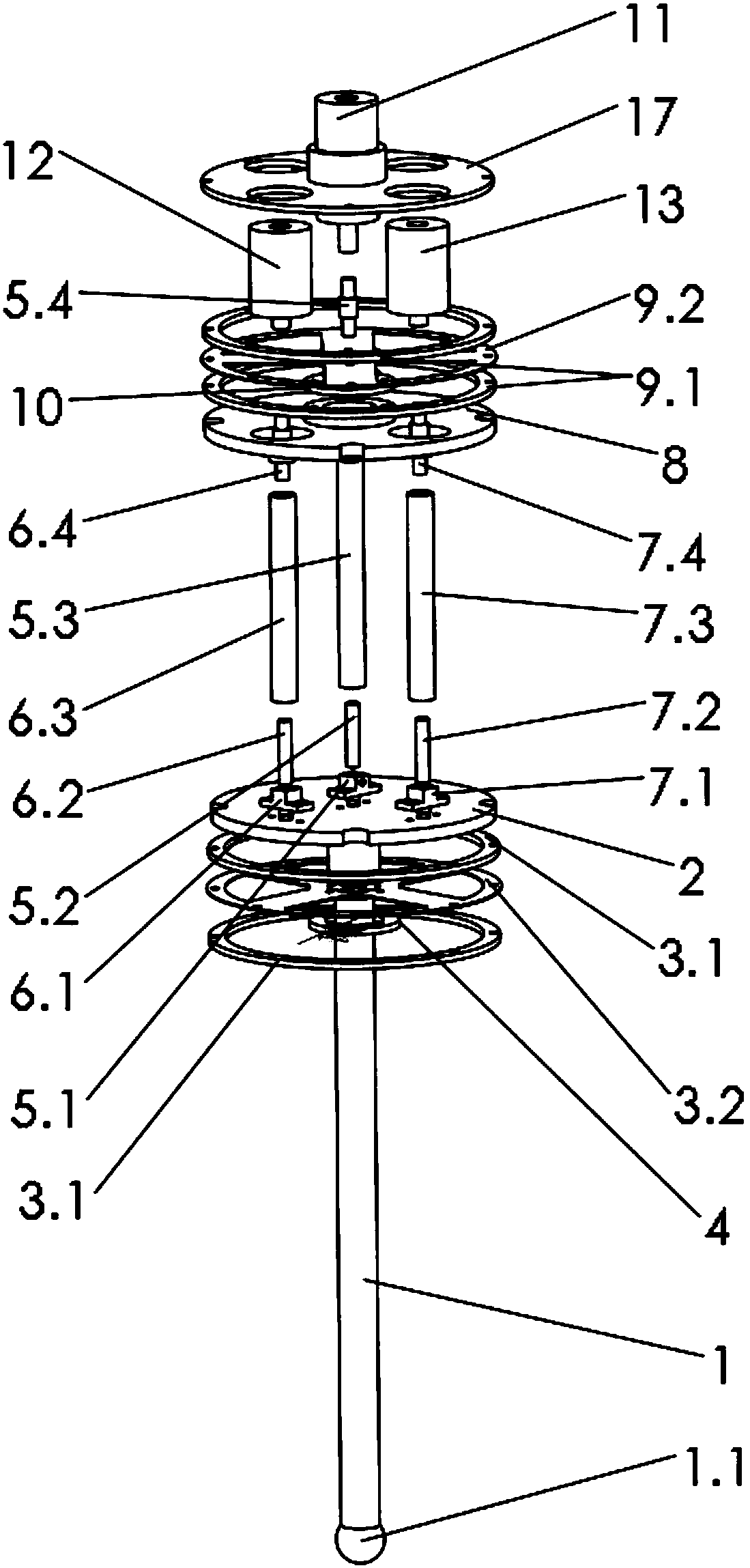

[0042] The structure of the contact type described in this embodiment is as follows: figure 1 As shown, it consists of a motion unit, a sensing unit, a limit unit, a signal processing unit 18 and an installation system for installing the motion unit, a sensing unit, a limit unit, and a signal processing unit.

[0043] The motor unit such as figure 1 , image 3 As shown, it includes probe 1, lower moving plate 2, lower return mechanism 3, lower fixing plate 4, Z-direction transmission mechanism 5, X-direction transmission m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com