Method for improving advanced treatment effect on wastewater containing sulfate radical and having high carbon-nitrogen ratio

A high carbon-nitrogen ratio, advanced treatment technology, applied in anaerobic digestion treatment and other directions, can solve the problem of low efficiency of biogas, and achieve the effect of improving the degradation rate of organic matter, inhibiting activity, and reducing enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

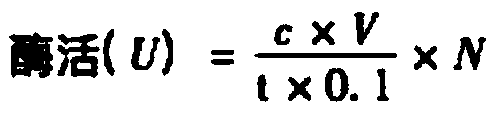

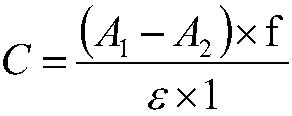

Method used

Image

Examples

Embodiment 1

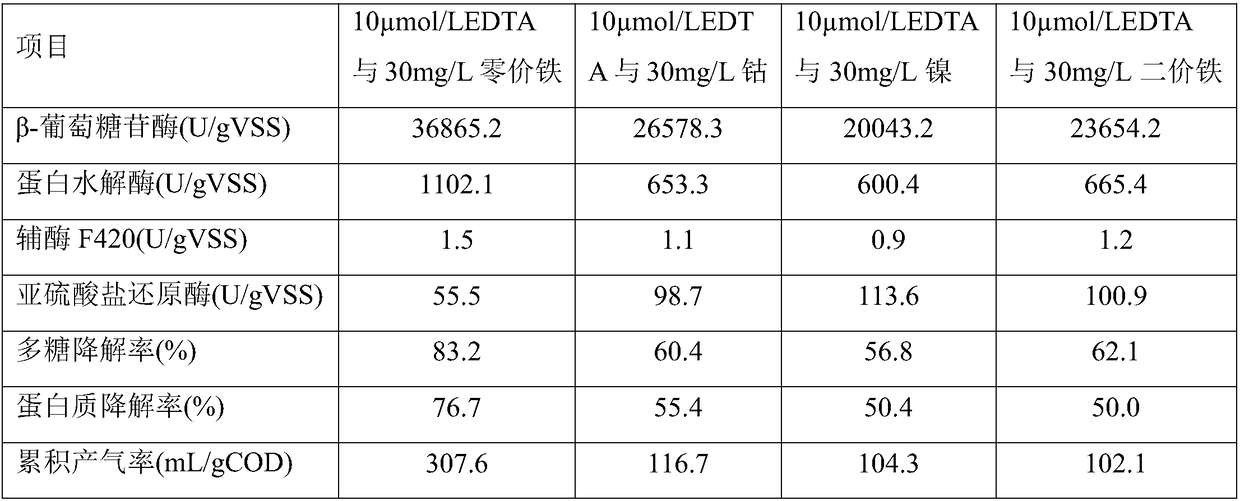

[0045] The influent COD concentration is 6300mg / L, the sulfate concentration is 5000mg / L, the carbon-to-nitrogen ratio is 120, the inoculum concentration of domesticated anaerobic activated sludge is 30mg / L, and 100μmol / LEDTA and 40mg / L zero-valent iron are added , after mixing, seal it with a rubber stopper, and place it in a constant temperature room at 35±1°C to produce biogas anaerobically. When running to the 16th day, β-glucosidase, proteolytic enzyme, coenzyme F 420 The activities of sulfite reductase and sulfite reductase were 39856.0U / gVSS, 1160.0U / gVSS, 1.6U / gVSS and 54.6U / gVSS respectively, and the degradation rates of polysaccharide and protein in the system were 87.3% and 79.3%, respectively. At the same time, the cumulative gas production rate reached 302.2mL / gCOD, an increase of 245.0% compared with the control experiment.

Embodiment 2

[0047] The influent COD concentration is 5180mg / L, the sulfate concentration is 800mg / L, the carbon-to-nitrogen ratio is 50, the inoculum concentration of the domesticated anaerobic activated sludge is 30mg / L, and 1μmol / LEDTA and 10mg / L zero-valent iron are added , after mixing, seal it with a rubber stopper, and place it in a constant temperature room at 35±1°C to produce biogas anaerobically. When running to the 16th day, β-glucosidase, proteolytic enzyme, coenzyme F 420 The activities of sulfite reductase and sulfite reductase were 29896.0U / gVSS, 927.3U / gVSS, 1.3U / gVSS and 78.6U / gVSS respectively, and the degradation rates of polysaccharide and protein in the system were 73.2% and 66.1%, respectively. At the same time, the cumulative gas production rate reached 248.2mL / gCOD, an increase of 183.3% compared with the control experiment.

Embodiment 3

[0049] The influent COD concentration is 5890mg / L, the sulfate concentration is 2800mg / L, the carbon-to-nitrogen ratio is 80, the inoculum concentration of the domesticated anaerobic activated sludge is 30mg / L, and 48μmol / LEDTA and 20mg / L zero-valent iron are added , after mixing, seal it with a rubber stopper, and place it in a constant temperature room at 35±1°C to produce biogas anaerobically. When running to the 16th day, β-glucosidase, proteolytic enzyme, coenzyme F 420 The activities of sulfite reductase and sulfite reductase were 30045.2U / gVSS, 936.4U / gVSS, 1.1U / gVSS and 75.6U / gVSS respectively, and the degradation rates of polysaccharide and protein in the system were 77.6% and 68.9%, respectively. At the same time, the cumulative gas production rate reached 277.7mL / gCOD, an increase of 216.6% compared with the control experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com