Structure of wear-resistant metal saw blade and processing method

A processing method and technology of wear-resistant steel, applied in metal processing equipment, grinding devices, manufacturing tools, etc., can solve the problems of low hardness of resin grinding wheel, reduced processing efficiency, chemical pollutants caused by spark dust, etc., to achieve cutting efficiency and Increased effectiveness, ease of heat dissipation and chip evacuation, effectiveness of avoiding chemical contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

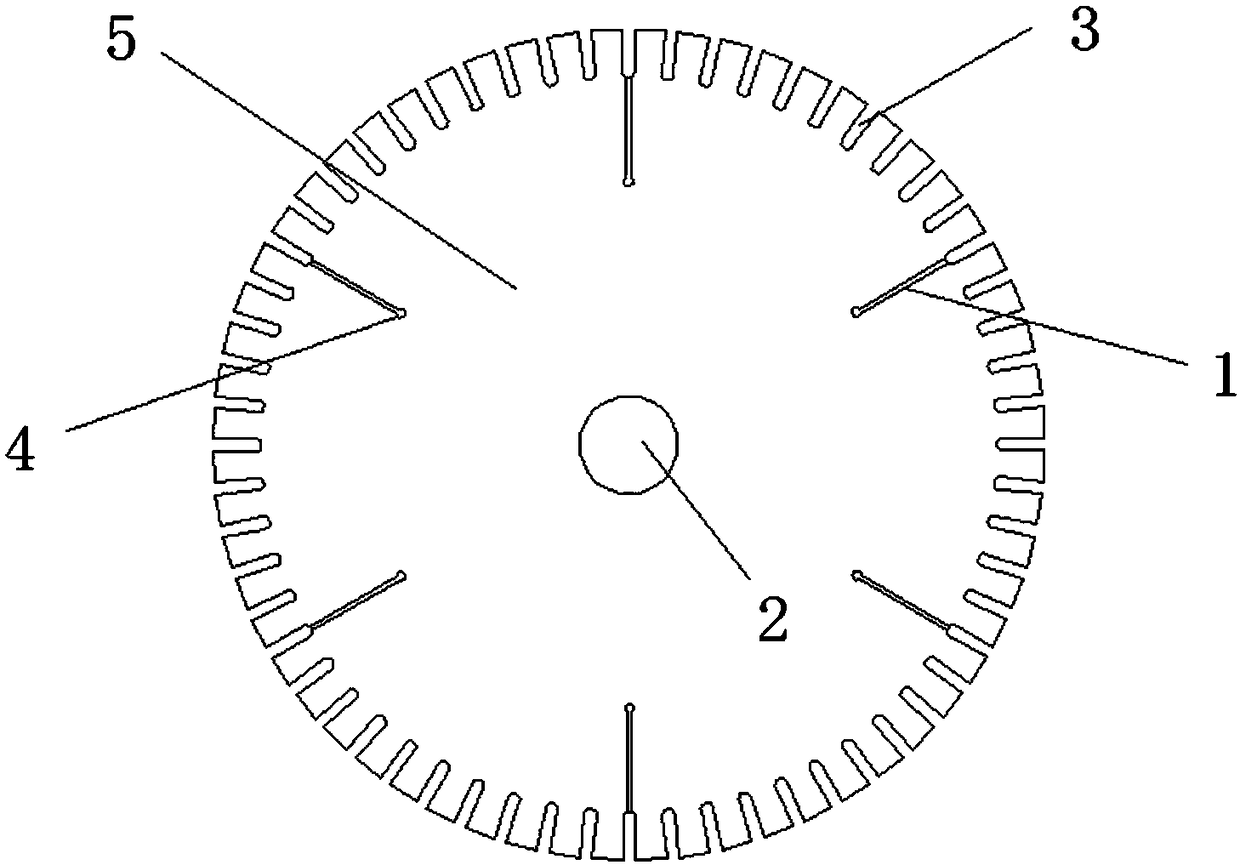

[0022] refer to figure 1 , a structure of a wear-resistant steel saw blade, comprising a saw blade body 5, a plurality of grooves 3 are provided along the side of the saw blade body 5, and sixty grooves 3 are arranged at equal angles to facilitate hacksaw The blade dissipates heat and removes chips during the cutting process. The surface of the saw blade body 5 is provided with a plurality of second through holes 4, and the second through holes 4 are arranged in four and arranged at an equal angle. The saw blade is thermally expanded and deformed during the cutting process. The surface of the saw blade body 5 is provided with a long hole 1 communicating with the second through hole 4 and the groove 3 respectively, and the center of the surface of the saw blade body 5 is provided with a first through hole. 2. By adding the first through hole 2, the installation of the saw blade is facilitated.

[0023] The present invention also provides a method for processing the structure o...

Embodiment 2

[0031] refer to figure 1 , a structure of a wear-resistant steel saw blade, comprising a saw blade body 5, a plurality of grooves 3 are provided along the side of the saw blade body 5, and sixty grooves 3 are arranged at equal angles to facilitate hacksaw The blade dissipates heat and removes chips during the cutting process. The surface of the saw blade body 5 is provided with a plurality of second through holes 4, and the second through holes 4 are arranged in four and arranged at an equal angle. The saw blade is thermally expanded and deformed during the cutting process. The surface of the saw blade body 5 is provided with a long hole 1 communicating with the second through hole 4 and the groove 3 respectively, and the center of the surface of the saw blade body 5 is provided with a first through hole. 2. By adding the first through hole 2, the installation of the saw blade is facilitated.

[0032] The present invention also provides a method for processing the structure o...

Embodiment 3

[0040] refer to figure 1 , a structure of a wear-resistant steel saw blade, comprising a saw blade body 5, a plurality of grooves 3 are provided along the side of the saw blade body 5, and sixty grooves 3 are arranged at equal angles to facilitate hacksaw The blade dissipates heat and removes chips during the cutting process. The surface of the saw blade body 5 is provided with a plurality of second through holes 4, and the second through holes 4 are arranged in four and arranged at an equal angle. The saw blade is thermally expanded and deformed during the cutting process. The surface of the saw blade body 5 is provided with a long hole 1 communicating with the second through hole 4 and the groove 3 respectively, and the center of the surface of the saw blade body 5 is provided with a first through hole. 2. By adding the first through hole 2, the installation of the saw blade is facilitated.

[0041] The present invention also provides a method for processing the structure o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap