Rod and wire surface defect online detection device and method

A detection device, rod and wire technology, applied in the field of optical measurement, can solve the problems of limited defect types, large amount of data, fusion of grayscale information and depth information, etc., to reduce shadows and uneven illumination, improve quality, and achieve image quality. Fusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

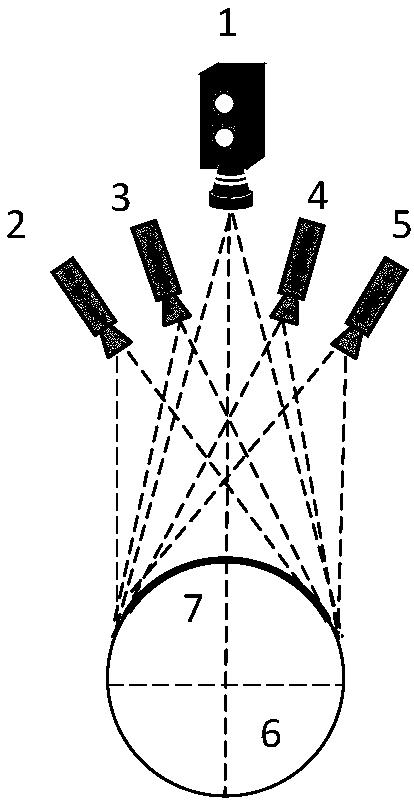

[0036] figure 1Among them, the multispectral camera 1 has four sensors of red, green, blue and near-infrared, which are sensitive to red, green, blue and near-infrared light respectively. The red light source 2, the green light source 3, the blue light source 4 and the near-infrared light source 5 are all LED monochromatic light sources, and the emission wavelengths are equal to the peak values of the spectral response curves of the four sensors corresponding to the multispectral camera. The optical path of the multispectral camera 1 passes through the axis of the rod wire 6, and the red light source 2, the green light source 3, the blue light source 4 and the near-infrared light source 5 are evenly distributed around the multispectral camera 1, and the light of different wavelengths emitted by the light source irradiates the rod. In the same region 7 on the surface of the wire 6 , the circumference of the region 7 is greater than 1 / 4 of the circumference of the rod and wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com