An agricultural seed processing line

A technology for agricultural seeds and processing lines, which is applied in the directions of seed coating/seed dressing, types of packaging items, transportation and packaging, etc., which can solve problems such as hidden dangers to personal safety of staff, increase of equipment manufacturing costs, and large equipment space. , to achieve the effect of strong continuity, preventing seed agglomeration and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

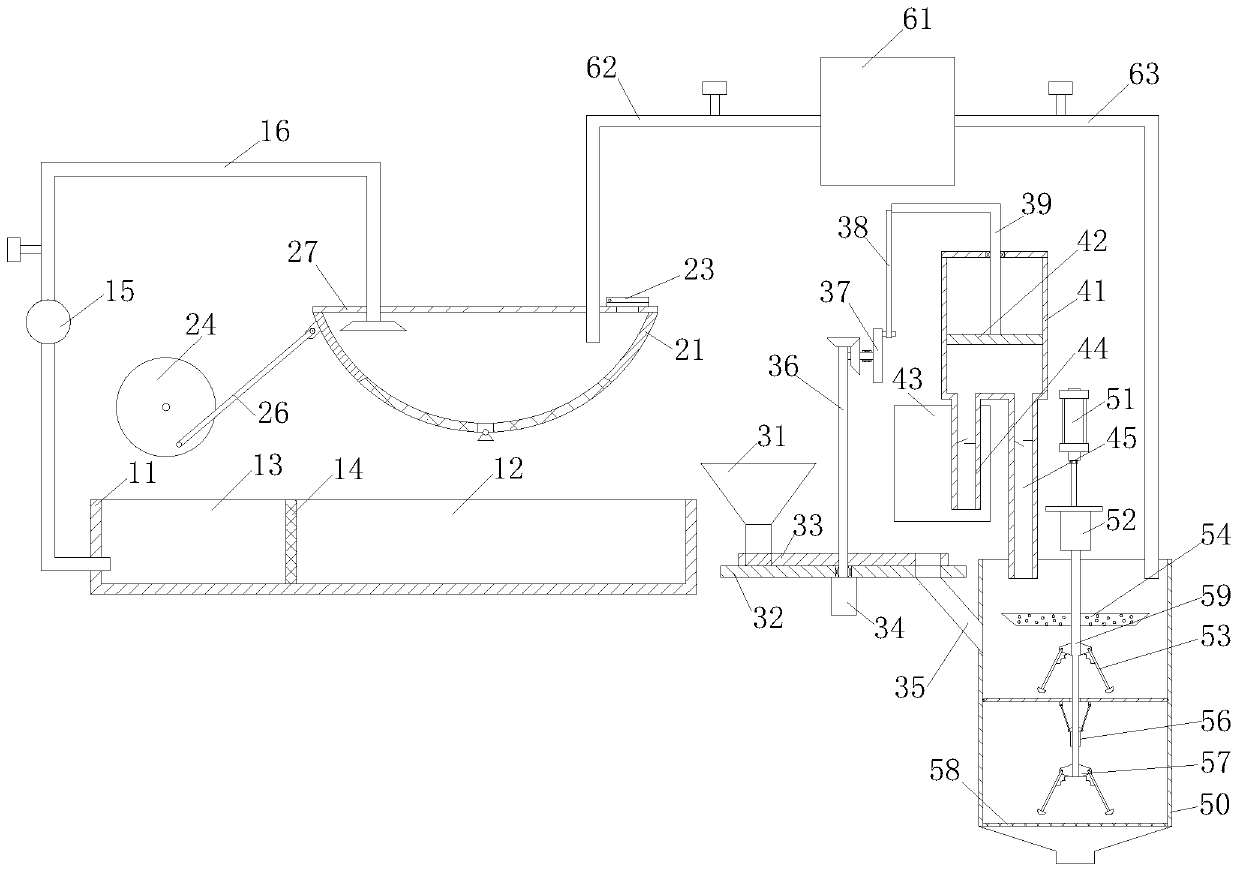

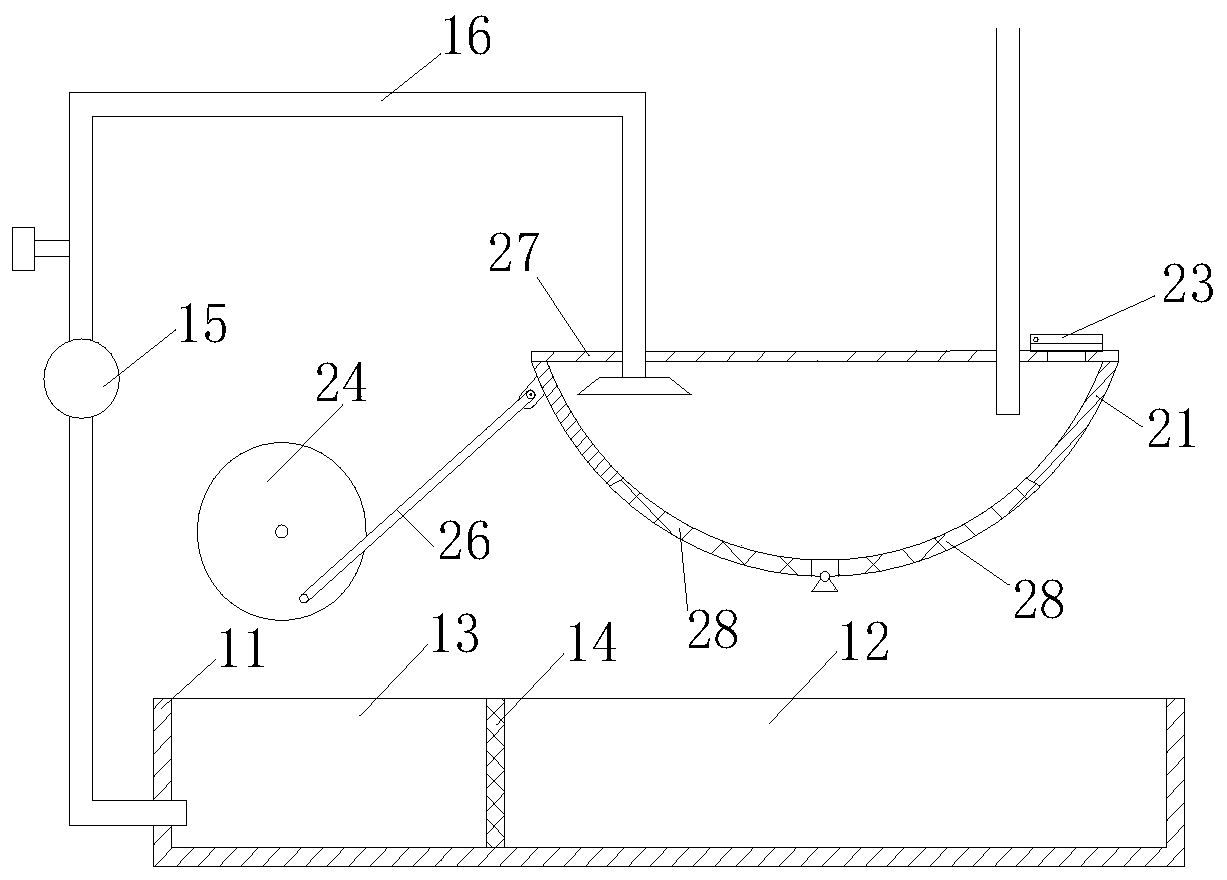

[0059] refer to figure 1 and Figure 10 , an agricultural seed processing line disclosed in this embodiment includes a coating device and a packaging device arranged in sequence according to the process flow of the processing line.

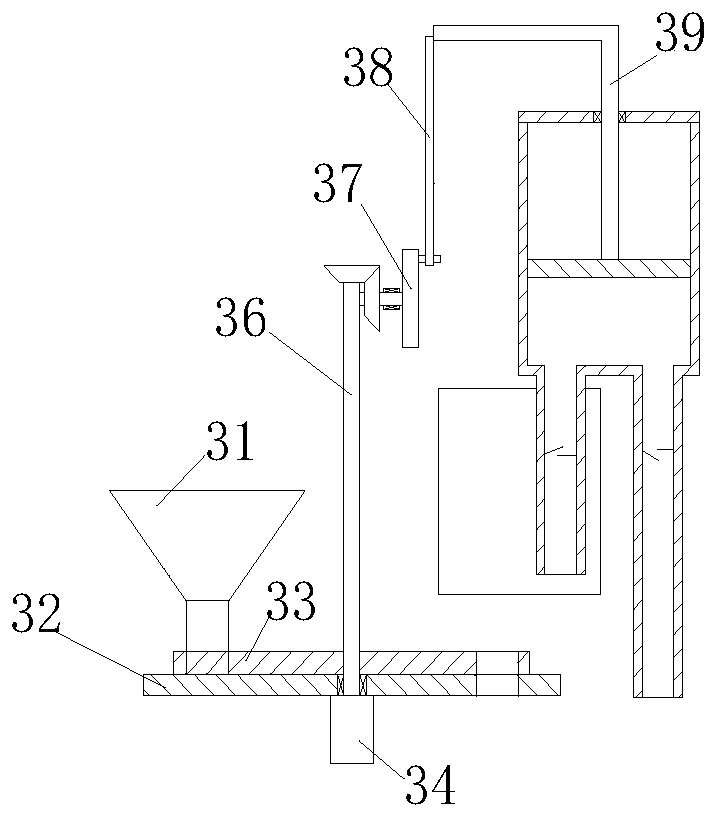

[0060] refer to figure 1 , the coating device includes a pretreatment system, a feeding system and a coating system arranged in sequence from first to last according to the process flow sequence, and the pretreatment system is used to carry out impurities removal, dust removal and drying on seeds The processing of; described coating system comprises coating box 50, and described feeding system comprises seed quantitative delivery unit and seed coating agent quantitative delivery unit, and described seed quantitative delivery unit is used for the seed after pretreatment system is sent quantitatively into In the coating box 50 , the seed coating agent quantitative delivery unit is used to quantitatively send the seed coating agent into the coating...

Embodiment 2

[0088] refer to Figure 5 , 8 The difference between this embodiment and the above-mentioned embodiments is that the coating system also includes a mixing unit; a left flap 551 and a right flap 552 are hinged in the coating box 50, and the left flap 551 and the right flap The flap 552 can cooperatively divide the inner cavity of the coating box 50 into a coating chamber and a screening chamber, the left semicircular hole 5511 is opened through on the left flap 551, and the left semicircle hole 5511 is penetrated on the right flap 552. There is a right semicircular hole 5521, and the left semicircular hole 5511 and the right semicircular hole 5521 can cooperate to form a circular hole; the mixing unit includes a second motor 52, a mixing shaft 56, an upper mixing part 53 and a lower mixing part 57 The vertical rotation of the mixing shaft 56 is connected in the coating box 50, and its lower end extends downwards from the coating chamber, and stretches into the screening chambe...

Embodiment 3

[0093] refer to Figure 5-9 , The difference between this embodiment and the above embodiment is that the mixing unit also includes a cylinder 51, an upper sleeve 531, a middle sleeve, a lower sleeve 571, a left connecting rod and a right connecting rod; the piston of the cylinder 51 end is connected with the second motor 52, and can drive the second motor 52 to move up and down; the upper sleeve 531 is located in the coating chamber, and the upper sleeve 531 is rotatably connected to the mixing shaft 56 Perimeter, one end of the upper mixing rod 532 is hinged on the upper sleeve 531, and the upper mixing rod 532 is connected with the upper sleeve 531 by a spring 533; the middle sleeve, the lower sleeve 571 are all located in the sieving chamber and are rotatably connected to the outer periphery of the mixing shaft 56; one end of the lower mixing rod 572 is hinged on the lower sleeve 571, and the lower mixing rod 572 is connected to the lower sleeve 571. The sleeves 571 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com